Structure capable of being used for treating heavy metals in bottom mud dredging tail water and construction method thereof

A technology for structures and heavy metals, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the surrounding breeding and river pollution, increase the cost of building grids, and cannot continue normal construction, etc. problems, to achieve the effect of guaranteeing heavy metal pollution, reducing operating costs of wastewater treatment, and easy implementation of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

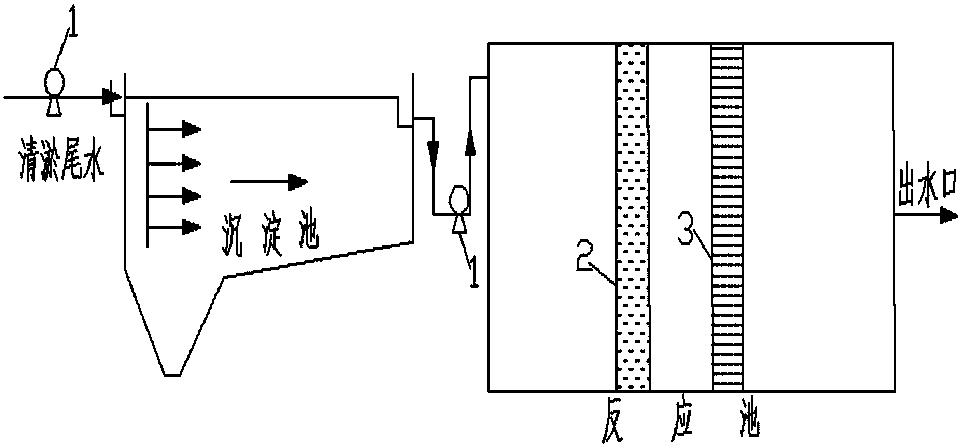

[0030] A heavy metal lead-contaminated site of dredging tail water, according to the pollution range and degree investigation and simulation prediction results of dredging tail water on site, according to the construction method of the present invention, a structure that can be used to process heavy metal pollutants in dredging tail water is made and installed ,Specific steps are as follows:

[0031] (1) Build a sedimentation tank and a reaction tank at the proposed location;

[0032] (2) Excavate two trenches at the planned position of the reaction pool, leaving gaps between the trenches;

[0033] (3) Make grid cages according to the width, depth and thickness of each groove. The circumferential sides of the grid cages are equipped with mesh, and the prepared grid cages are placed on the corresponding In the trench, and make the front and rear sides of the grid cage as vertical as possible to the direction of water flow;

[0034] (4) Fill the groove located at the most upst...

Embodiment 2

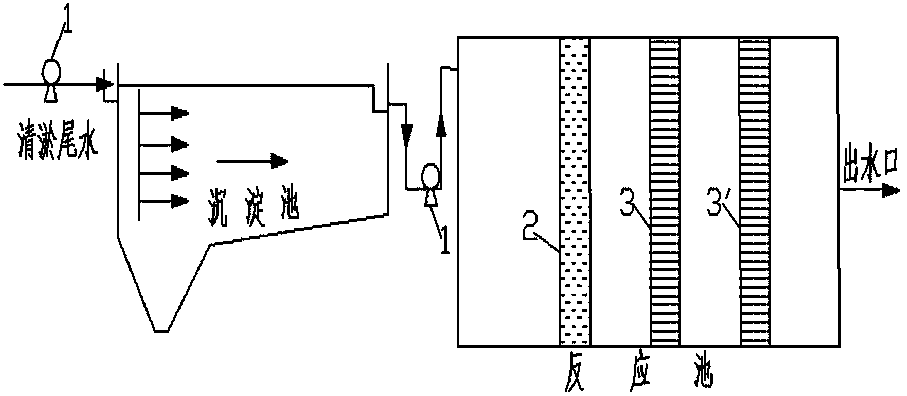

[0043] A heavy metal lead-contaminated site of dredging tail water, according to the pollution range and degree investigation and simulation prediction results of dredging tail water on site, according to the construction method of the present invention, a structure that can be used to process heavy metal pollutants in dredging tail water is made and installed ,Specific steps are as follows:

[0044] (1) Build a sedimentation tank and a reaction tank at the proposed location;

[0045] (2) Excavate three trenches at the planned position of the reaction pool, leaving gaps between the trenches;

[0046] (3) Make grid cages according to the width, depth and thickness of each groove. The circumferential sides of the grid cages are equipped with mesh, and the prepared grid cages are placed on the corresponding In the trench, and make the front and rear sides of the grid cage as vertical as possible to the direction of water flow;

[0047] (4) Fill the groove located at the most up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com