Room-temperature-storage type acrylate underfill adhesive and preparation method thereof

A technology of underfill glue and acrylate, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of high cost pressure, affecting product reliability, and high storage and transportation costs, so as to reduce transportation and cost of use, excellent room temperature stability, and low halogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 30 parts of polyurethane modified acrylate resin

[0055] 30 parts of epoxy modified acrylate resin

[0056] 33.5 parts of isobornyl acrylate

[0057] Cumene hydroperoxide 3.0 parts

[0058] p-benzoquinone 0.5 parts

[0059] Leveling agent 1.0 parts

[0060] Defoamer 1.0 parts

[0061] Carbon black paste 1.0 parts

[0062] Preparation:

[0063] Accurately weigh various raw materials according to the proportion of the formula, first add polyurethane modified acrylate resin, epoxy modified acrylate resin, isobornyl acrylate, leveling agent, defoamer, p-benzoquinone, and carbon black slurry to the reaction Stir in the kettle, after stirring evenly, add cumene hydroperoxide, disperse evenly and discharge.

Embodiment 2

[0065] 60 parts of epoxy modified acrylate resin

[0066] 33.5 parts of isobornyl acrylate

[0067] Cumene hydroperoxide 3.0 parts

[0068] p-benzoquinone 0.5 parts

[0069] Leveling agent 1.0 parts

[0070] Defoamer 1.0 parts

[0071] Carbon black paste 1.0 parts

[0072] Preparation:

[0073] Accurately weigh various raw materials according to the proportion of the formula, first add epoxy modified acrylate resin, isobornyl acrylate, leveling agent, defoamer, p-benzoquinone, and carbon black paste into the reaction kettle and stir until they are evenly stirred Finally, add cumene hydroperoxide, disperse evenly and discharge.

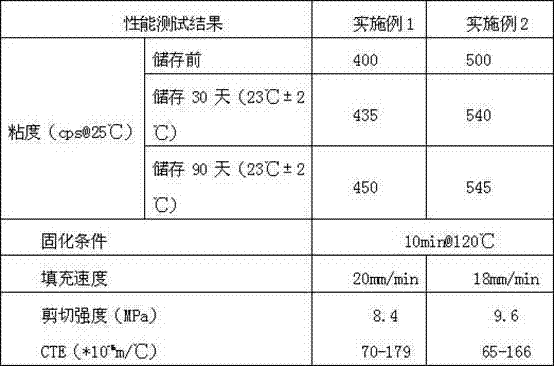

[0074] Examples listed in Table 1 and performance test results after curing thereof. The test results show that the underfill of the present invention has good storage stability, low viscosity, excellent process adaptability and good reliability, and can fully meet the process requirements of SMT.

[0075] Table 1

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com