Aqueous double-component inner wall heat-insulation coating

A thermal insulation coating, a two-component technology, applied in the field of coatings and paints, can solve the problems of heat loss, high building energy consumption, uneven heat consumption of neighbors, etc., to block heat loss, improve thermal insulation effect, and improve thermal comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

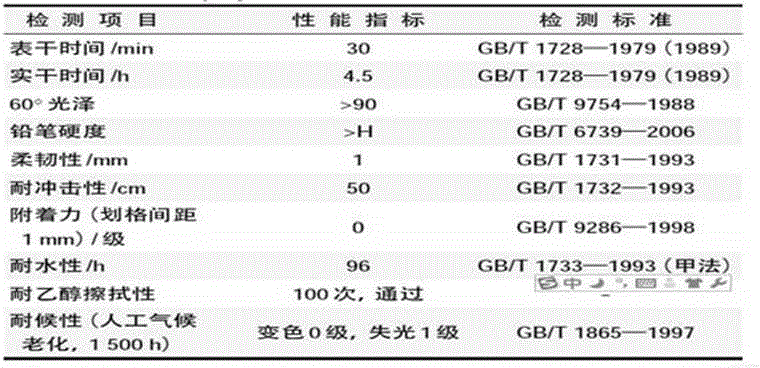

Examples

Embodiment 1

[0029] The coating is made up of component A and component B. The formula of component A is as follows:

[0030] 20-25 parts of styrene-acrylic emulsion

[0031] 20-25 parts of phenolic resin

[0032] 5~10 parts of dispersant

[0033] Mixture of ethylene glycol and glycerol 6~8 parts

[0034] 10-20 parts of filler

[0035] 5-10 parts of infrared reflective pigment, doped semiconductor and metal powder with a refractive index above 2.0 and a particle size of not less than 1μm.

[0036] Auxiliary 5-10 parts

[0037] 20-25 parts of water

[0038] Antifreeze 1-2 parts

[0039] 6-10 parts of B-component polyisocyanate curing agent,

[0040] Add component A to the container according to the above formula, add deionized water, fillers, and additives in sequence under medium-speed stirring, disperse at high speed for 20-30 minutes, add water-dispersible polyisocyanate curing agent in a certain proportion, and stir thoroughly , To prepare water-based two-component interior wall insulation coating.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com