High-impact-toughness cubic boron nitride, synthetic method and application thereof

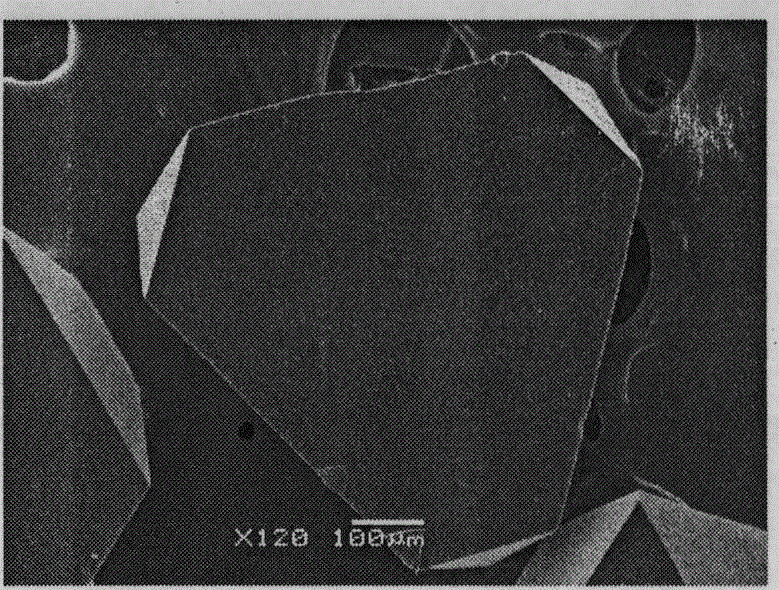

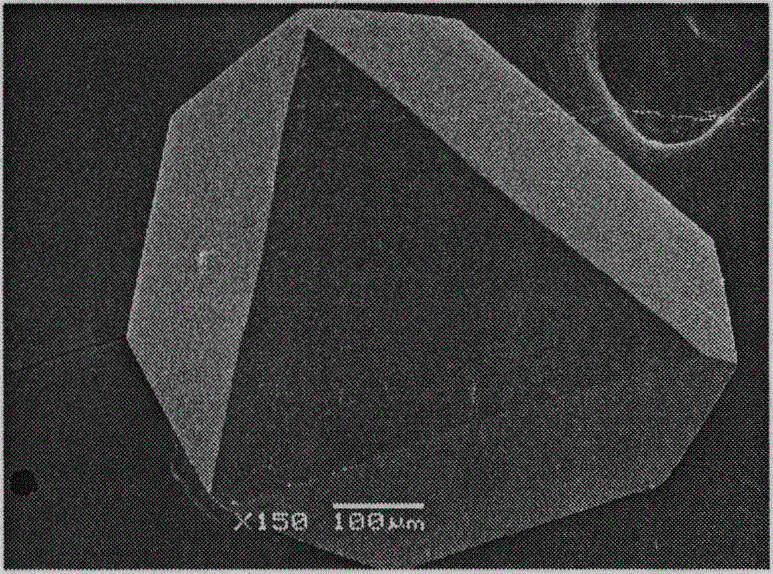

A technology of cubic boron nitride and a synthesis method, which is applied in chemical instruments and methods, technological processes using ultra-high pressure, and single crystal growth, etc., can solve the problems of many defects, irregular crystal shape of cBN crystals, and low impact toughness of cBN crystals. , to achieve the effect of less defects and impurities, high industrial production value, and high crystal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

