Method of extracting and preparing lysine sulphate from fermenting liquid containing lysin

A lysine sulfate, lysine technology, applied in the preparation of organic compounds, chemical instruments and methods, cyanide reaction preparation and other directions, can solve the problem that the lysine sulfate aqueous solution is not easy to crystallize, the environmental pollution is large, and the process is cumbersome and other problems, to achieve the effect of low cost, low environmental pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

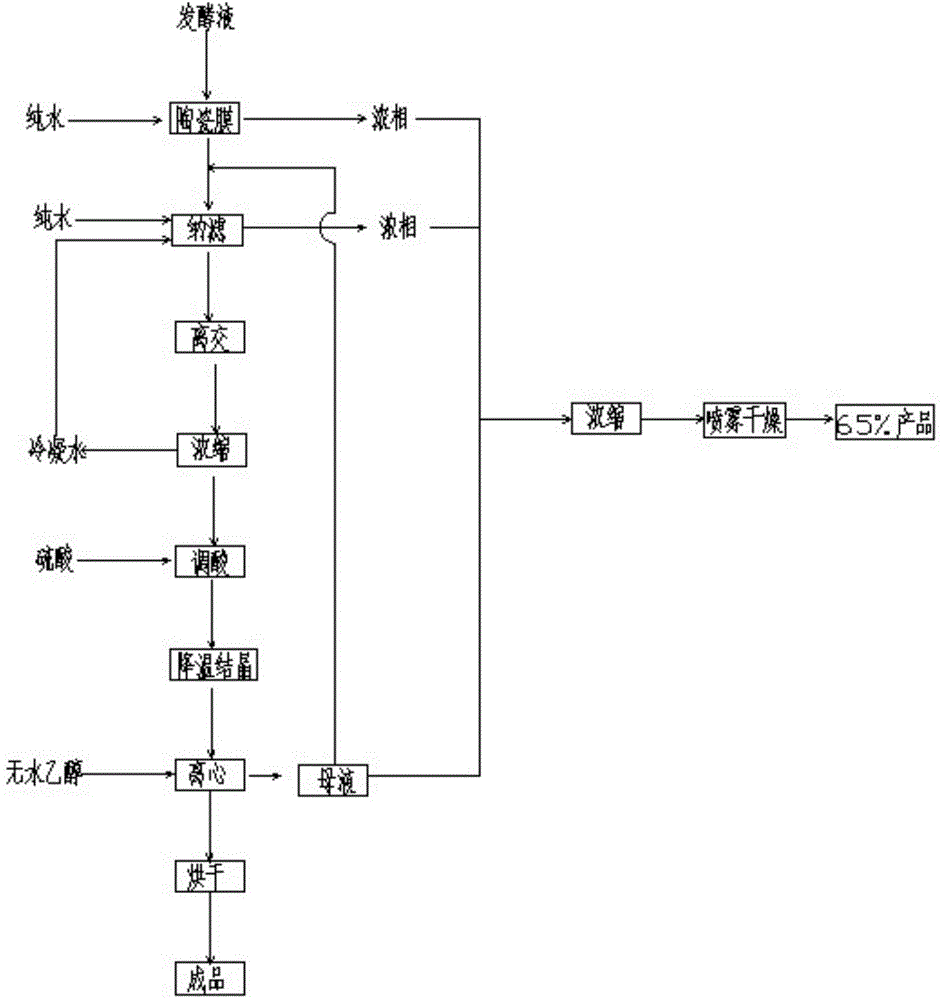

[0031] like figure 1 Shown, the specific steps of the method of the present invention are as follows:

[0032] 1) Take 100L of heated fermentation broth, with a solid content of 25%, a lysine content of 18.5g / 100mL, and a pH value of 6.96.

[0033] 2) The fermentation broth is filtered with a 50nm ceramic membrane to remove bacteria. The inlet pressure of the membrane is 0.2Mpa, the outlet pressure is 0.15Mpa, the flux is 54.4LMH, the concentration is 5.9 times, and the amount of dialysis water is 30L. The dense phase I has a volume of 17L, a lysine content of 4.47g / 100mL, and a solid content of 13.3%.

[0034] 3) Ceramic membrane microfiltrate, solid content 20%, lysine content 15.1g / 100mL. The microfiltrate uses a 500D nanofiltration membrane for decolorization and impurity removal. The inlet pressure of the membrane is 2Mpa, the outlet pressure is 1.8Mpa, the flux is 17.6LMH, and the concentration is 8.8 times. The dense phase II has a volume of 12.5L, a solid content of...

Embodiment 2

[0039] like figure 1 Shown, the specific steps of the method of the present invention are as follows:

[0040] 1) Take 300L of heated fermentation broth, with a solid content of 22.3% (m / m), a lysine content of 16.5g / 100mL, and a pH value of 6.93.

[0041] 2) The fermentation broth is filtered with a 50nm ceramic membrane to remove bacteria. The inlet pressure of the membrane is 0.2Mpa, the outlet pressure is 0.15Mpa, the flux is 46LMH, concentrated to 6 times, and the amount of dialysis water is 100L. Dense phase I has a volume of 50L, a lysine content of 4.9g / 100mL, and a solid content of 15% (m / m).

[0042]3) 150L of ceramic membrane microfiltrate was applied mechanically to 5L of the previous batch of crystallization mother liquor, with a solid content of 16.9% (m / m) and a lysine content of 14.2g / 100mL. The microfiltrate uses a 500D nanofiltration membrane for decolorization and impurity removal. The inlet pressure of the membrane is 2Mpa, the outlet pressure is 1.8Mpa, ...

Embodiment 3

[0049] like figure 1 Shown, the specific steps of the method of the present invention are as follows:

[0050] 1) Take 500L of heated fermentation broth, with a solid content of 23.5% (m / m), a lysine content of 18.5g / 100mL, and a pH value of 6.97.

[0051] 2) The fermentation broth is filtered with a 50nm ceramic membrane to remove bacteria. The inlet pressure of the membrane is 0.2Mpa, the outlet pressure is 0.15Mpa, the flux is 65LMH, the concentration is 6 times, and the amount of dialysis water is 175L. The dense phase I has a volume of 83L, a lysine content of 4.1g / 100mL, and a solid content of 14.6% (m / m).

[0052] 3) 300L of ceramic membrane microfiltrate was applied to 10L of crystallization mother liquor from the previous batch, with a solid content of 17.5% (m / m) and a lysine content of 14.8g / 100mL. The microfiltrate uses a 500D nanofiltration membrane for decolorization and impurity removal. The inlet pressure of the membrane is 2Mpa, the outlet pressure is 1.8Mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com