Attapulgite loaded quasi-one-dimensional titanium dioxide composite photocatalyst and preparation method thereof

A technology of attapulgite and titanium dioxide, which is applied in the field of nanomaterials and photocatalysis, can solve the problems of difficult separation and recovery, difficult dispersion, easy agglomeration, etc., and achieve the effect of recycling and reusing and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

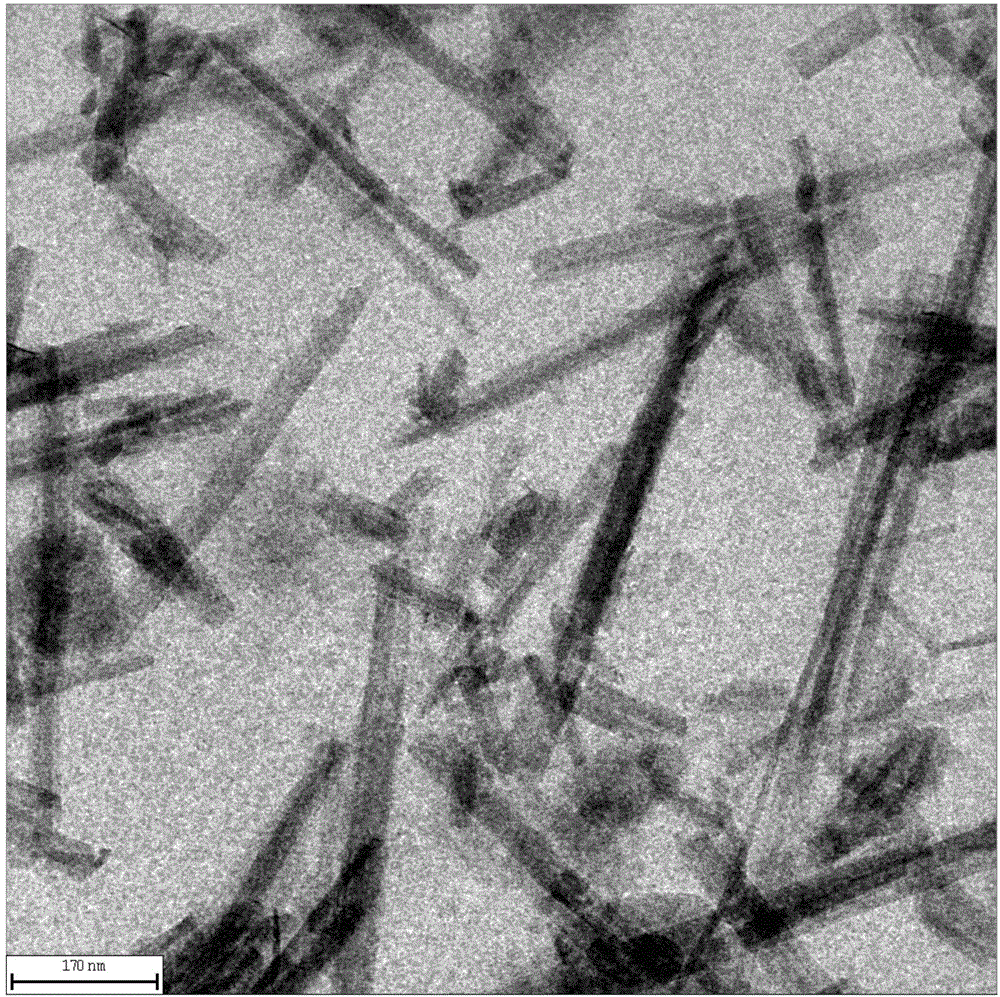

Image

Examples

Embodiment 1

[0034] 1. Prepare 50mL of attapulgite deionized water suspension I with a concentration of 20g / L and uniformly dispersed in a beaker.

[0035] 2. Under the conditions of ice-water bath and 200r / min magnetic stirring, 2.8ml of 98% TiCl 4 Add the solution dropwise to 10ml of sulfuric acid solution with a concentration of 20%, and then add deionized water to prepare 250ml of TiCl with a concentration of 0.1mol / L 4 aqueous solution.

[0036]3. Use 10% dilute sulfuric acid to adjust the pH value of the suspension I in step 1 to 2.5, place the beaker in a constant temperature water bath at 85°C, maintain mechanical stirring at 300r / min, and add 20g of urea as a slow-release agent to obtain Suspension II.

