Fractional extraction method for honey pomelo peel polysaccharides, product thereof and application of product

A grading method, the technology of pomelo peel polysaccharide, applied in the application, food science, tobacco and other directions, to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1. Take pomelo peel, add 1.5% cellulase and 1.5% pectinase according to the weight of pomelo peel, add water at 50°C, the weight ratio of water and pomelo peel is 25:1, high shear Dispersing and emulsifying machine 10000r / min under the treatment of 10min, enzymatic hydrolysis for 1.5 hours, to obtain enzymatic hydrolysis liquid, take a part of the enzymatic hydrolysis liquid, leaching, to obtain a polysaccharide content of 9.49%

[0040] S2. Take the enzymolysis solution obtained from S1, add ethanol so that the concentration of ethanol in the solution is 45~55%, ethanol analysis at a temperature of 25°C-4°C, centrifuge, and centrifuge to obtain a precipitate 1 and a supernatant 1, and the obtained precipitate Object one is that the yield of a crude polysaccharide is 13.12%, the purity of the polysaccharide in the a crude polysaccharide is 42.2%, and the yield of a polysaccharide after purification is 5.6%,

[0041]S3. Take the supernatant liquid 1 obtained in step S2...

Embodiment 2

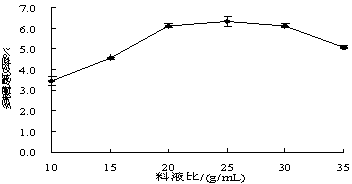

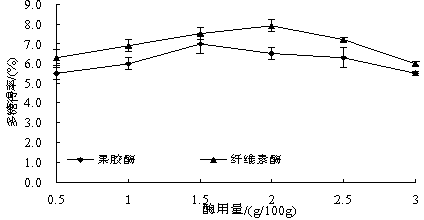

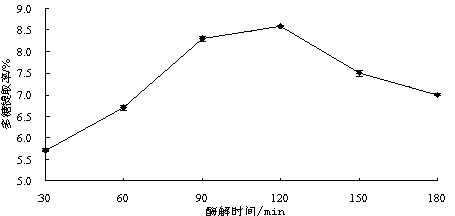

[0044] Example 2 Effects of solid-liquid ratio, enzyme amount, enzymatic hydrolysis time and enzymatic hydrolysis temperature on extraction.

[0045] 1. Materials

[0046] The honey pomelo was collected from the pomelo garden in Meizhou, and the honey pomelo with the same variety, size, uniform fruit color, basically the same maturity, no mechanical damage, no disease and pest infestation was selected as the test material. After the peel is cut into thin slices, it is dried in a constant temperature drying oven, and it is ground into powder by a pulverizer for later use. Reagents were analytically pure glucose, absolute ethanol, propylene glycol, 5% phenol, concentrated sulfuric acid, deionized water, chloroform, n-butanol, activated carbon, etc. were purchased from Guangzhou Yima Biotechnology Co., Ltd. Pectinase: Tianjin Enzyme Preparation Factory; Cellulase: Shanghai Boao Biotechnology Co., Ltd.

[0047] 2. Instrument

[0048] DU-730 UV-Vis Spectrophotometer (S...

Embodiment 3

[0097] Example 3 Application of a polysaccharide, b polysaccharide and c polysaccharide in keeping tobacco moist

[0098] 1. Determination of self-moisture retention of pomelo peel polysaccharides of different grades

[0099] Using 30% ethanol and deionized water as solvents respectively, at room temperature, take 2 g each of crude polysaccharide a, crude polysaccharide b, and crude polysaccharide c with a concentration of 1.5%, and 2 g each of 0.2% propylene glycol and 1.5% propylene glycol as The control group was placed in a watch glass, a total of 8 groups. At room temperature, every 1h, the samples were taken out and weighed, and the water loss rate was calculated according to the formula: water loss rate (%)=(M 1 -M 2 ) / M 3 ×100.

[0100] (where: M 1 is the total weight of the sample before placing; M 2 is the total weight of the sample after being placed for different times; M 3 is the net weight of the sample)

[0101] The specific effect is shown in Fig. Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com