Modified phenol formaldehyde resin thermal insulation board and preparation method thereof

A technology of phenolic resin and thermal insulation board, which is applied in the field of building thermal insulation materials, can solve the problems of failure to exert effective fire protection performance, unfavorable long-term use, inconvenience in construction and transportation, etc., and achieves convenience in transportation and construction operations, enhanced rigidity, and performance The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

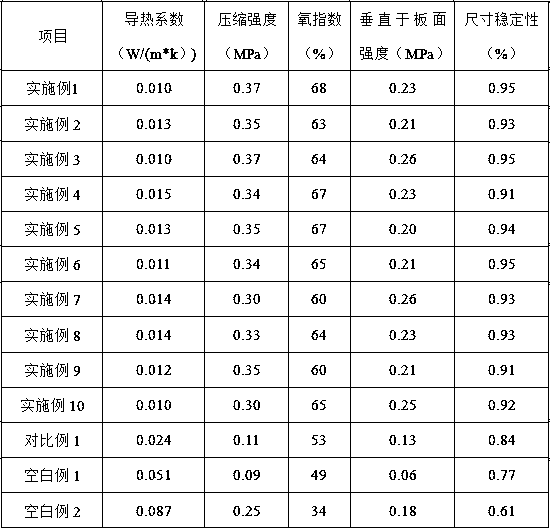

Examples

Embodiment 1

[0032] A kind of modified phenolic resin insulation board of embodiment 1, it is prepared by following method:

[0033] Take by weighing 64kg of nanoclay and 112kg of deionized water, fully stir and mix; add 25wt% ammonia water to adjust the pH of the solution to 8, and obtain the modified solution;

[0034] Peel the willow branches and immerse them in the above-mentioned modifying solution; apply constant temperature and pressure at 0.12 MPa and 25°C for 48 hours, at this time, the nano-clay in the modifying solution is brown-black; take out the willow branches and crush them to a length of 2-3mm , a strip fiber with a thickness of 0.5-1 mm, dried to obtain modified willow fiber;

[0035] Take by weighing 15 kg of the above-mentioned modified willow fiber, 80 kg of phenolic resin, 30 kg of hollow glass microspheres with a particle diameter of 50-80 μm, 5 kg of calcium carbonate and 3 kg of surfactant, and mix to obtain a mixture; add 95kg of deionized water was fully stirred...

Embodiment 2

[0038] A kind of modified phenolic resin insulation board of embodiment 2, it is prepared by following method:

[0039] Take by weighing 70kg of nanoclay and 123kg of deionized water, fully stir and mix; add 25wt% ammonia water to adjust the pH of the solution to 8, and obtain the modified solution;

[0040] Peel the willow branches and immerse them in the above-mentioned modifying solution; apply constant temperature and pressure at 0.13 MPa and 30°C for 48 hours, at this time, the nano-clay in the modifying solution is brown-black; take out the willow branches and crush them to a length of 2-3mm , a strip fiber with a thickness of 0.5-1 mm, dried to obtain modified willow fiber;

[0041]Take by weighing 20 kg of the above-mentioned modified willow fiber, 100 kg of phenolic resin, 35 kg of vitrified microbeads with a particle diameter of 50-80 μm, 6 kg of water glass and 3 kg of surfactant, and mix to obtain a mixture; add 123kg of deionized water was fully stirred evenly to...

Embodiment 3

[0044] A kind of modified phenolic resin insulation board of embodiment 3, it is prepared by following method:

[0045] Take by weighing 80kg of nanoclay and 140kg of deionized water, fully stir and mix; add 25wt% ammonia water to adjust the pH of the solution to 8, and obtain the modified solution;

[0046] Peel the willow branches and immerse them in the above-mentioned modifying solution; apply constant temperature and pressure at 0.13 MPa and 40°C for 48 hours, at this time, the nano-clay in the modifying solution is brown-black; take out the willow branches and crush them to a length of 2-3mm , a strip fiber with a thickness of 0.5-1 mm, dried to obtain modified willow fiber;

[0047] Take by weighing 20kg of the above-mentioned modified willow fiber, 120 kg of phenolic resin, 45 kg of expanded perlite with a particle size of 50-80 μm, 6 kg of silicon carbide and 5 kg of surfactant, and mix to obtain a mixture; add 147kg deionized water, fully stirred evenly, to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com