Printing wastewater treatment equipment and process

A technology for printing wastewater and treatment equipment, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. In order to reduce the difficulty of manual operation, improve the biodegradability and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

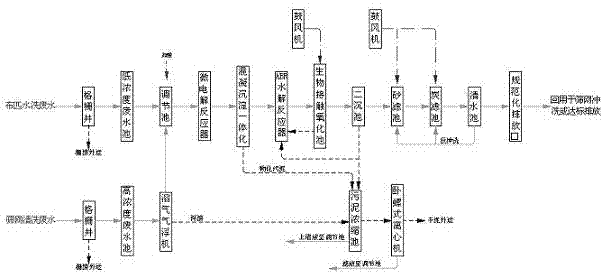

[0039] The printing waste water treatment equipment reference of present embodiment figure 1 , including a regulating tank connected to the wastewater treatment device, and the regulating tank is then sequentially connected with a micro-electrolysis reactor, a coagulation-sedimentation machine, an ABR hydrolysis reactor, a biological contact oxidation tank, a secondary sedimentation tank, a sand filter, Charcoal filter and clean water pool; the waste water treatment device includes a screen waste water pretreatment device and a cloth waste water pretreatment device that adopt shunt treatment; Mesh grid wells, high-concentration wastewater pools and dissolved air flotation machines for net cleaning wastewater; the dissolved air flotation machine outputs the lower clear liquid to the regulating pool connected to it; the cloth wastewater pretreatment device includes The process requires sequentially connected cloth grid wells and low-concentration wastewater pools for receiving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com