Method for synthesizing resinous vitamin D3 by using micro-flow photoreaction technology and micro-flow photochemical reactor

A technology of chemical reactor and photochemical reaction, which is applied in the field of organic photochemical synthesis, can solve the problems of cumbersome processing process and complex structure of reaction device, and achieve the effect of simple and easy operation of the preparation process and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

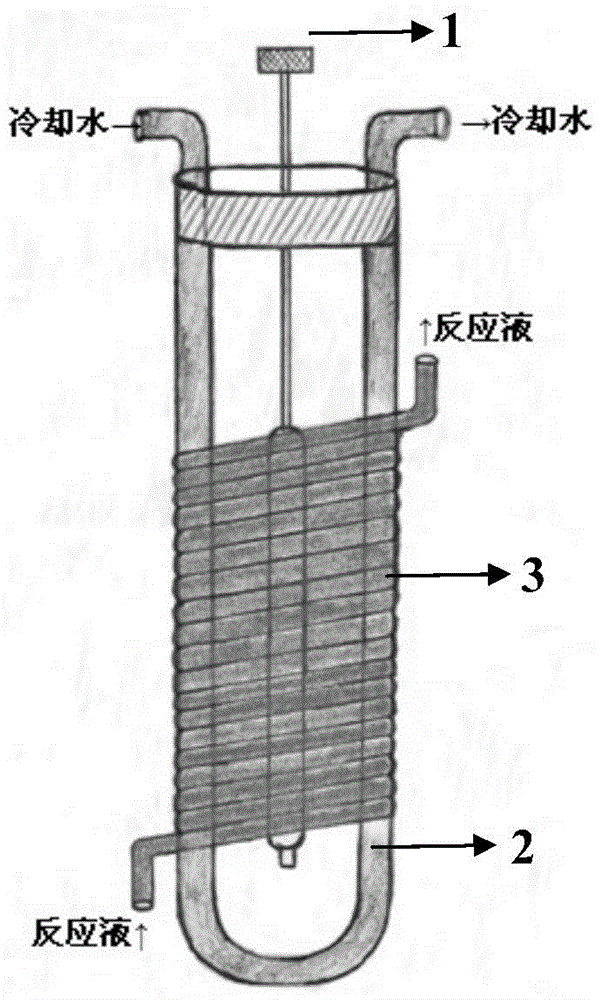

[0031] Such as figure 1 shown, for the synthesis of resinous vitamin D 3The microfluidic photochemical reactor consists of a light source 1, a cold trap 2 and a microfluidic tube 3.

[0032] The cold trap 2 is a U-shaped interlayer container with a cooling water inlet and outlet made of quartz or borosilicate glass, and the micro-pipe made of quartz or borosilicate glass is the micro-flow tube 3 and A 450W high-pressure mercury lamp (such as GGZ1000-1 from Beijing Electric Light Source Research Institute) wrapped around the outer wall of the cold trap and placed in the inner cavity of the cold trap at the place where the microfluid tube is wound is the light source 1 .

[0033] The micro-flow tube is a micro-pipe with an inner diameter of 2mm and a length of 8-10m, which can filter out light with a wavelength shorter than 305nm.

[0034] Synthesis of resinous vitamin D using the microfluidic photochemical reactor described above 3