[0037] 4. Immediately add the 0.1mol / L TiCl mentioned in step 2 dropwise at a speed of 1ml / min 4 Aqueous solution enters in the suspension II described in step 3, to TiCl 4 After all the aqueous solution is added dropwise, continue to maintain mechanical stirring at 300r / min i...

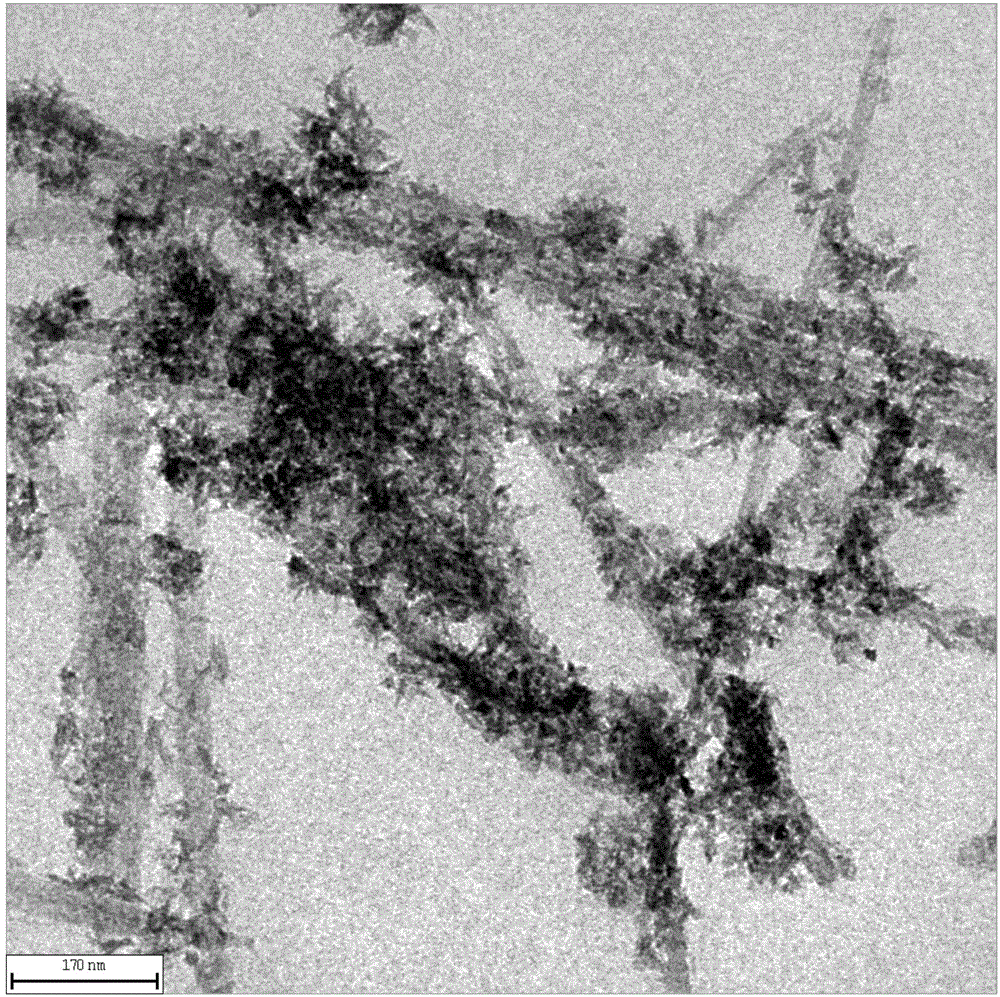

Embodiment 2

[0040] 1. Prepare 50mL of attapulgite deionized water suspension with a concentration of 20g / L and uniformly dispersed attapulgite, add 50mL of concentrated hydrochloric acid (commercial grade product with a concentration of 37.5%) under stirring conditions, let stand for 12 hours, and then centrifuge and collect Solid phase, the obtained solid phase was alternately washed with deionized water and absolute ethanol until the pH value was 3.5, and a uniformly dispersed suspension I with a concentration of 20 g / L was prepared with deionized water.

[0041] 2. Under the conditions of ice-water bath and 200r / min magnetic stirring, 2.8ml of 98% TiCl 4 Add the solution dropwise to 10ml of sulfuric acid solution with a concentration of 20%, and then add deionized water to prepare 250ml of TiCl with a concentration of 0.1mol / L 4 aqueous solution.

