Preparation method for island-actuated single-electron transistor

A single-electron transistor and island-driven technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to reduce difficulty and achieve the effect of precise assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

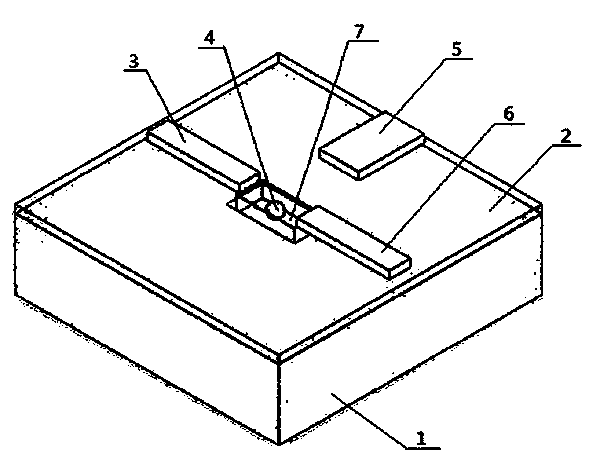

[0030] Island-driven single-electron transistor fabrication:

[0031] (1) cleaning the silicon substrate 1;

[0032] (2) Oxidize the silicon substrate 1 for 2 hours at 1000°C in an oxidation furnace to form a silicon dioxide insulating layer on the surface of the silicon substrate 1 as the substrate 2, and the thickness of the silicon dioxide insulating layer is about 200 nm;

[0033] (3) The source 3, the drain 6 and the gate 5 were prepared on the substrate 2 by electron beam exposure and evaporation coating method. At this time, Ti was used as the metal adhesion layer, and the thickness of the adhesion layer was about 2 nm. Au is used as the deposition material, and the thickness of the deposition material is about 5 nm, wherein the minimum line width of the electrode is about 25 nm, and the distance between the source and the drain on the substrate is about 30 nm; The spacing on the substrate is about 50 nm; and on the substrate 2, the island-moving single Electronic tra...

Embodiment 2

[0045] Island-driven single-electron transistor fabrication:

[0046] (1) cleaning the silicon substrate 1;

[0047] (2) Oxidize the silicon substrate 1 in an oxidation furnace at 1000°C for 2 hours, so that a silicon dioxide insulating layer as the substrate 2 is formed on the surface of the silicon substrate 1, and the thickness of the silicon dioxide insulating layer is about 300 nm;

[0048] (3) The source 3, drain 6 and gate 5 are prepared on the substrate 2 by focused ion beam / electron beam induced deposition. At this time, Pt or W is used as the deposition material, and the thickness of the deposition material is 15-30 nm , wherein the minimum line width of the electrode is about 25 nm, the distance between the source and drain on the substrate is about 30 nm; the distance between the gate and the source and drain on the substrate is about 300 nm; and by Ordinary photolithography or focused ion beam deposition prepares on the substrate 2 micron-scale leads connected to...

Embodiment 3

[0060] Island-driven single-electron transistor fabrication:

[0061] (1) cleaning the silicon substrate 1;

[0062] (2) Oxidize the silicon substrate 1 for 2 hours at 1000°C in an oxidation furnace to form a silicon dioxide insulating layer on the surface of the silicon substrate 1 as the substrate 2, and the thickness of the silicon dioxide insulating layer is about 500 nm;

[0063] (3) The source 3, the drain 6 and the gate 5 were prepared on the substrate 2 by electron beam exposure and evaporation coating method. At this time, Ti was used as the metal adhesion layer, and the thickness of the adhesion layer was about 3 nm. Au is the deposition material, and the thickness of the deposition material is about 25 nm, wherein the minimum line width of the electrode is about 25 nm, and the distance between the source and the drain on the substrate is about 30 nm; The spacing on the substrate is about 500 nm; and the island-moving single Electronic transistor devices transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com