Cerium modified calcium-based bifunctional particle, and preparation method and application thereof

A dual-function, calcium-based technology, applied in chemical instruments and methods, other chemical processes, physical/chemical process catalysts, etc., to achieve the effect of increasing adsorption capacity and maximum adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

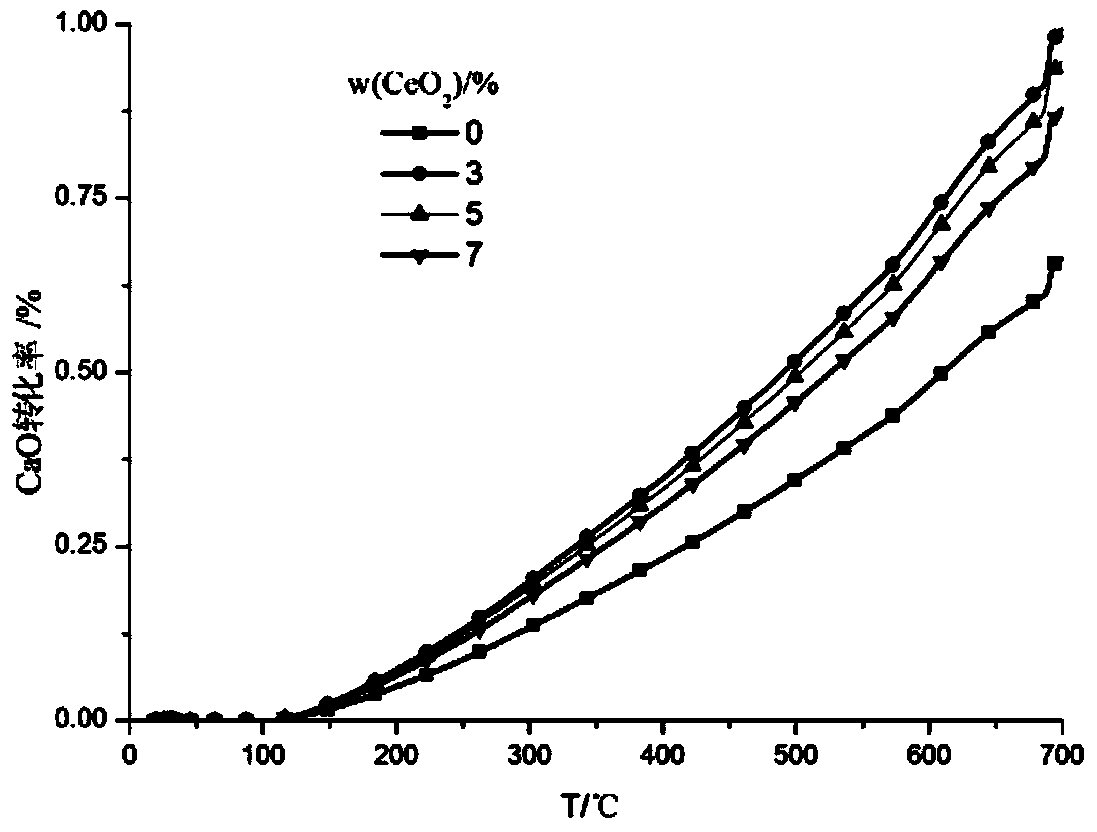

[0056] Implementation example 1: 5%CeO 2 Calcium-based bifunctional particles

[0057] Weigh 9.42g of calcium acetate, 0.3784g of cerium nitrate hexahydrate, 2.2294g of nickel nitrate hexahydrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 80°C, and then calcined at 950°C After 3 hours, it was crushed to obtain 24-65 mesh cerium-modified calcium-based bifunctional particles, and its CeO 2 The mass ratio of Ni to CaO is 0.05:1, and the mass ratio of Ni to CaO is 0.15:1. For the actual preparation, see Figure 5 . In the hydrogen production reaction of adsorption-enhanced ethanol steam reforming, 1.24g of this bifunctional particle is used as a catalyst, and the space velocity of ethanol is 22h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, the reaction temperature is 500°C, the outlet hydrogen concentration is 95%, CO 2 The effective a...

