Mirtazapine tablet and preparation method thereof

A kind of mirtazapine tablet, the technology of mirtazapine, applied in the field of mirtazapine tablet and its preparation, can solve the problems such as the reduction of mirtazapine clearance rate, achieve the effect of low production cost, simple preparation and operation, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

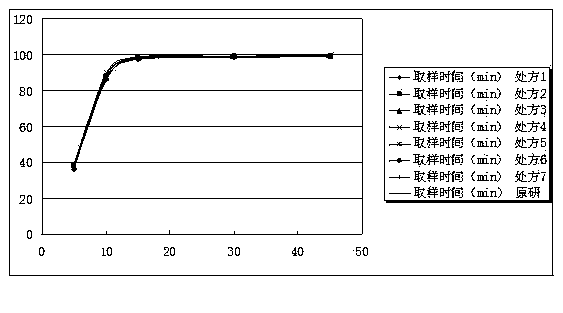

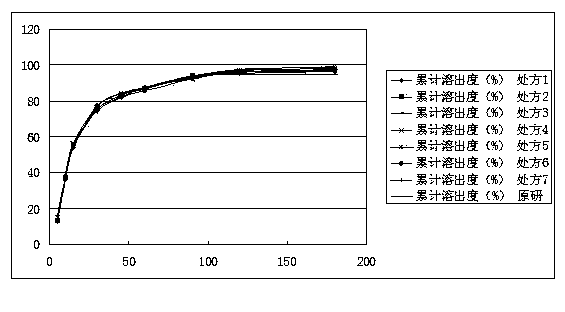

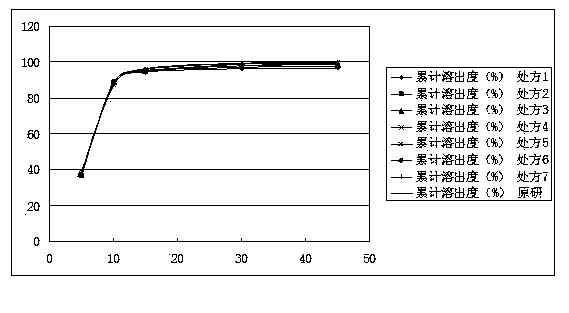

Image

Examples

Embodiment 1

[0033] Mirtazapine 30g

[0034] Lactose 40g

[0035] Starch 200g

[0036] 10% hydroxypropyl cellulose aqueous solution 200ml

[0037] Magnesium stearate 0.75g

[0038] Micronized silica gel 0.75g

[0039] Preparation method: pass lactose and starch through an 80-mesh sieve; micronized mirtazapine (determination of particle size: Dav=16.552, D 10 =6.720μm, D 50 =15.221μm, D 90 =33.190μm) mixed with lactose and starch according to equal increment method; add 10% hydroxypropyl cellulose aqueous solution to make soft material; granulate with 24 mesh sieve; 3 times; 20-mesh sieve for granulation; add prescription amount of magnesium stearate and micropowder silica gel to the granules after granulation, mix evenly, and compress into tablets. The formulation was coated with gastric-soluble Opadry using conventional coating equipment.

Embodiment 2

[0041] Mirtazapine 30g

[0042] Lactose 180g

[0043] Starch 70g

[0044] 10% hydroxypropyl cellulose aqueous solution 120ml

[0045] Magnesium Stearate 1.5g

[0046] Micronized silica gel 0.75g

[0047] Preparation method: pass lactose and starch through an 80-mesh sieve; micronized mirtazapine (determination of particle size: Dav=18.453, D 10 =7.291μm, D 50 =17.195μm, D 90=35.184μm) mixed with lactose and starch according to equal increment method; add 10% hydroxypropyl cellulose aqueous solution to make soft material; granulate with 24 mesh sieve; 3 times; 20-mesh sieve for granulation; add prescription amount of magnesium stearate and micropowder silica gel to the granules after granulation, mix evenly, and compress into tablets. The formulation was coated with gastric-soluble Opadry using conventional coating equipment.

Embodiment 3

[0049] Mirtazapine 30g

[0050] Lactose 160g

[0051] Starch 100g

[0052] 8% hydroxypropyl cellulose aqueous solution 100ml

[0053] Magnesium stearate 1.2g

[0054] Micronized silica gel 1.2g

[0055] Preparation method: pass lactose and starch through an 80-mesh sieve; micronized mirtazapine (determination of particle size: Dav=19.142, D 10 =6.560μm, D 50 =18.814μm, D 90 =37.510μm) mixed with lactose and starch according to equal increment method; add 10% hydroxypropyl cellulose aqueous solution to make soft material; granulate with 24 mesh sieve; 3 times; 20-mesh sieve for granulation; add prescription amount of magnesium stearate and micropowder silica gel to the granules after granulation, mix evenly, and compress into tablets. The formulation was coated with gastric-soluble Opadry using conventional coating equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com