Production method of transmissible gastroenteritis virus vaccine

A virus vaccine and production method technology are applied in the production field of porcine transmissible gastroenteritis virus vaccine, which can solve the problems of long time consumption, easy environmental pollution and high production cost, and achieve the reduction of production cost, easy environmental pollution and production cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

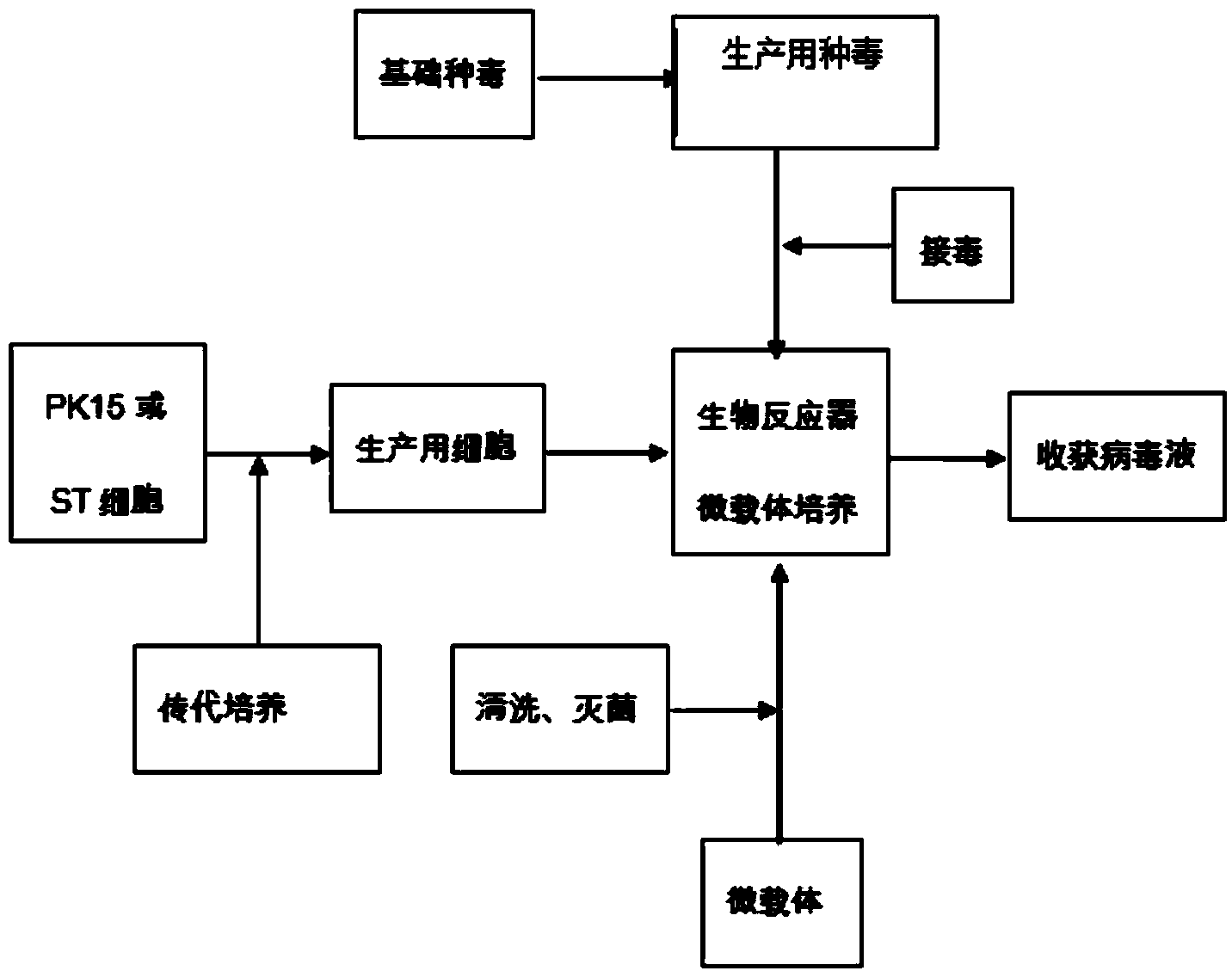

[0027] The production method of porcine transmissible gastroenteritis virus vaccine comprises the following steps:

[0028] Step 1: Subculture and culture of cells for production: take well-grown PK15 or ST cells, pass through EDTA-trypsin cell dispersion (EDTA-trypsin cell dispersion is a specification containing 0.25% mass volume fraction 1:250 trypsin , Hank's solution of 0.02% EDTA; specification 1: 250 trypsin (trypsin containing 250 activity units per gram of trypsin) was digested and passaged, and the solution was digested with 90% DMEM solution, 10% bovine serum, penicillin sodium and Streptomycin sulfate each 200 units / ml, adjust the pH to 7.4 in the cell growth medium and continue to culture at 37°C to form a good monolayer of PK15 or ST cells, which are used for continuous passage or inoculation in bioreactors for microcarriers Suspension culture.

[0029] Step 2: Propagation of seed virus for production: After PK15 cells or ST cells form a monolayer, pour off the ...

Embodiment 2

[0035] The production method of porcine transmissible gastroenteritis virus vaccine comprises the following steps:

[0036] Step 1: Subculture and culture of cells for production: take well-grown PK15 or ST cells, pass through EDTA-trypsin cell dispersion (EDTA-trypsin cell dispersion is a specification containing 0.25% mass volume fraction 1:250 trypsin , Hank's solution of 0.02% EDTA; specification 1: 250 trypsin (trypsin containing 250 activity units per gram of trypsin) was digested and passaged, with 98% DMEM solution, 2% bovine serum, penicillin sodium and Streptomycin sulfate each 200 units / ml, adjust the pH to 7.4 in the cell growth medium and continue to culture at 37°C to form a good monolayer of PK15 or ST cells, which are used for continuous passage or inoculation in bioreactors for microcarriers Suspension culture.

[0037] Step 2: Propagation of seed virus for production: After PK15 cells or ST cells form a monolayer, pour off the cell growth medium, inoculate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com