Wet preparation process of infant formula milk powder

An infant formula and preparation technology technology, which is applied in the field of wet preparation technology of infant formula milk powder, can solve the problems of mildew, unpleasant odor, darkening of milk powder and the like, achieves good stability, prevents adverse reactions, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The ingredient ratio of infant formula milk powder is as follows: vegetable oil 20g, wall material: lactose 20g; fresh milk containing 11.1% dry matter 187g; desalted whey powder 25g; whey protein powder 4g; lactose 4.993g; oligosaccharides 2.5g; Compound mineral 0.7g, wall material: lecithin 0.35g; multivitamin 0.1g, wall material: whey protein powder 0.4g; nutrient 0.3g, wall material: desalted whey powder 0.6g, corn syrup 0.3g.

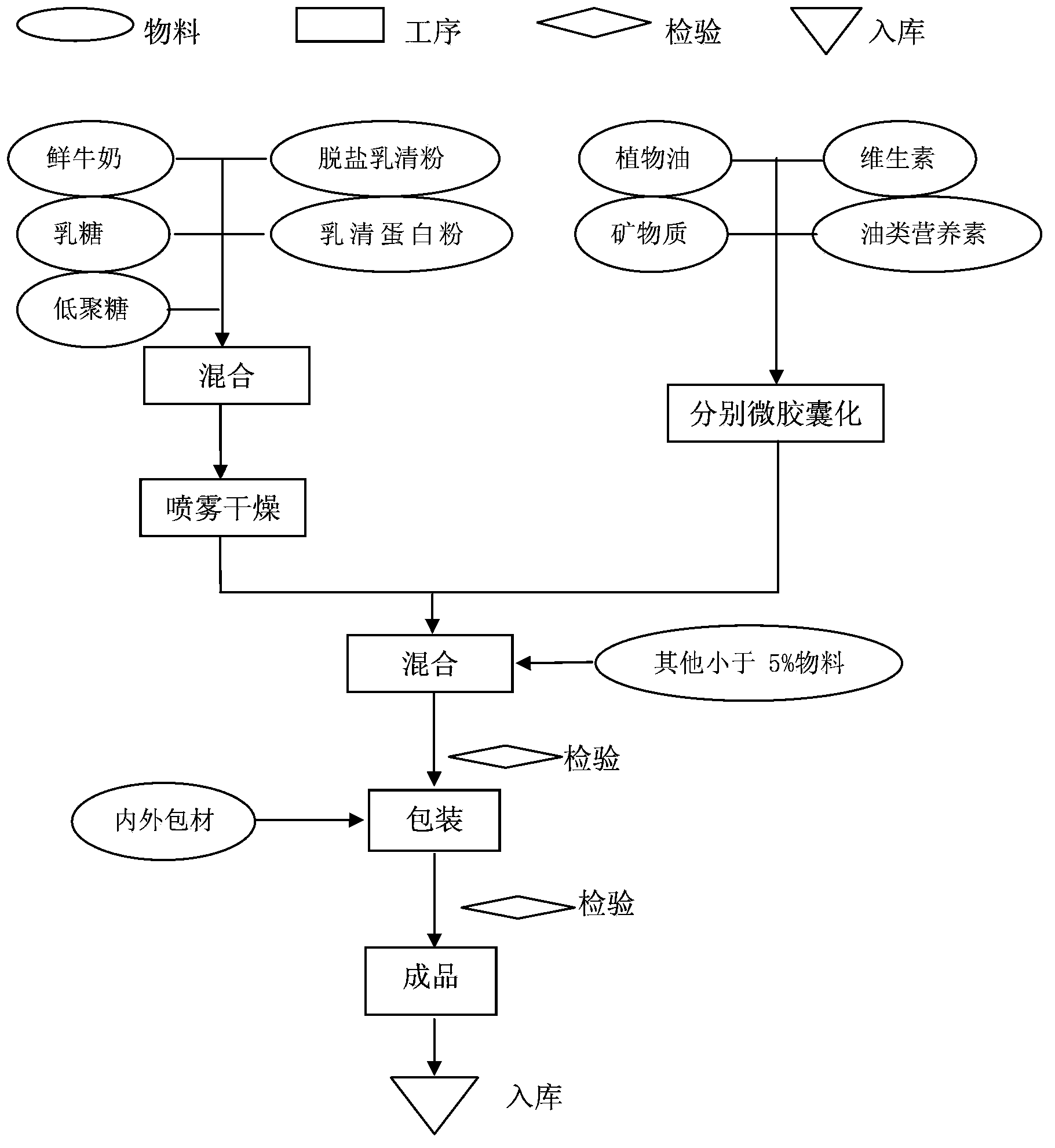

[0031] refer to figure 1 See the preparation process as follows:

[0032] (1) Vitamin microcapsule technology: First, add whey protein powder into purified water and dissolve it into a whey protein solution with a mass fraction of 10%, then add a multivitamin whose wall material ratio is 4:1 to the core material; Spray drying, operation control inlet temperature 120°C, outlet temperature 50°C, cooling to get vitamin powder;

[0033] (2) Mineral microcapsule technology: Dissolve the added minerals in a small amount of purified water to make...

Embodiment 2

[0040] The ingredient ratio of infant formula milk powder is as follows: vegetable oil 20g, wall material: lactose 20g; fresh milk containing 11.1% dry matter 187g; desalted whey powder 25g; whey protein powder 4g; lactose 4.143g; oligosaccharides 2.5g; Compound mineral 0.7g, embedding wall material: lecithin 0.7g; multivitamin 0.1g, embedding wall material: whey protein powder 0.6g; nutrient 0.3g, embedding wall material: desalted whey powder 0.8g, corn Syrup 0.4g.

[0041] refer to figure 1 See the preparation process as follows:

[0042] (1) Vitamin microcapsule technology: First, add whey protein powder into purified water to dissolve it into a whey protein solution with a mass fraction of 10%, then add a multivitamin whose wall material ratio is 6:1 to the core material; Spray drying, the inlet temperature is controlled at 120°C, the outlet temperature is 50°C during operation, and the vitamin powder is obtained after cooling;

[0043] (2) Mineral microcapsule technolo...

Embodiment 3

[0050] The ingredients of infant formula milk powder are as follows: vegetable oil 5g, wall material: desalted whey powder 5g; fresh milk containing 11.1% dry matter 427g; desalted whey powder 20g; whey protein powder 2g; Sugar 1.5 g; compound minerals 0.35 g, wall material: lecithin 0.28 g; multivitamin 0.15, wall material: maltodextrin 0.75 g; nutrients 0.5 g, wall material: whey protein powder 0.75 g, lactose 0.25 g.

[0051] The preparation process is as follows:

[0052] (1) Vitamin microcapsule technology: First, maltodextrin is added to purified water to dissolve into a solution with a mass fraction of 20%, and then mixed with multivitamin and wall material to core material at a ratio of 5:1, spray-dried at low temperature, and cooled Then get vitamin powder;

[0053] (2) Mineral microcapsule technology: Dissolve the added minerals in a small amount of purified water to make a suspension, then disperse lecithin with 0.8 times the mineral mass in the mineral suspension,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com