Super-hard semiconductor material polishing method

A semiconductor and superhard technology, which is applied in semiconductor/solid-state device manufacturing, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as scratches, achieve high flatness, reduce costs, and increase yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

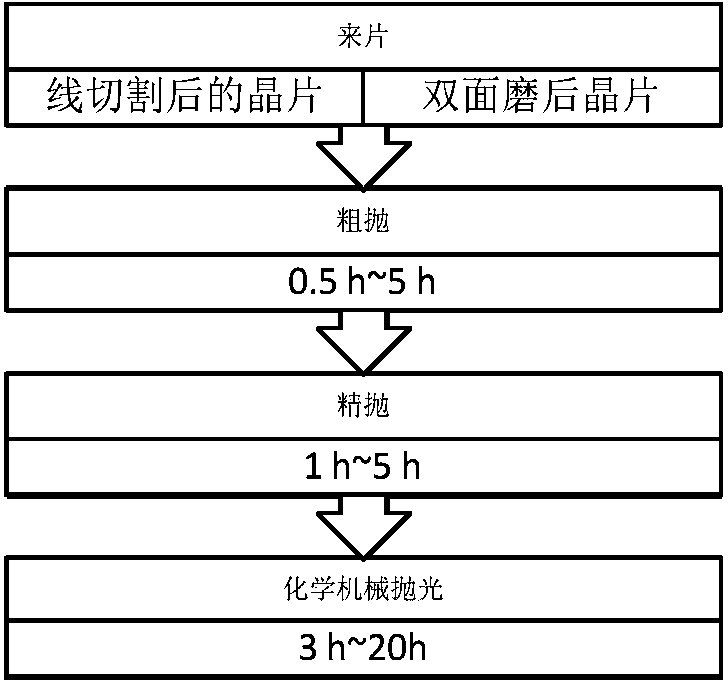

Method used

Image

Examples

Embodiment 1

[0032] The ultra-hard semiconductor material SiC wafer with a thickness of 450 ± 10 μm, a line mark depth of less than 10 μm, a warpage of less than 50 μm, and a thickness non-uniformity of less than 30 μm after wire cutting is polished using the process described in the present invention: first, use The diamond polishing liquid with a pH value of 7.0, a concentration of 20%, and a particle size of 5 μm uses a polishing cloth with a Shore hardness of 70, and the polishing pressure is controlled at 5 g / cm 2 , the rotational speed of the polishing disc is 80 rpm, and rough polishing is performed for 5 hours. Then use a diamond polishing liquid with a pH value of 7.0, a concentration of 20%, and a particle size of 2 μm, using a polishing cloth with a Shore hardness of 60, and controlling the polishing pressure to 5 g / cm 2 , the rotational speed of the polishing disc is 70rpm, and the fine polishing is carried out for 5h. Then, the silica sol with a pH value of 9.5, a concentrati...

Embodiment 2

[0034] For wire-cut superhard semiconductor material Al with a thickness of 450±10 μm, a line trace depth of less than 10 μm, a warpage of less than 50 μm, and a thickness unevenness of less than 30 μm 2 o 3 The wafer is polished by the process described in the present invention: first, the diamond polishing liquid with a pH value of 7.0, a concentration of 20%, and a particle diameter of 5 μm is used, and a polishing cloth with a Shore hardness of 70 is used, and the controlled polishing pressure is 5 g / cm 2 , the rotational speed of the polishing disc is 80 rpm, and rough polishing is performed for 5 hours. Then use a diamond polishing liquid with a pH value of 7.0, a concentration of 20%, and a particle size of 2 μm, using a polishing cloth with a Shore hardness of 60, and controlling the polishing pressure to 5 g / cm 2 , the rotational speed of the polishing disc is 70rpm, and the fine polishing is carried out for 5h. Then, the silica sol with a pH value of 9.5, a concent...

Embodiment 3

[0036] The ultra-hard semiconductor material SiC wafer with a thickness of 450 ± 10 μm, a line mark depth of less than 10 μm, a warpage of less than 50 μm, and a thickness non-uniformity of less than 30 μm after wire cutting is polished using the process described in the present invention: first, use The diamond polishing liquid with a pH value of 3.0, a concentration of 3%, and a particle size of 1.5 μm uses a polishing cloth with a Shore hardness of 70, and the polishing pressure is controlled at 2 g / cm 2 , the rotational speed of the polishing disc was 30 rpm, and rough polishing was performed for 7 hours. Then use a diamond polishing liquid with a pH value of 7.0, a concentration of 20%, and a particle size of 2 μm, using a polishing cloth with a Shore hardness of 60, and controlling the polishing pressure to 5 g / cm 2 , the rotational speed of the polishing disc is 70rpm, and the fine polishing is carried out for 5h. Then, the silica sol with a pH value of 9.5, a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com