Preparation method of magnetic fat hydrogenation catalyst

A technology of oil hydrogenation and catalyst, which is applied in the field of oil hydrogenation catalysis, can solve the problems of catalyst loss, production cost, improvement, and influence on the quality of hydrogenated oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 920 g of absolute ethanol and 1080 g of deionized water were uniformly mixed to obtain an alcohol-water mixed solution. Mix 20g of magnetic powder Fe under high-speed stirring 3 o 4 Dispersed into alcohol-water mixed solution.

[0017] Adjust the pH of the solution to 7.5 with ammonia water, and slowly add 104 g of tetraethyl orthosilicate solution to the solution dropwise under high-speed stirring at a controlled reaction temperature of 70°C. After the addition, it is aged for 3.0 hours, filtered, washed with alcohol, and dried. Obtain SiO2 / Fe3O4 composite carrier.

[0018] Add 1000mL of base water into the reaction kettle, start stirring and heating the system to 80°C, add 1000mL of nickel nitrate solution with a concentration of 0.32mol / L, 500mL of Na with a concentration of 0.4mol / L 2 CO 3 The solution was added dropwise into the reaction kettle at a uniform speed, and the feeding time was controlled within 1.0 hour. After all the raw material liquid was added, ...

Embodiment 2

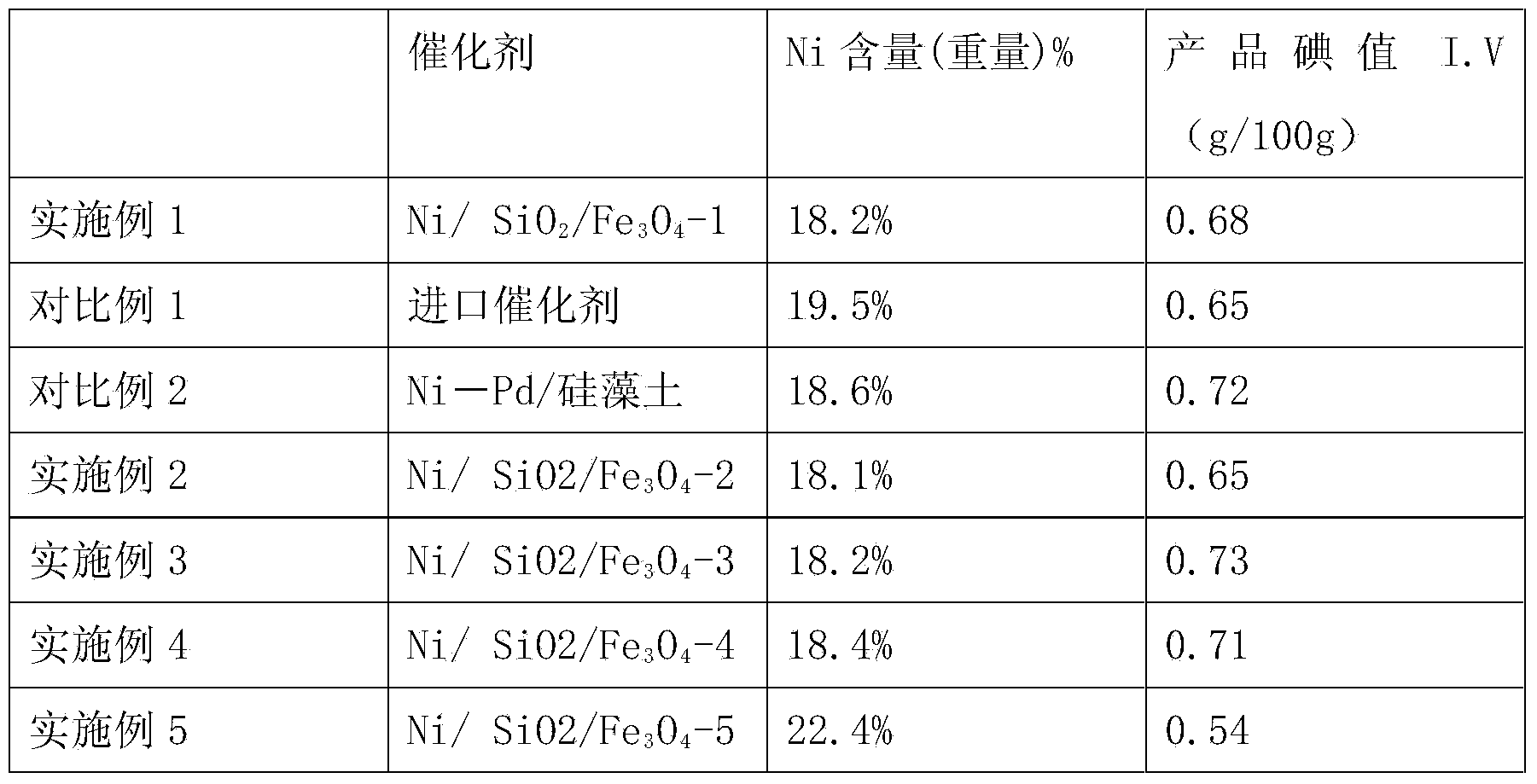

[0024] 1200g of isopropanol and 800g of deionized water were evenly mixed to obtain an alcohol-water mixed solution. Mix 20g of magnetic powder Fe under high-speed stirring 3 o 4 Dispersed into alcohol-water mixed solution. Other steps are with embodiment 1. The evaluation results of hydrogenation reaction of palm oil are shown in Table 1.

Embodiment 3

[0026] With 20g magnetic powder Fe in embodiment 1 3 o 4 Add-on changes 30g into, other is with embodiment 1. The evaluation results of hydrogenation reaction of palm oil are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com