Embodiment 2

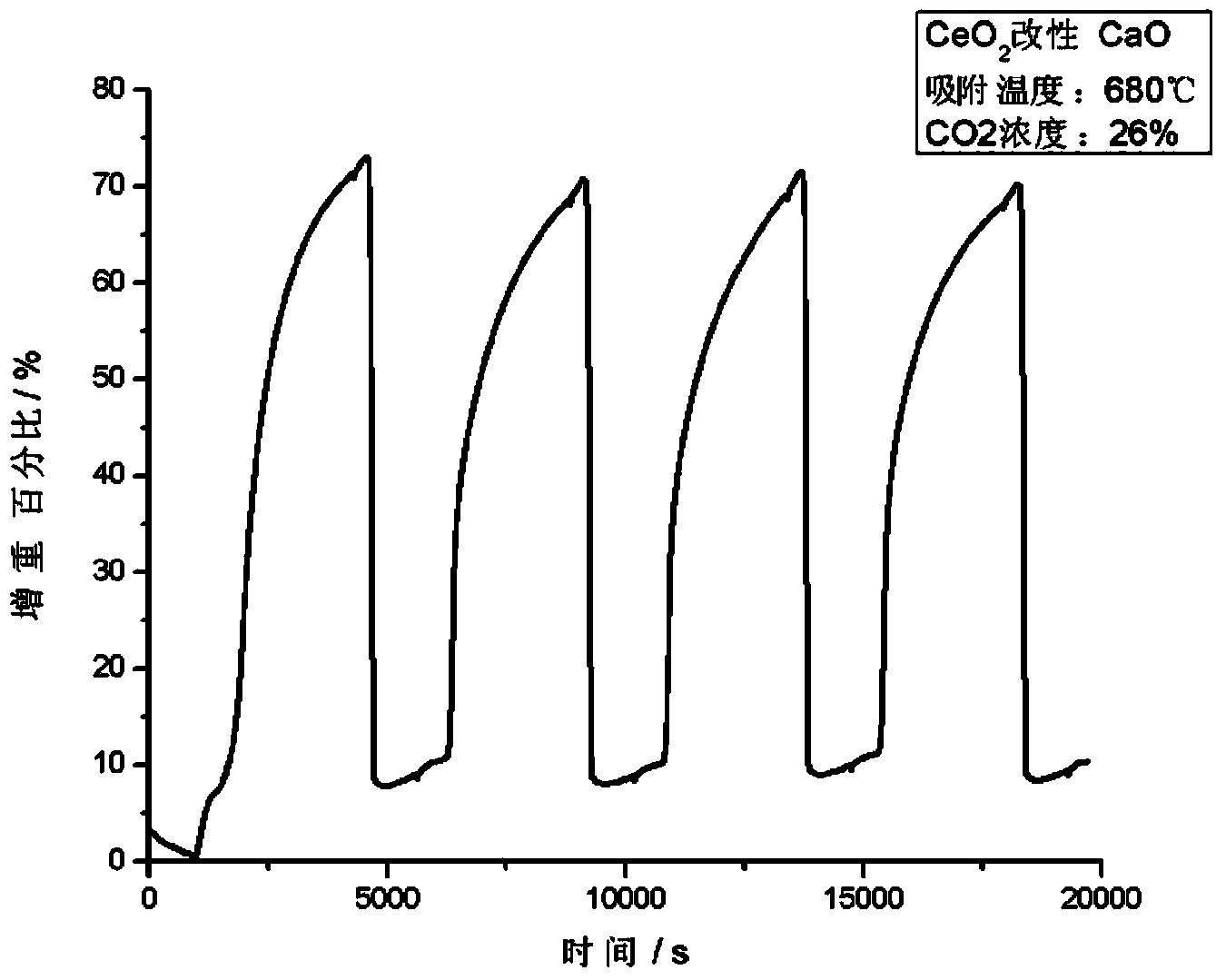

[0058] Implementation example 2: 7%CeO 2 Calcium-based bifunctional particles

[0059] Weigh 9.42g of calcium acetate, 0.5298g of cerium nitrate hexahydrate, 1.4863g of nickel nitrate hexahydrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 80°C, and then calcined at 700°C After 5h, it was crushed to obtain 24-65 mesh cerium-modified calcium-based bifunctional particles, and its CeO 2 The mass ratio of Ni to CaO is 0.07:1, and the mass ratio of Ni to CaO is 0.1:1. In the hydrogen production reaction of adsorption-enhanced ethanol steam reforming, 1.2 g of this bifunctional particle is used as a catalyst, such as figure 2 Shown, the space velocity of ethanol is 22h -1 , the water-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, the reaction temperature is 600°C, the outlet hydrogen concentration is 97%, CO 2 The effective adsorption time is 40min.

Embodiment 3

[0060] Implementation example 3: 3%CeO 2 Calcium-based bifunctional particles

[0061] Weigh 9.42g of calcium acetate, 0.2271g of cerium nitrate hexahydrate, 2.9725g of nickel nitrate hexahydrate and 33.72g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 80°C, and then calcined at 950°C After 3 hours, it was crushed to obtain 24-65 mesh cerium-modified calcium-based bifunctional particles, and its CeO 2 The mass ratio of Ni to CaO is 0.03:1, and the mass ratio of Ni to CaO is 0.2:1. In the adsorption-enhanced ethanol steam reforming hydrogen production reaction, 1.28g of this bifunctional particle is used as a catalyst, and the space velocity of ethanol is 22h -1 , the water-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, the reaction temperature is 500°C, the outlet hydrogen concentration is 96%, CO 2 The effective adsorption time is 50min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com