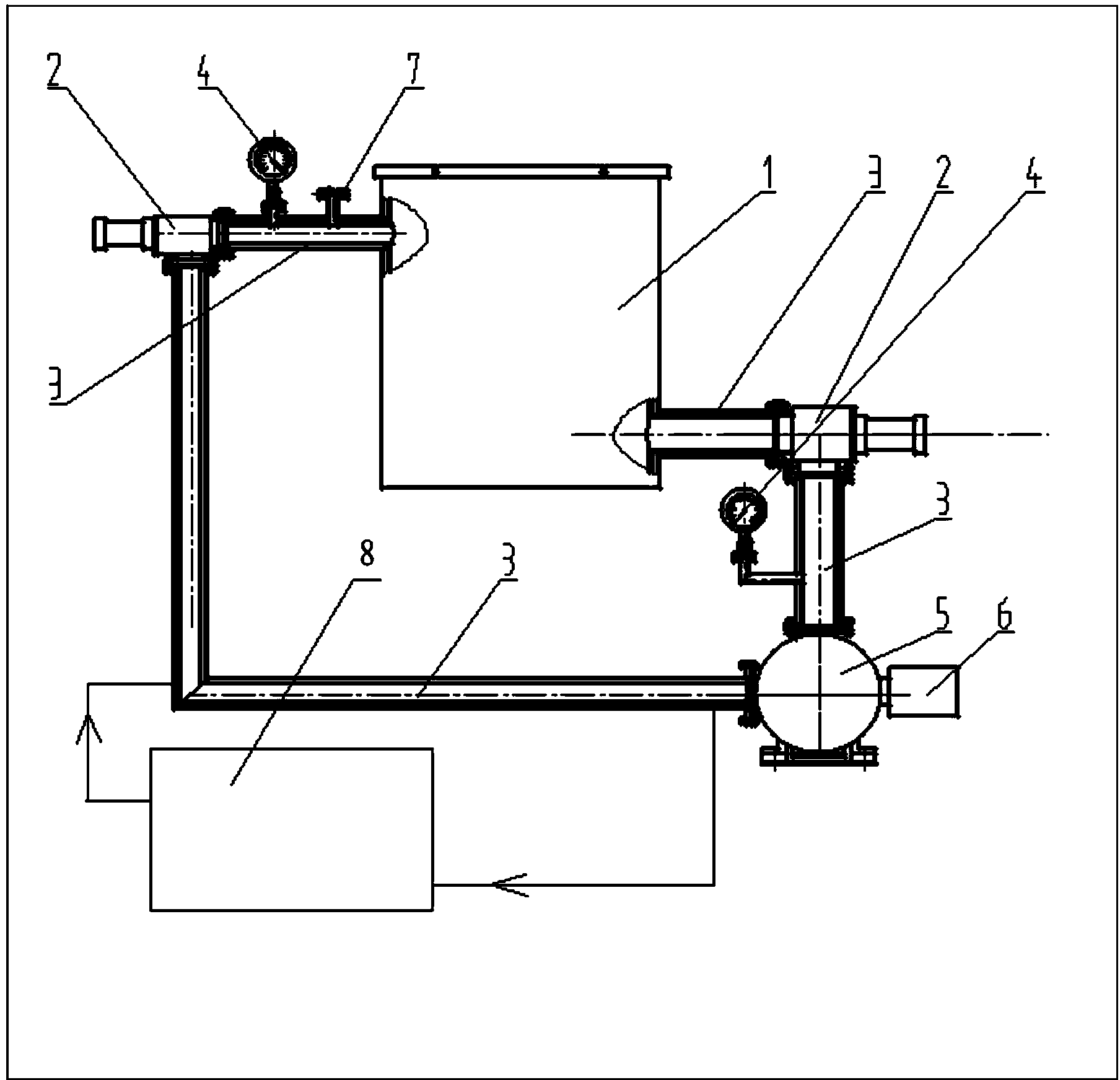

Rapid circulation air cooling vacuum furnace

A rapid cycle, vacuum furnace technology, used in furnaces, furnace cooling, furnace components, etc., can solve problems affecting processing quality, furnace cavity size and process limitations, waste of inert gas, etc., to achieve a wide annealing process range and wide use conditions , Air cooling effect uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

