A flavor-improved almond milk and its preparation method

An almond and flavor technology is applied in the field of flavor-improved almond dew and its production to achieve the effects of stable blood sugar response, eliminating wound stasis and improving umami taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of almond slurry: Select sweet almonds with good appearance, soak them in warm water at 42-48°C for 5-6 hours, peel them, rinse the peeled almonds, mix them with water according to the weight-to-liquid ratio of 1:10, and then place Grind in a refiner for 10-15 minutes, then filter to get the filtrate;

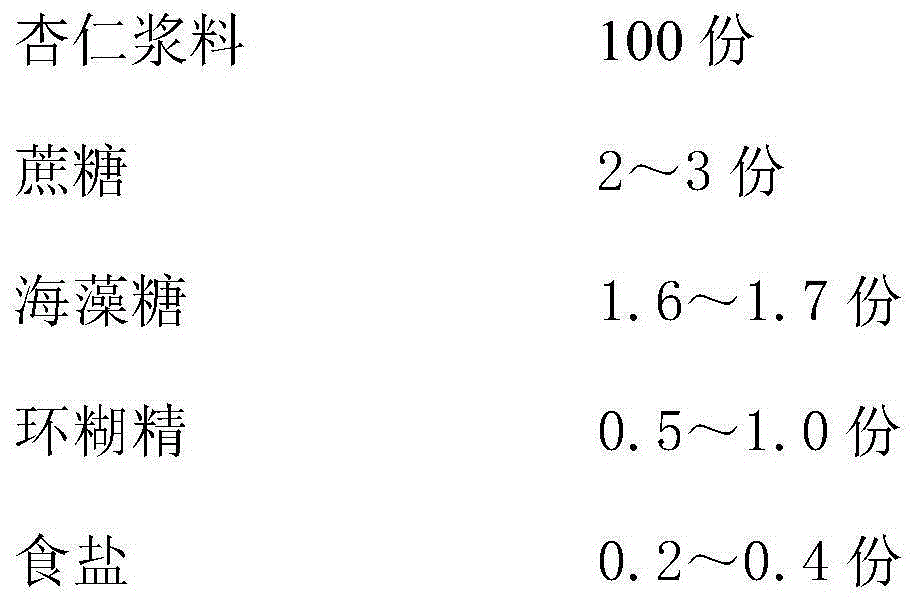

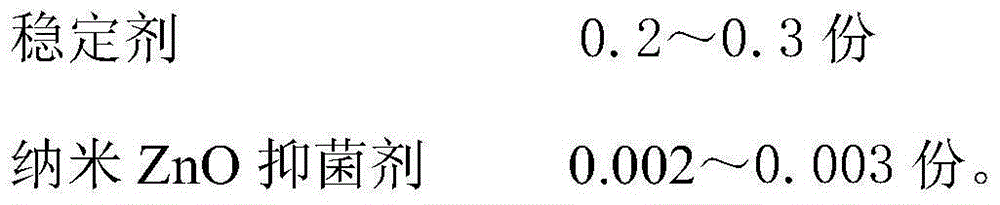

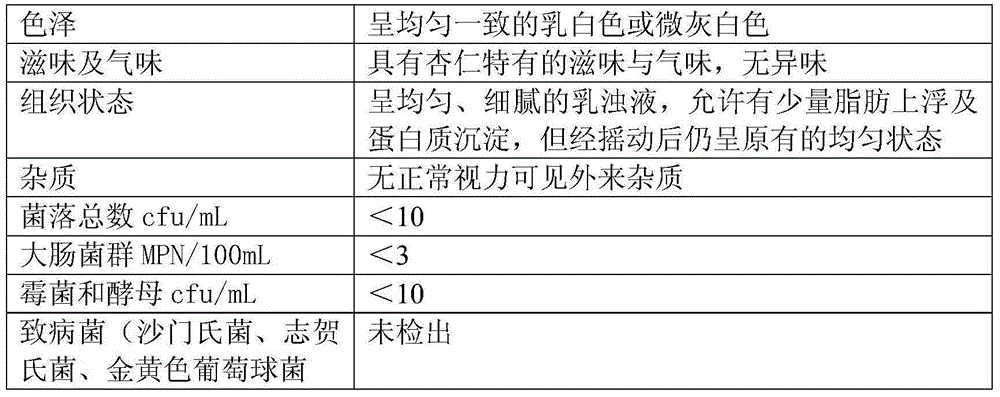

[0034] Weigh 100 parts of prepared almond slurry, add 2 parts of sucrose, 1.6 parts of trehalose, 0.5 part of cyclodextrin, 0.2 part of salt and 0.2 part of stabilizer, stir and mix, boil the mixed slurry and cool down to 78 At ℃, carry out two-stage homogeneous reflux three times respectively, wherein the pressure of the first-stage homogeneous is 43Mpa, and the pressure of the second-stage homogeneous is 15Mpa, and the homogeneous slurry is filled into a tank while it is hot, and after degassing, press 0.02g / kg almond Add nano-ZnO antibacterial agent, cover and seal, and then sterilize in an autoclave. The sterilization formula used is 10ˊ-15ˊ-5ˊ / 100°C, and...

Embodiment 2

[0038] Preparation of almond slurry: Select sweet almonds with good appearance, soak them in warm water at 42-48°C for 5-6 hours, peel them, rinse the peeled almonds, mix them with water according to the weight-to-liquid ratio of 1:10, and then add Mix 0.5wt% of the ultra-finely pulverized rose powder in the slurry, then place it in a refiner and grind it for 10 to 15 minutes, and filter to get the filtrate;

[0039] Weigh 100 parts of prepared almond slurry, add 3 parts of sucrose, 1.7 parts of trehalose, 1.0 part of cyclodextrin, 0.4 part of salt and 0.3 part of stabilizer, stir and mix, boil the mixed slurry and cool down to 82 At ℃, carry out two-stage homogeneous reflux three times respectively, wherein the pressure of the first-stage homogeneous is 48Mpa, and the pressure of the second-stage homogeneous is 20Mpa. The homogeneous slurry is filled into cans while it is hot, and after degassing, it is 0.03g / kg almond Add nano-ZnO antibacterial agent, cover and seal, and then ...

Embodiment 3

[0043] Preparation of almond slurry: select sweet almonds and walnut kernels with good appearance, soak them in warm water at 42-48°C for 5-6 hours, peel them, and mix peeled almonds, walnut kernels with peanuts and corn according to the ratio of 6:1:2:1 After mixing and rinsing, add water to mix according to the weight-to-liquid ratio of 1:10, then put it in a refiner to grind for 10-15 minutes, and filter to get the filtrate;

[0044] Weigh 100 parts of prepared almond slurry, add 3 parts of sucrose, 1.7 parts of trehalose, 0.8 part of cyclodextrin, 0.3 part of salt and 0.3 part of stabilizer, stir and mix, boil the mixed slurry and cool down to 78 At ~82°C, carry out two-stage homogeneous reflux three times, of which the pressure of the first-stage homogeneous is 43-48Mpa, and the pressure of the second-stage homogeneous is 15-20Mpa. Add nano-ZnO bacteriostatic agent at 0.02~0.03g / kg almond dew, cover and seal, then sterilize in an autoclave. 37°C is enough.

[0045] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com