Manufacturing method of multi-U sodium lamp inner tube and compact-type plasma sodium lamp adopting same

A manufacturing method and technology of plasma sodium, which are applied in the manufacture of ships or lead wires, parts of gas discharge lamps, low-pressure discharge lamps, etc., can solve the problems of low surface brightness, long overall length and low surface brightness of low-pressure sodium lamps, etc. To achieve the effect of increasing the surface brightness of the lamp body, good contrast, and improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] Specific implementation mode one: see Figure 1 to Figure 4 , the manufacturing method of the multi-U sodium lamp inner tube of the present embodiment, the specific steps are:

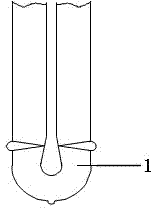

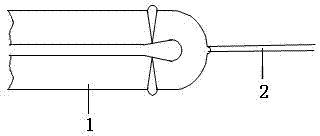

[0050]Step 1. Bending tube: According to the power of the light source to be produced, select the anti-sodium glass tube (the length of the anti-sodium glass tube required by different specifications of sodium light source lamps is different), and place the anti-sodium glass tube on the U-shaped bend On the tube machine, manually operate the button on the U-shaped tube bending machine, the anti-sodium glass tube rotates, and the flame heats the soda-resistant glass tube from the bottom. Shaped sodium-resistant glass tube 1 (see figure 1 ), manually take out the U-shaped sodium-resistant glass tube and send it to the annealing furnace for annealing, and then connect the exhaust rod 2 to the U-shaped sodium-resistant glass tube 1 (see figure 2 );

[0051] Step 2, sealing: preparation work, con...

specific Embodiment approach 2

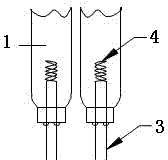

[0057] Specific implementation mode two: see Figure 5 with Image 6 In this embodiment, this embodiment is realized based on the inner tube of the multi-U sodium lamp prepared by the method described in Embodiment 1, specifically:

[0058] The compact plasma sodium lamp of this embodiment includes a glass outer tube body 7, a lamp cap 8 and a sodium lamp inner tube 9, the number of the sodium lamp inner tubes 9 is multiple, the glass outer tube body 7 is set on the sodium lamp inner tube 9, and the lamp cap 8 It is arranged at the outer end of the tail of the glass outer tube body 7, and the lamp cap 8 is electrically connected with the sodium lamp inner tube 9; the inner wall of the glass outer tube body 7 is sprayed with tin oxide far-infrared reflective film by plasma spraying method.

[0059] The tin oxide far-infrared reflective film sprayed on the inner wall of the glass outer tube body 7 has the advantages of no pollution and high density, and the tin oxide far-infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com