Heating system for separating harmful substances in oil

A heating system and technology of harmful substances, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of reducing heat exchange efficiency, not meeting production requirements, weak circulation, etc., to improve the utilization rate of heat energy, avoid heat loss, avoid fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

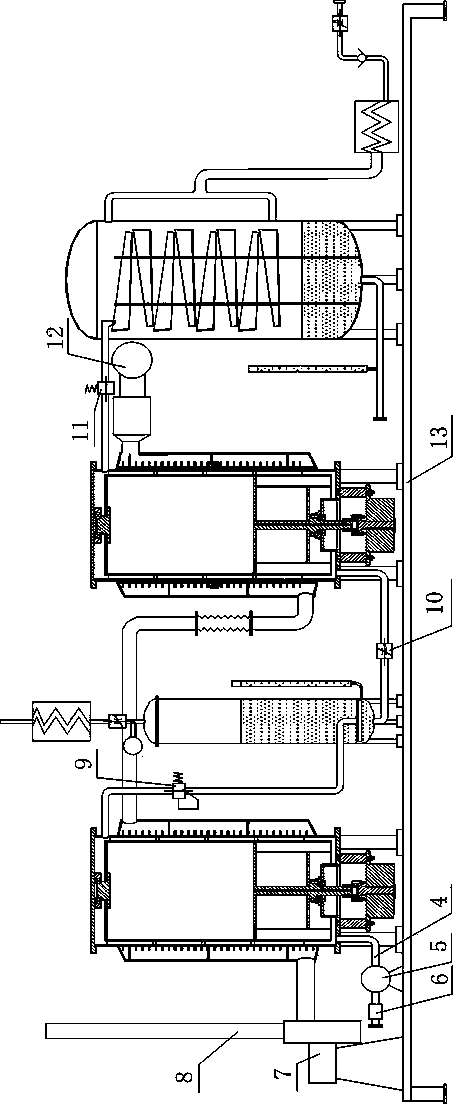

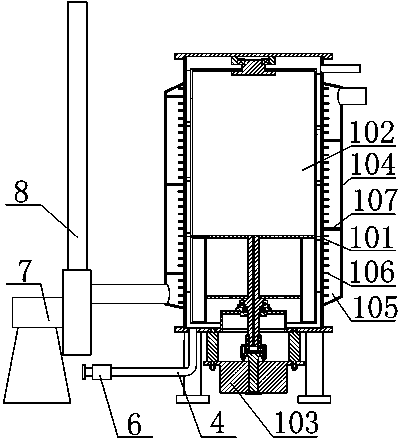

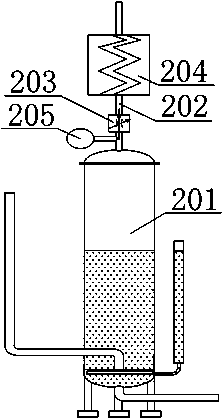

[0028] Such as Figure 1~5 As shown, the heating system used to separate harmful substances in grease includes a primary heating system, a gas-liquid separation tank, a secondary heating system, and a smoke scattering system that are connected in sequence. Among them, the primary heating system, the gas-liquid separation tank, and the secondary The heating system and the smoke dispersing system are both arranged on the supporting table 13, and the entire system is assembled in a cabinet. Both the primary heating system and the secondary heating system include a heating pot body 101, a rotating drum 102 arranged in the heating pot body 101, a deceleration mechanism 103 passing through the bottom of the heating pot body 101 and connected to the rotating drum 102, and a deceleration mechanism 103 Connected to the driving device, the side wall of the rotating drum 102 is provided with scrapers arranged in the vertical direction and in contact with the inner side wall of the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com