Liquid-state fermentation production method of cellulase

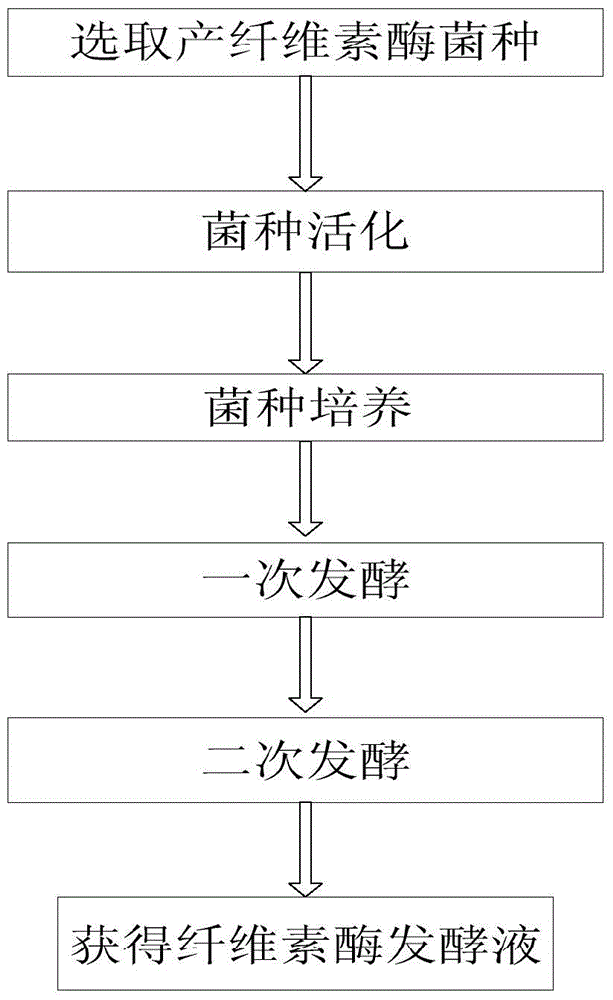

A cellulase and production method technology, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve problems such as difficult large-scale industrial production, easy contamination of miscellaneous bacteria, and difficult extraction, and improve product quality. , The effect of shortening fermentation time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Cellulase activity assay

[0026] The enzyme activity involved in the present invention is determined as filter paper enzyme activity.

[0027] The various enzyme activities involved in the present invention are agreed to be defined as: under the condition of 50±0.1°C and pH4.8, 1ml of enzyme solution hydrolyzes the substrate for 1min to produce the amount of reducing sugar equivalent to 1 μmol of glucose, which is 1 enzyme activity unit. Expressed in IU / ml.

[0028] The enzyme activity detection methods are all carried out according to the international method IUPAC.

[0029] Determination method of filter paper enzyme activity: 1ml of crude enzyme solution, under the conditions of 50±0.1°C and pH4.8, the amount of reducing sugar produced by hydrolyzing 50±1mg of filter paper for 1 hour, and the amount of reducing sugar produced was determined by DNS method.

Embodiment 2

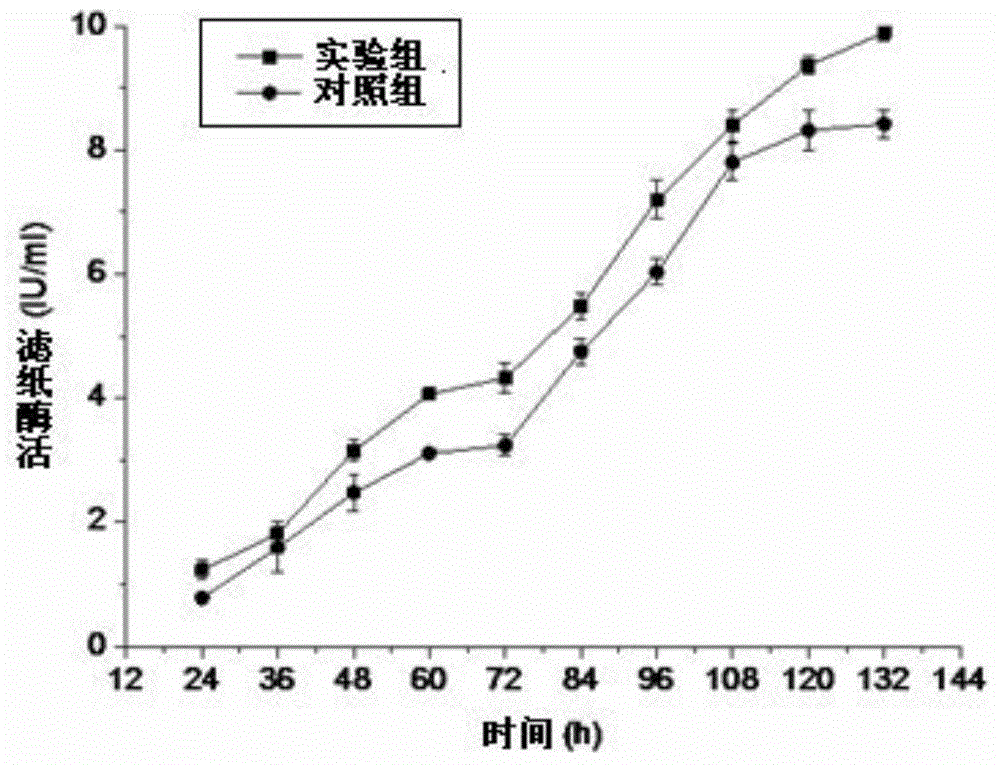

[0031] 1) Experimental group: cellulase liquid state fermentation method of the present invention