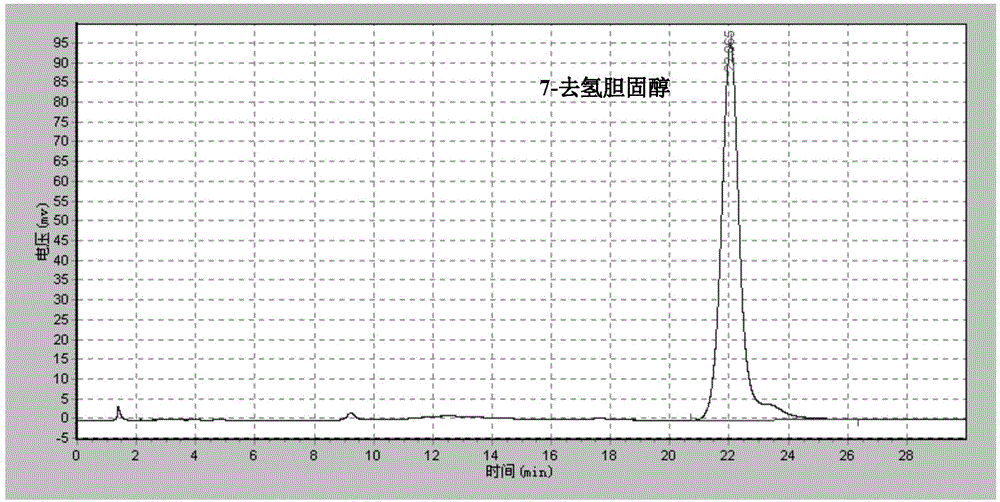

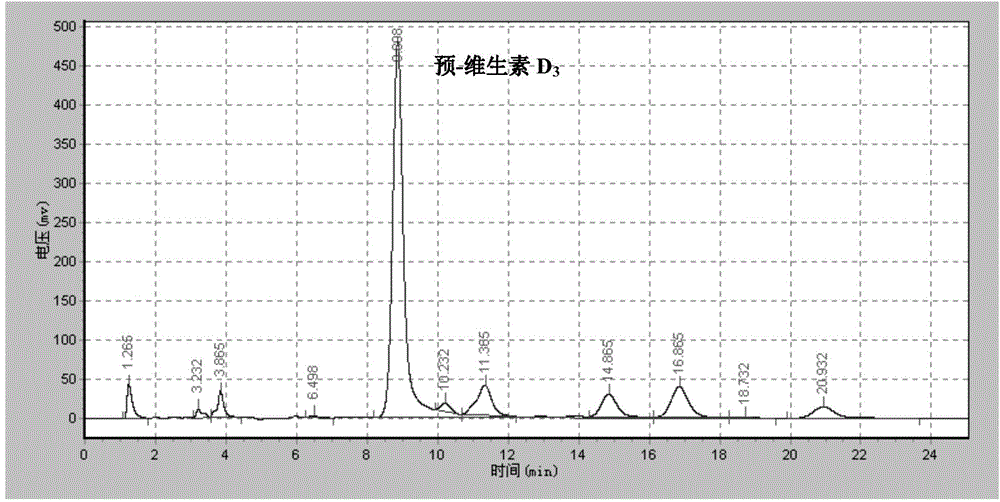

[0035] (1) Photoisomerization of 7-dehy...

Embodiment 2

[0042] Utilize the microflow photochemical reactor of embodiment 1 to carry out synthetic resinous vitamin D 3

[0043] (1) Photoreaction of 7-dehydrocholesterol

[0044] In a 500mL round bottom flask, under nitrogen protection, 16.5g of 7-dehydrocholesterol was dissolved in 275mL of pentane-methanol (10:1, V / V) mixed solvent, and 33mg of 2,6-di-tert-butyl -P-methoxyphenol, mixed evenly with magnetic stirring, is prepared into a photochemical reaction solution; after passing nitrogen in the photochemical reaction solution for 30 minutes, turn on condensed water, a 450W high-pressure mercury lamp, and a peristaltic pump in turn, and pass through the peristaltic pump. The photochemical reaction solution was continuously injected into the microflow tube of the microflow photochemical reactor at a speed of 4.5mL / min to carry out the light reaction until the prepared photochemical reaction solution flowed out. During the light reaction, the temperature of the photoreaction solutio...

Embodiment 3

[0049] In a 500mL round bottom flask, under nitrogen protection, dissolve 16.5g of 7-dehydrocholesterol in 330mL of hexane-dioxane (5:1, V / V) mixed solvent, add 15mg of 2,6-di-tert-butyl base-p-methoxyphenol, mixed evenly with magnetic stirring, and prepared into a photochemical reaction solution; after passing nitrogen gas into the photochemical reaction solution for 30 minutes, turn on condensed water, a 450W high-pressure mercury lamp, and a peristaltic pump in turn, and pass through the peristaltic pump. The photochemical reaction solution was continuously injected into the microflow tube of the microflow photochemical reactor at a speed of 6 mL / min to carry out the light reaction until the prepared photochemical reaction solution flowed out. During the light reaction process, the temperature of the photoreaction solution was controlled to be 23~28℃; use conical flask to receive the precursor pre-vitamin D flowing out from the outlet of micro-flow tube after light reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com