A composite matrix self-insulation block and its preparation method

A technology of self-insulating blocks and composite bases, applied in ceramic products, sustainable waste treatment, solid waste management, etc., can solve the problems of inability to reduce material strength and convenient construction performance and indicators, unsatisfactory thermal insulation performance, backward industrial structure, etc. problems, to achieve good thermal insulation performance, lower water absorption, and overall strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

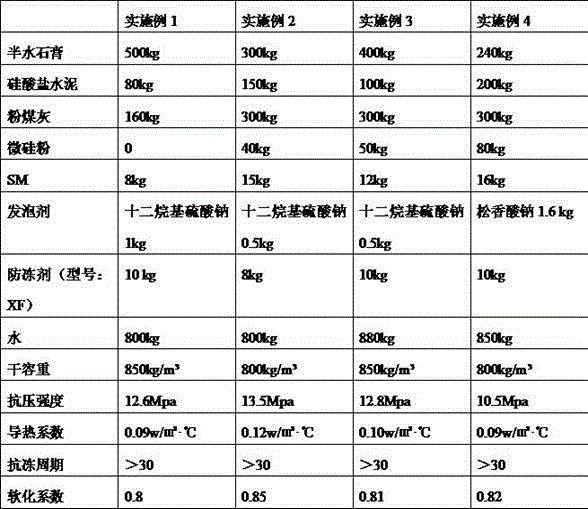

Embodiment 1

[0021] Prepare composite base self-insulation block of the present invention according to the following steps:

[0022] Add 800kg of water into the mixing tank, add 8kg of SM, 1kg of sodium lauryl sulfate, 10kg of commercially available XF antifreeze, and then add 500kg of hemihydrate gypsum, 80kg of ordinary Portland cement and 160kg of fly ash. , high-speed stirring, stirring speed 400-800rpm. The stirring time is 20-30s, and then poured into the mold for molding. Release the mold after about 6-8 minutes of molding hardening. The demoulded blocks are pushed into a low-temperature drying room (at a temperature of about 60-80°C) and dried for 15 hours before being sent to the yard. The blocks after demoulding can also be cured naturally, and the curing time is about 7 days.

[0023] The indicators of the prepared block are: dry bulk density 800kg / m3, compressive strength 12.6Mpa, thermal conductivity 0.09w / ㎡·℃, frost resistance cycle > 30, fire resistance grade A, softening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com