Positive electrode slurry, positive electrode plate and lithium battery

A technology of positive electrode slurry and positive electrode sheet, which is used in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of hard and brittle positive electrode sheets, and excessively thick coating of positive electrode slurry and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

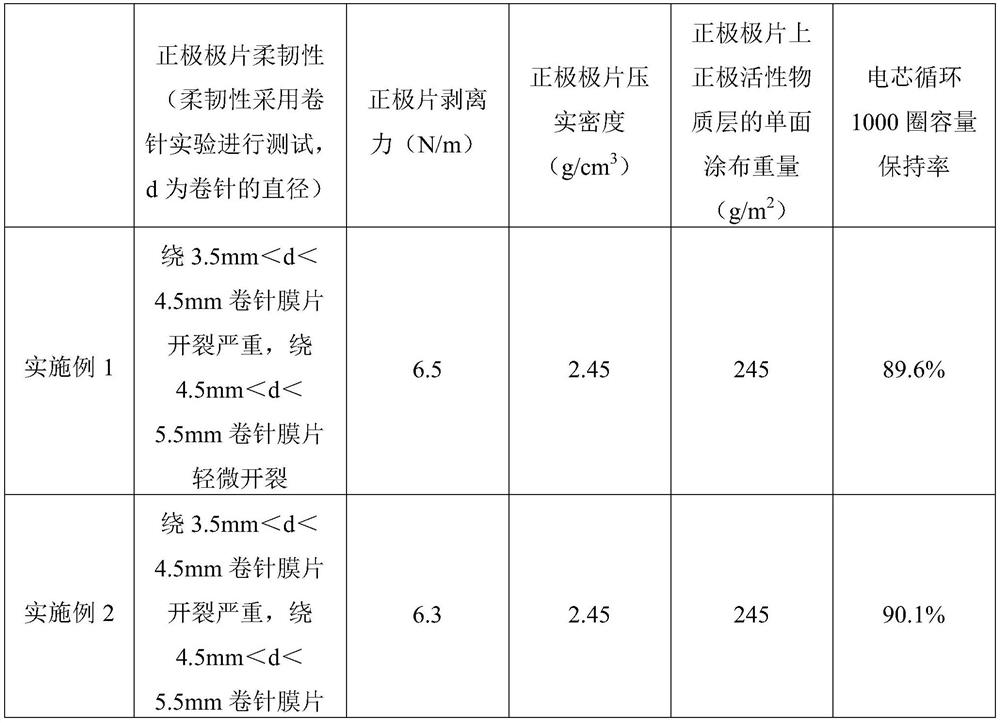

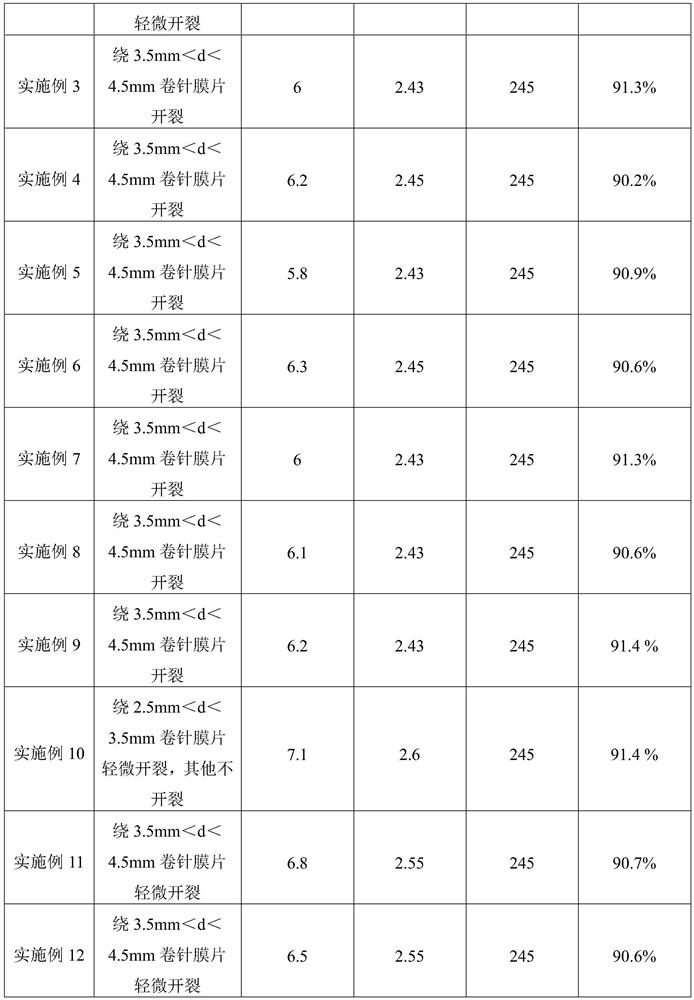

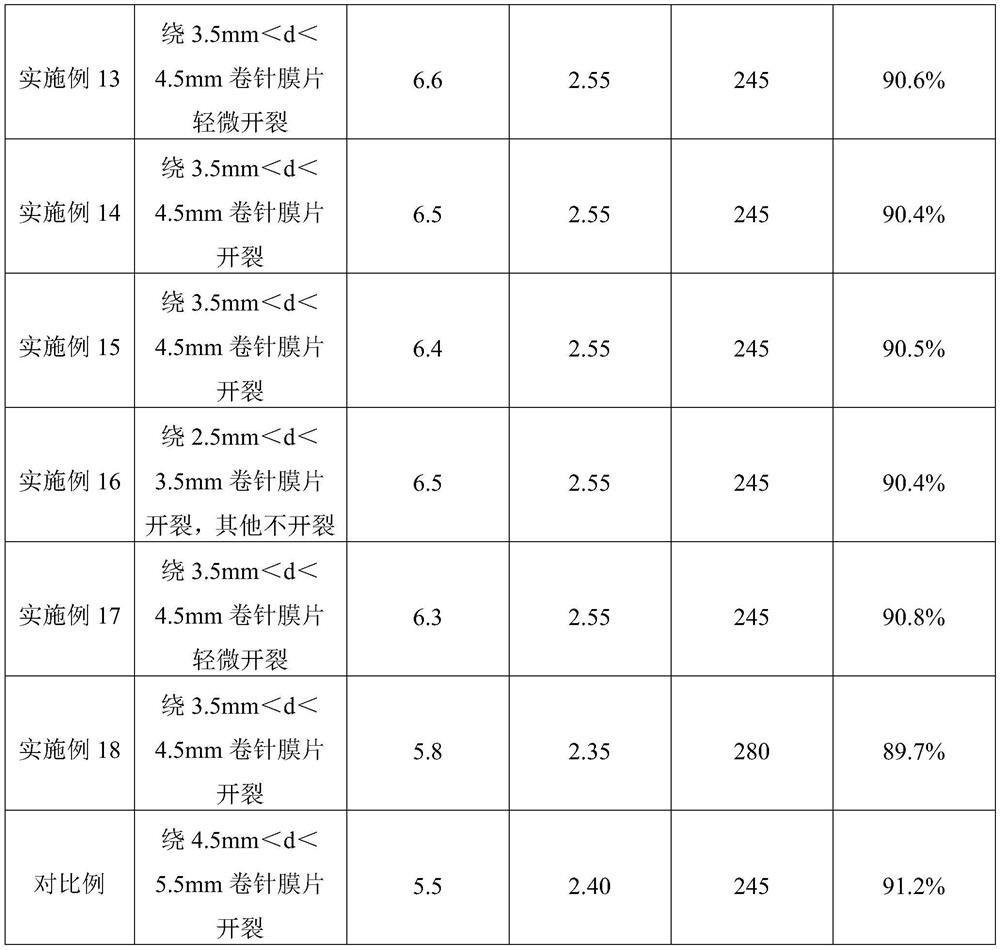

Examples

Embodiment 1

[0033] The positive electrode slurry includes: 96.5% by weight of lithium iron phosphate, 3% by weight of binder and 0.5% by weight of conductive carbon black, wherein the binder includes PVDF and additive ethylene glycol, and the mass ratio of PVDF and additive is 87:13;

[0034] The method for preparing the positive electrode sheet: by coating the above-mentioned positive electrode slurry on both surfaces of the aluminum foil, and rolling after the coating is completed, a positive electrode active material layer can be formed on the surface of the aluminum foil. The single-sided coating weight is 245g / m 2 the positive pole piece;

[0035] Cell preparation: take the above positive pole piece as the positive pole, graphite as the negative pole, pp film as the diaphragm, the electrolyte includes lithium hexafluorophosphate, ethylene carbonate, dimethyl carbonate and cyclic methyl ethyl carbonate, wherein the concentration of lithium hexafluorophosphate in the electrolyte is 1m...

Embodiment 2

[0037] The additive is ethanol, and the rest are the same as in Example 1.

Embodiment 3

[0039] The additive is ethylamine, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com