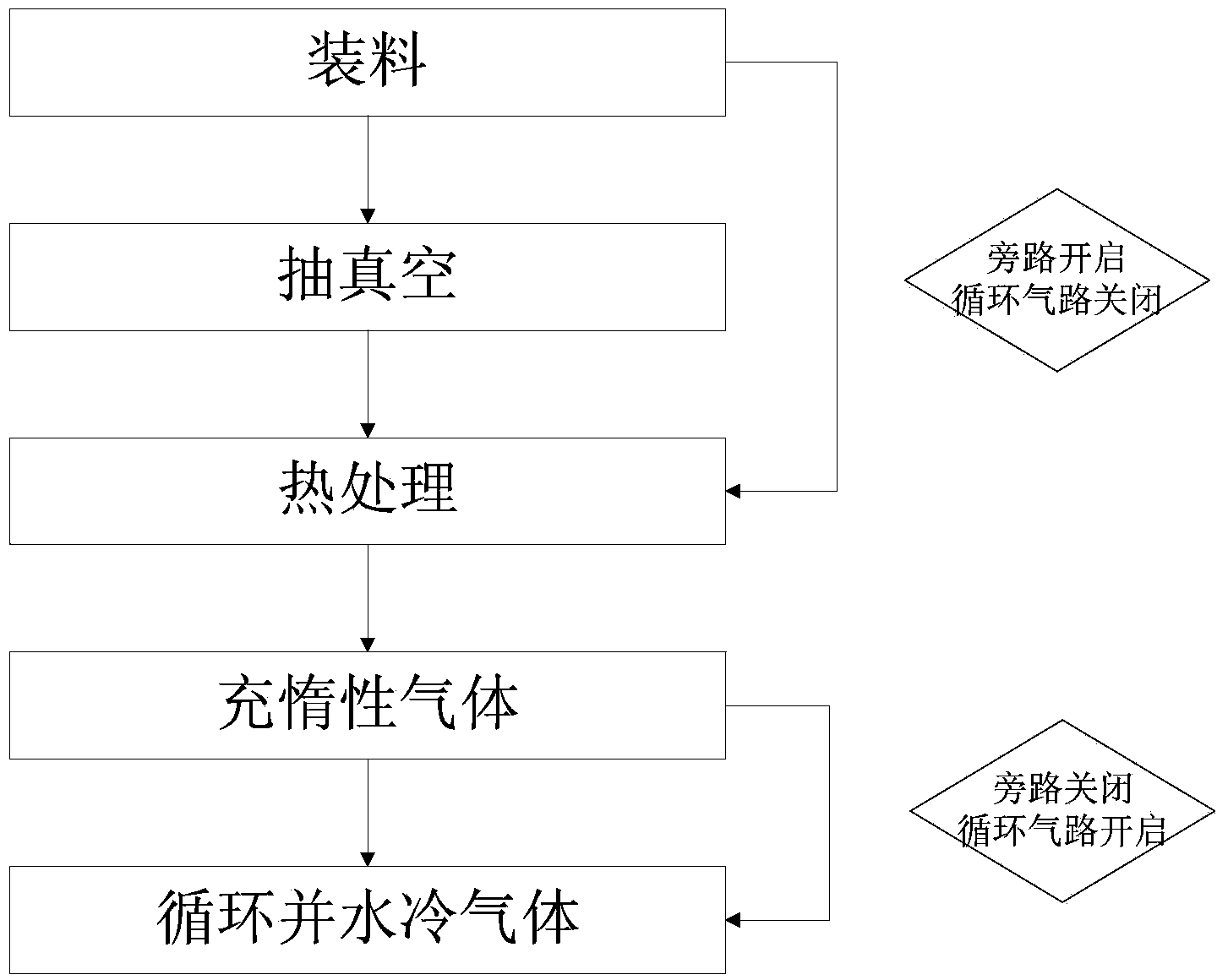

Method used

Image

Examples

Embodiment 1

[0039] After the CVD diamond is annealed from 1100°C to 500°C in a fast-circulating air-cooled vacuum furnace, the bypass is closed, and a hydrogen-argon gas mixture is introduced until the chamber pressure is 3.0KPa. Turn on the rapid cycle air cooling system and turn on the water cooling device. Adjust the frequency conversion motor and water cooling device to make the system reduce the temperature of CVD diamond from 500°C to below 100°C within 15 minutes.

Embodiment 2

[0041] After the tungsten carbide powder compact is sintered at 1400°C in a fast-circulating air-cooled vacuum furnace, the bypass is closed and hydrogen gas is introduced until the chamber pressure is 0.5KPa. Turn on the rapid cycle air cooling system and turn on the water cooling device. Adjust the frequency conversion motor and water cooling device to make the system reduce the temperature of the cemented carbide blank from 1400°C to 700°C within 2 hours. Continue to feed hydrogen until the chamber pressure is 2KPa, adjust the frequency conversion motor and water cooling device, and the system will reduce the temperature of the cemented carbide blank from 700°C to below 100°C within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com