[0032] Strain activation: Among the cellulase-producing bacteria, representative Trichoderma reesei RUT-C30 and Penicillium juniperi 9-3 were selected as the production bacteria for cellulase liquid fermentation. Store at 4°C for later use;

[0033] Bacteria culture: Wash the slant spores with sterile water, and adjust the spore concentration to 10 on the hemocytometer 7 Individual / ml, inoculate the seed culture medium according to the volume ratio of the inoculation amount of 3:100, and cultivate the strain seed liquid at 28°C for 18-24h;

[0034] Primary fermentation: (1) inoculate the fermentation medium with the seed solution of Penicillium and Trichoderma according to the volume ratio of 1:20, ferment Penicillium at 30°C for 120h, and ferment Trichoderma at 26°C 120h, obtain Penicillium primary fermentation liquid and Trichoderma primary fermentation liquid respectively, ...

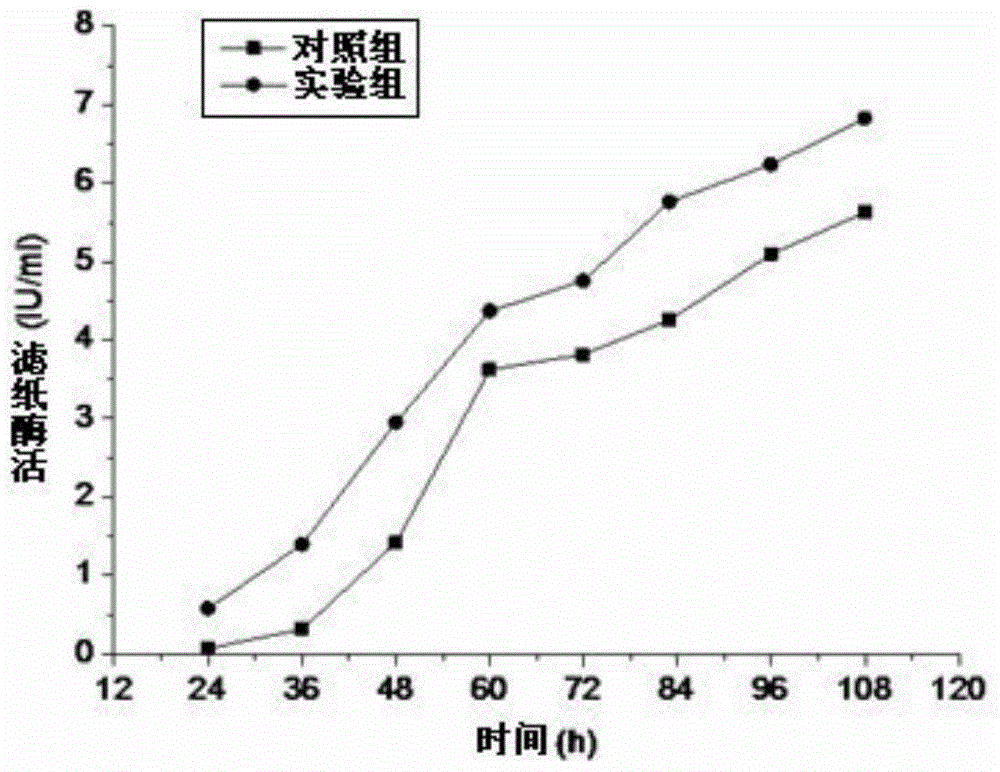

Embodiment 3

[0043] Strain activation: Among the cellulase-producing bacteria, select the representative Trichoderma reesei RUT-C30 as the production strain. After passage and activation, store it on a PDA slope at 4°C for later use;

[0044] Bacteria culture: Wash the slant spores with sterile water, and adjust the spore concentration to 10 on the hemocytometer 7 Each / ml, inoculate the seed medium according to the volume ratio of 3:100, and cultivate at 28°C for 18-24h;

[0045] Primary fermentation: Inoculate the cultured strain Trichoderma reesei into the fermentation medium according to the volume ratio of 1:20, ferment for 120 hours at 26°C, centrifuge at 1200 rpm for 5 minutes to obtain a primary fermentation liquid, and centrifuge the primary fermentation liquid Filter through 0.22 μm, 0.45 μm and 0.8 μm filter membranes to remove impurities (residual hyphae, spores, etc.) The fermented liquid that was filtered and only centrifuged was used as a control. The results showed that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com