Preparation method of nano cuprous oxide photocatalyst

A nano-cuprous oxide, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., achieves short time-consuming, simple and readily available raw materials, and conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

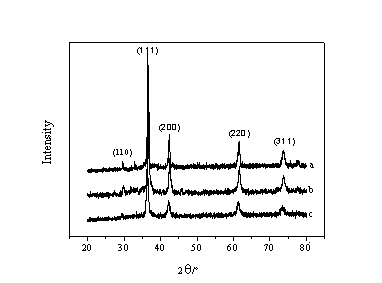

[0032] The steps of preparing nano-cuprous oxide photocatalyst are the same as those in Example 1, wherein the amount of deionized water is 452.5 mL, and the amount of NH 2 OH·HCl is 32.5 mL 0.2 mol / L, centrifuged, washed and dried to obtain sample b. The morphology of the catalyst is a chamfered cube with an average particle size of about 300 nm.

Embodiment 3

[0034] The steps of preparing nano-cuprous oxide photocatalyst are the same as those in Example 1, wherein the amount of deionized water is 437.5 mL, and the amount of NH 2 OH·HCl is 47.5 mL 0.2 mol / L, centrifuged, washed and dried to obtain sample c. The morphology of the catalyst is cubo-octahedron, and the average particle size is about 220 nm.

[0035] The catalysts prepared in the above examples were respectively used in the following photocatalytic degradation experiments to investigate the catalytic activity of each catalyst:

[0036] Reaction 1: Weigh 0.01 g of catalyst a, add 100 mL of 4-chlorophenol aqueous solution with an initial concentration of 12.8 mg / L, pH 5.0, and ultrasonically disperse it for about 20 min in a dark room to completely disperse the catalyst in the solution to form an emulsion, And reach saturation adsorption, the reaction temperature is maintained by circulating water bath. Samples were taken regularly, centrifuged, and the supernatant was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com