NbC particle reinforced iron-based abrasion-resistant laser cladding coating containing rare earth elements and preparation method

A technology of laser cladding and particle enhancement, which is applied in the direction of coating, metal material coating process, etc., to achieve the effect of convenient operation, easy automation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

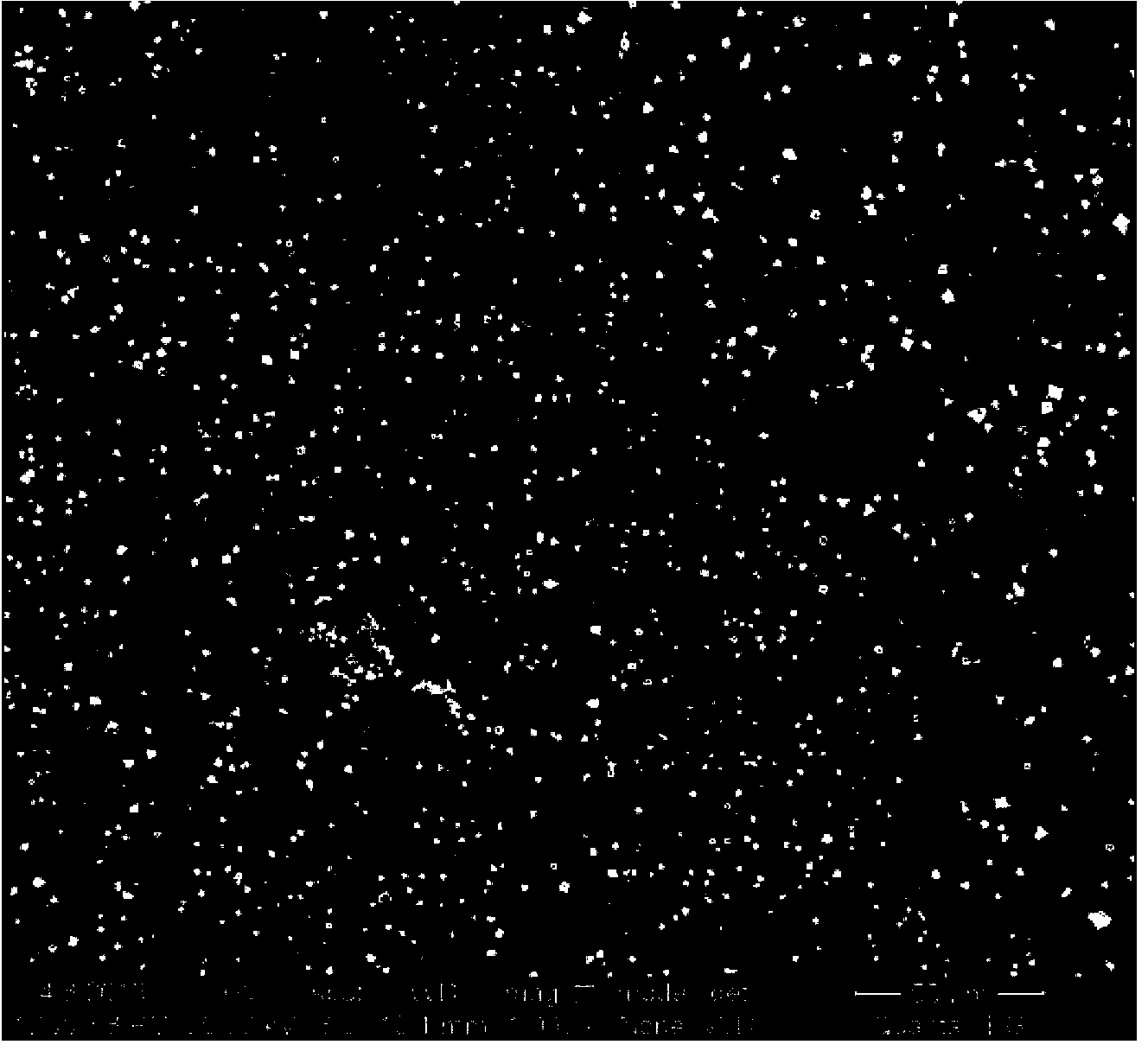

Image

Examples

Embodiment 1

[0028] The coating is prepared under higher power and larger powder feeding rate to obtain a cladding layer with a larger height and width.

[0029] (1) Cr12MoV steel substrate pretreatment

[0030] The surface of the processed automobile die steel Cr12MoV steel substrate is sanded, degreased, and derusted to obtain a smooth and smooth surface.

[0031] (2) Laser cladding

[0032] The composition of the alloy powder used to prepare the coating is:

[0033] Nb: 10wt.%

[0034] Cr: 15wt.%

[0035] B: 1.62wt.%

[0036] Si: 1.5wt.%

[0037] C: 2.5wt.%

[0038] The rest is Fe and unavoidable trace impurities.

[0039] The particle size range of alloy powder is 75-150μm. Add CeO with a particle size range of 35-45 μm to the alloy powder 2 . CeO 2 The addition amount is 4wt.% of the total mass of the cladding alloy powder. After mixing the powder, mix it evenly and dry it for 2 hours. Adjust the laser cladding process parameters, laser power 2000W, scanning speed 4mm / s, ...

Embodiment 2

[0041] The coating is prepared at lower power and smaller powder feeding rate to obtain a cladding layer with smaller height and width.

[0042] (1) Cr12MoV steel substrate pretreatment

[0043] Sand the surface of the processed automobile die steel Cr12MoV steel substrate with sandpaper, degrease and derust to obtain a smooth and smooth surface;

[0044] (2) Laser cladding

[0045] The composition of the alloy powder used to prepare the coating is:

[0046] Nb: 15wt.%

[0047] Cr: 10wt.%

[0048] B: 1.62wt.%

[0049] Si: 1.5wt.%

[0050] C: 4.5wt.%

[0051] The rest is Fe and unavoidable trace impurities.

[0052] The particle size range of alloy powder is 75-150μm. Add CeO with a particle size range of 35-45 μm to the alloy powder 2 . CeO 2 The addition amount is 3wt.% of the total mass of the cladding alloy powder. After mixing the powder, mix it evenly and dry it for 2 hours. Adjust the laser cladding process parameters, laser power 1500W, scanning speed 6mm / s...

Embodiment 3

[0054] Increase the C content in the cladding powder to obtain a high hardness coating.

[0055] (1) Cr12MoV steel substrate pretreatment

[0056] Sand the surface of the processed automobile die steel Cr12MoV steel substrate with sandpaper, degrease and derust to obtain a smooth and smooth surface;

[0057] (2) Laser cladding

[0058] The composition of the alloy powder used to prepare the coating is:

[0059] Nb: 12wt.%

[0060] Cr: 12wt.%

[0061] B: 1.62wt.%

[0062] Si: 1.5wt.%

[0063] C: 5.5wt.%

[0064] The rest is Fe and unavoidable trace impurities.

[0065] The particle size range of alloy powder is 75-150μm. Add CeO with a particle size range of 35-45 μm to the alloy powder 2 . CeO 2 The addition amount is 8wt.% of the total mass of the cladding alloy powder. After mixing the powder, mix it evenly and dry it for 2 hours. Adjust the laser cladding process parameters, laser power 1800W, scanning speed 8mm / s, spot diameter: 5×5mm, powder feeding rate: 12g / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface microhardness | aaaaa | aaaaa |

| Surface microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com