Hemicyanine fluorescent dye and preparation method and application thereof

A technology for fluorescent dyes and hemicyanine, which is applied in the field of fluorescent dyes, can solve the problems of limited application scope and the like, and achieves the effects of high yield, simple preparation process and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a synthetic method of a semicyanine fluorescent dye with a novel structure, and the specific steps are as follows:

[0024] Dissolve 4.425g (0.025mol) of N,N-diethylbenzaldehyde in 100mL of n-butanol, then add 2.325g (0.025mol) of 4-methylpyridine, and stir the reaction at 100°C for 4 hours. The reaction process was monitored by thin-layer chromatography, and the developing solvent was dichloromethane and petroleum ether (4:1). After the reaction was complete, 2.897 g (0.025 mol) of n-butanol solution of 2-chloroethylamine hydrochloride was added dropwise to the above reaction solution, and the reaction was carried out at a temperature of 75°C for 24 hours. After the reaction, the n-butanol was evaporated with a rotary evaporator, and the final product was precipitated in acetone, filtered, and vacuum-dried to obtain 7.2 g of the product with a yield of 87%.

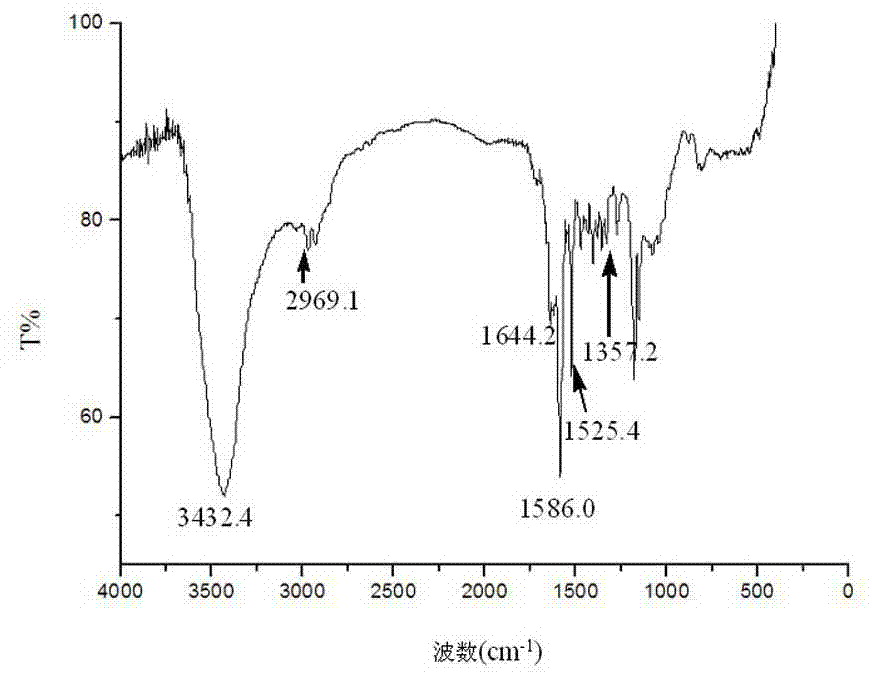

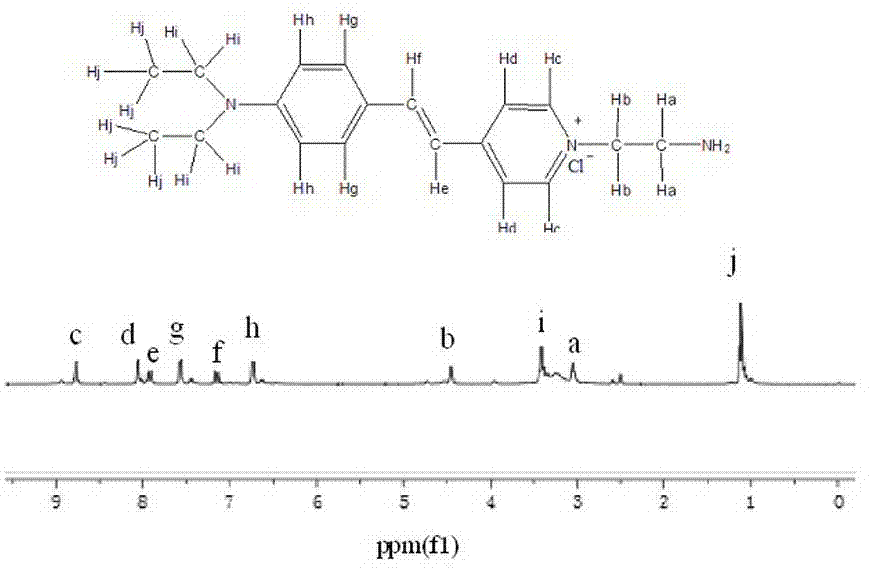

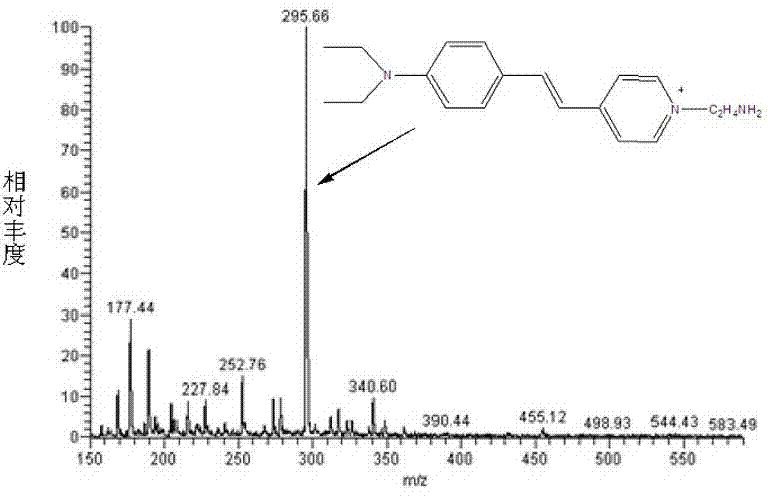

[0025] The product was characterized by infrared spectroscopy, NMR, and mass spectrom...

Embodiment 3

[0034] The half cyanine fluorescent dye provided by Application Example 1 is used to dye silk fabrics, and the cross-linking dyeing process is shown in the attached Figure 8 ;Cross-linking dyeing adopts two-dipping and two-rolling process, the amount of dye is 0.5g / L, the bath ratio is 1:20, the fabric is soaked in the dye solution at room temperature for 3 minutes, and the excess dye solution is removed with a padding car to keep the amount of liquid at 70%. Let dry at room temperature. Soak the fabric in 5% (wt / wt) cross-linking agent DAST for 3 minutes, take it out and use a paddle to remove excess dye solution, keep the amount of liquid at 70%, cross-link in an oven at 60°C for 10 minutes, and finally soap and wash with water ,drying. See attached Figure 7 , It can be seen from the reflectance curve of the dyed silk fabric that the reflectance of the dyed silk fabric is greater than 100% at 600-700 nm, indicating that it has a good fluorescent effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com