A wood vacuum drying and carbonization integrated kiln

A vacuum drying and wood technology, which is applied in drying chambers/containers, partial agitation dryers, dryers for static materials, etc., can solve the problems of large heat consumption and waste of heat, and achieve high work efficiency, reduced fluctuations, and small errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

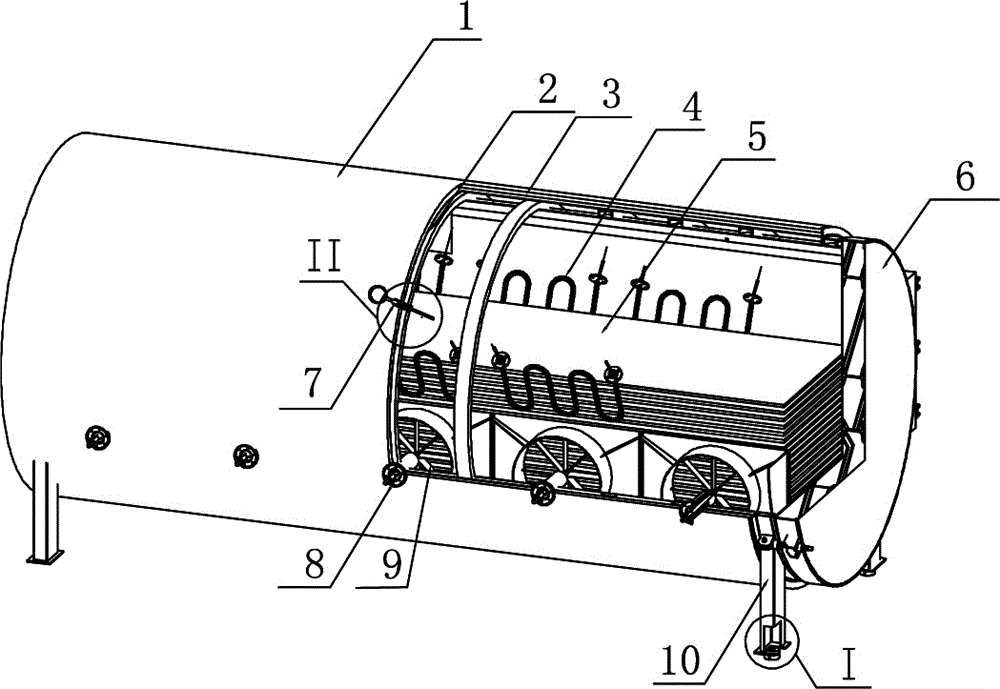

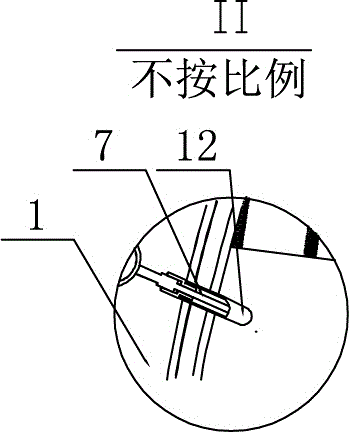

[0013] Such as figure 1 As shown, the wood vacuum drying and carbonization integrated kiln of the present invention includes a kiln body 1 that seals the wood 5 and a vacuum system connected to the kiln body, a steam system, a drainage system, a venting system, a pressurization system and an electric control system. A quick-opening door 6 is provided on the kiln body, and a heating pipe 4 and a convection fan 9 are arranged in the kiln body. The convection fan is connected with the fan drive motor outside the kiln body through a magnetically coupled coupling 8. The kiln body is a sandwich type kiln. The kiln body is covered with thermal insulation material 3, the interlayer of the kiln body is filled with cooling water 2, and the kiln body is provided with a cooling water circulation heat dissipation system.

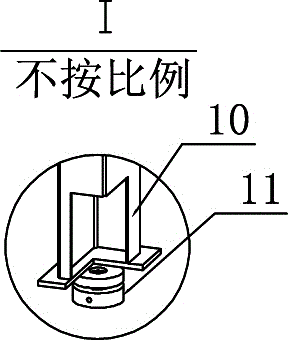

[0014] Such as figure 2 As shown, a foot 10 is provided at the bottom of the kiln body, and the kiln body is suspended from the ground through the foot, and a kiln bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com