Lubricating grease specially used in high-temperature kiln car, and preparation method thereof

A lubricating grease and high-temperature kiln technology, applied in the field of lubricating grease, can solve problems such as increased labor intensity, time and manpower consumption, and bearing failure, and achieve excellent colloidal stability, low-temperature pumpability, and excellent colloidal stability and pumpability, good high temperature oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

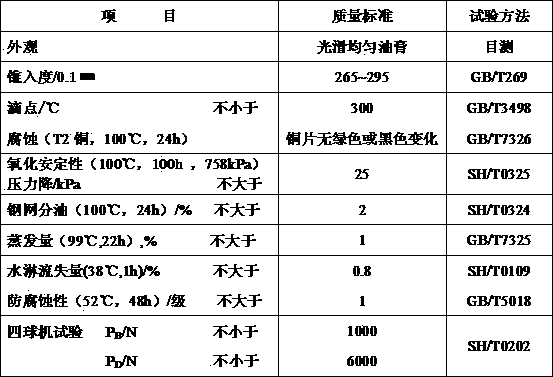

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention are described below to facilitate the understanding of those skilled in the art.

[0022] A lubricating grease method specially used for high-temperature kiln cars. The raw materials of the lubricating grease and the ratios of parts by weight of each component are: 40-60 parts of base oil A, 30-50 parts of base oil B, 4-octadecylamine 8 parts, 3-5 parts of ethylenediamine, 3-6 parts of MDI (diphenylmethane-4,4'-diisocyanate), 1-2 parts of antioxidant A, 2-3 parts of antioxidant B, antirust 2-3 parts of anti-wear agent, 1-2 parts of extreme pressure anti-wear agent A, 1.5-3 parts of extreme pressure anti-wear agent B, 5-10 parts of tackifier, base oil A is high-viscosity and deeply refined mineral oil 150BS, so The base oil B is PAO synthetic oil, the antioxidant A is diphenylamine, the antioxidant B is butyl octyl zinc salt, the rust inhibitor is alkenyl succinic acid, and the extreme pressure resistance The grinding age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com