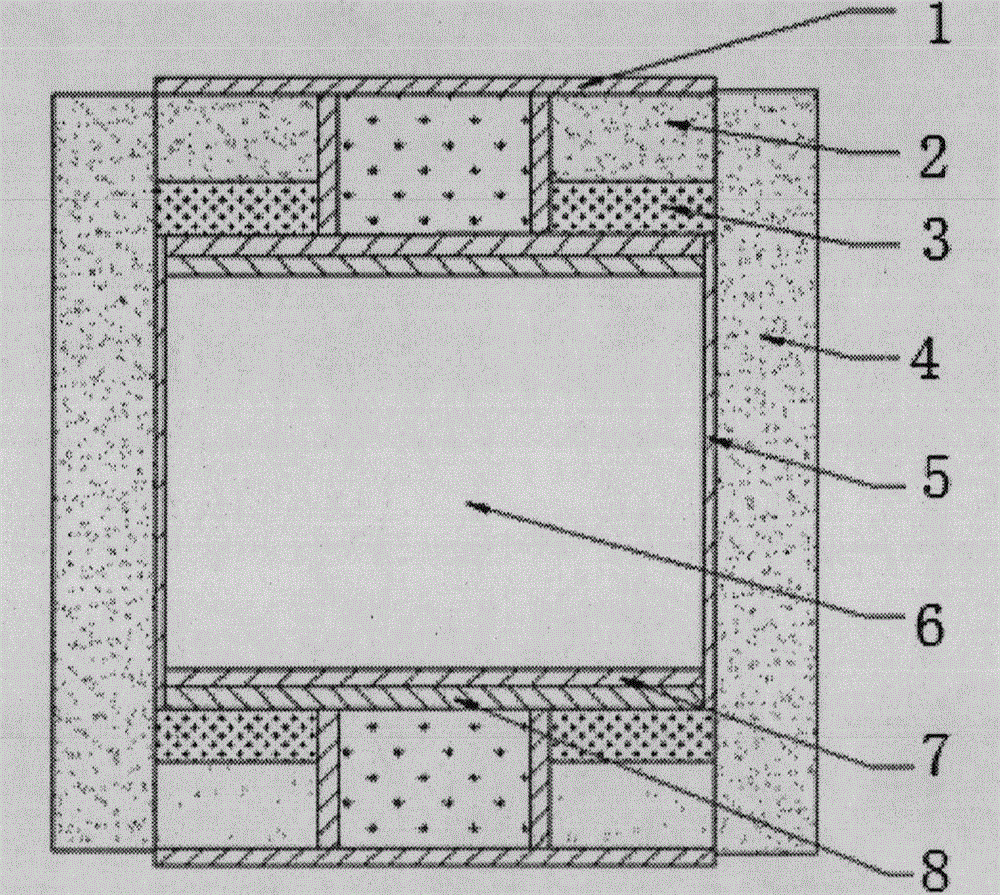

Method used

Image

Examples

Embodiment 1

[0038] A preliminary preparation

[0039] 1) Li with a particle size of 80 μm 3 N catalyst powder and hBN content 98% by mass ratio, B 2 o 3 The high-purity hexagonal boron nitride powder with a particle size of 20 μm and a content of 0.5% is weighed at a weight ratio of 1:9, put into a mortar and evenly mixed with a spoon to form a mixed powder;

[0040] 2) Put the hand-mixed powder into an inclined, uniformly rotating mixer for mixing; the time is 4 hours; during the mixing process, attention should be paid to the tightness of the sample, in order to avoid Li 3 N reacts with water in the air, and vacuumizes the mixing tank;

[0041]3), because hBN is a barren raw material, the molding performance is relatively poor; the mixed powder mixed in step 2) is sealed, and isostatically pressed on a frame-type cold isostatic press with a pressure of 120Mpa, and the isostatic pressing molding can Form the barren powder into a compact green body;

[0042] 4) Weigh the powder with ...

Embodiment 2

[0055] A preliminary preparation

[0056] 1) Li with a particle size of 90 μm 3 N catalyst powder and hBN content 99% by mass ratio, B 2 o 3 The high-purity hexagonal boron nitride powder with a particle size of 25 μm and a content of 0.4% is weighed at a weight ratio of 1:10, put into a mortar and evenly mixed with a spoon to form a mixed powder;

[0057] 2) Put the hand-mixed powder into an inclined, uniformly rotating mixer for mixing; the time is 5 hours; during the mixing process, attention should be paid to the tightness of the sample, in order to avoid Li 3 N reacts with water in the air, and vacuumizes the mixing tank;

[0058] 3), because hBN is a barren raw material, the molding performance is relatively poor; the step 2) is mixed uniformly and sealed, and isostatically pressed with a pressure of 130Mpa on a frame-type cold isostatic press, and the isostatically pressed molding can Form the barren powder into a compact green body;

[0059] 4) Weigh the powder wi...

Embodiment 3

[0072] A preliminary preparation

[0073] 1) Li with a particle size of 100 μm 3 N catalyst powder and hBN content 99% by mass ratio, B 2 o 3 The high-purity hexagonal boron nitride powder with a particle size of 0.3% and a particle size of 30 μm is weighed at a weight ratio of 1:11, put into a mortar and mixed evenly with a spoon to form a mixed powder;

[0074] 2) Put the hand-mixed powder into an inclined, uniformly rotating mixer for mixing; the time is 6 hours; during the mixing process, attention should be paid to the tightness of the sample, in order to avoid Li3N from reacting with water in the air , vacuumize the mixing tank;

[0075] 3), because hBN is a barren raw material, the molding performance is relatively poor; the mixed powder mixed in step 2) is sealed, and isostatically pressed on a frame-type cold isostatic press with a pressure of 140Mpa, and the isostatic molding can Form the barren powder into a compact green body;

[0076] 4) Weigh the powder with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com