[0042] 3. Use 10% dilute sulfuric acid to adjust the pH value of the suspension I in step 1 to 2.5, place the beaker in a constant tempera...

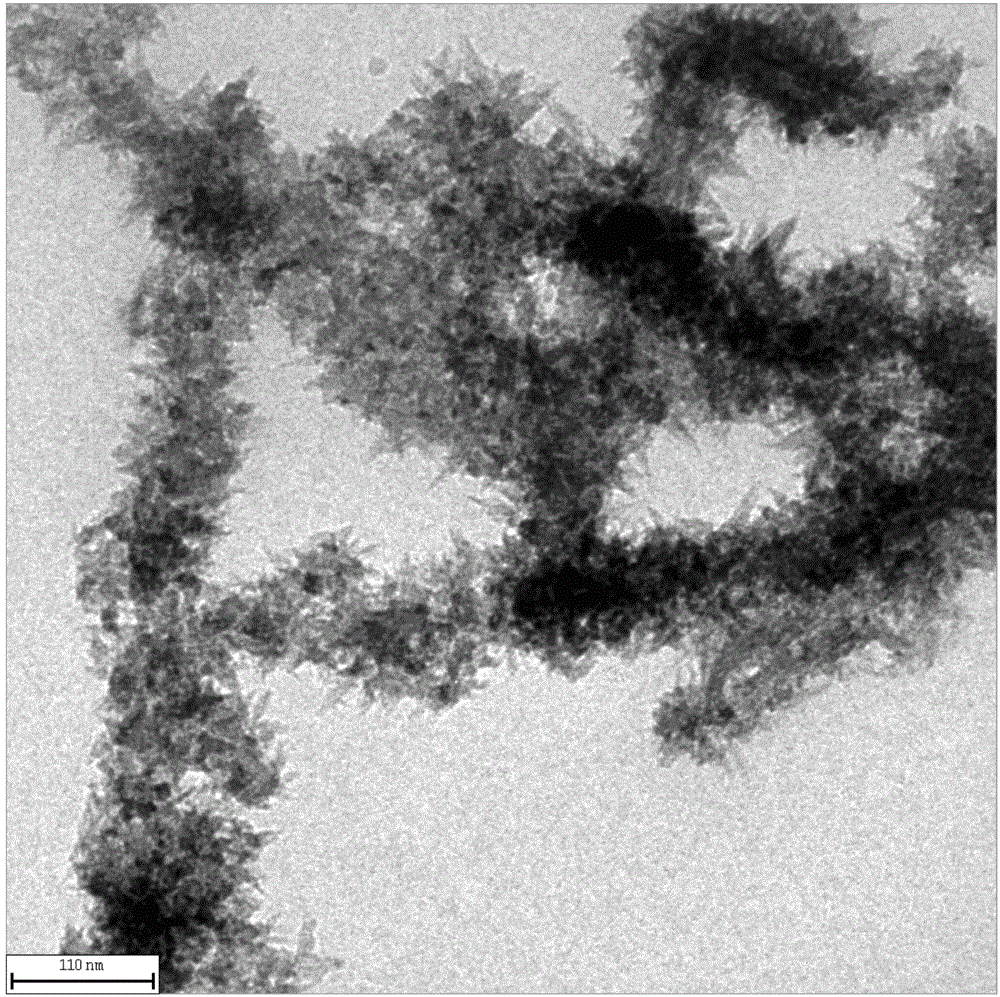

Embodiment 3

[0046] 1. Prepare 50mL of attapulgite deionized water suspension with a concentration of 20g / L and uniformly dispersed attapulgite, add 50mL of concentrated hydrochloric acid (commercial grade product with a concentration of 37.5%) under stirring conditions, let stand for 12 hours, and then centrifuge and collect Solid phase, the obtained solid phase was alternately washed with deionized water and absolute ethanol until the pH value was 4.5, and a uniformly dispersed suspension I with a concentration of 20 g / L was prepared with deionized water.

[0047] 2. Under the conditions of ice-water bath and 200r / min magnetic stirring, 2.8ml of 98% TiCl 4 Add the solution dropwise to 10ml of sulfuric acid solution with a concentration of 20%, and then add deionized water to prepare 250ml of TiCl with a concentration of 0.1mol / L 4 aqueous solution.

[0048] 3. Use 10% dilute sulfuric acid to adjust the pH value of the suspension I in step 1 to 2.5, place the beaker in a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com