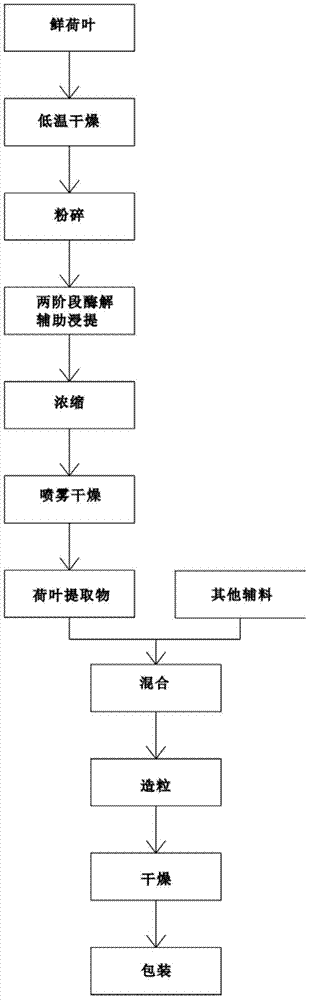

Instant solid lotus leaf beverage as well as processing method thereof

A technology for solid beverages and processing methods, applied in multi-step food processing, functions of food ingredients, food preparation, etc., can solve the problems of low extraction effect, bitter flavor, etc., achieve low cost, overcome bitter taste, and equipment requirements simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Wash the fresh lotus leaves and dry them with mechanical hot air at a temperature of 50°C until the water content is lower than 5%, then crush them with a low-temperature ultrafine pulverizer, pass through an 80-mesh sieve after crushing, and obtain lotus leaf powder. The ratio of lotus leaf powder and water is 1:30, and the mixed enzyme of pectinase and cellulase (1:1, enzyme activity 10000U / g) is added to the raw material according to 2.0g / kg, and the enzyme is hydrolyzed at 55°C The time is 2.0h, then the temperature is lowered and maintained at 33°C, and 1.0g / kg of tannase (enzyme activity 150U / g) is added according to the mass of raw materials for 1.5h. The lotus leaf extract after enzymolysis was vacuum-concentrated to 5Brix by vacuum concentration equipment, and then spray-dried at an inlet temperature of 175° C. and an outlet temperature of 75° C. to prepare lotus leaf extract. After mixing 10 parts of lotus leaf extract, 5 parts of longan powder, 80 parts of su...

Embodiment 2

[0032] The fresh lotus leaves are dried with hot air at 45°C until the water content is less than 5%, crushed and passed through a 100-mesh sieve to obtain lotus leaf powder. The ratio of lotus leaf powder and water is 1:40, and the mixed enzyme of pectinase and cellulase (1:1, enzyme activity 10000U / g) is added to the raw material according to 2.5g / kg. At 50°C, the enzymatic hydrolysis time 2.0h, then lower the temperature and maintain it at 35°C, add 1.5g / kg tannase (enzyme activity 150U / g) according to the raw material quality, and act for 1.0h. The lotus leaf extract after enzymolysis was vacuum-concentrated to 8Brix, and then spray-dried at an inlet temperature of 185°C and an outlet temperature of 85°C to prepare lotus leaf extract. After mixing 15 parts of lotus leaf extract, 6 parts of sweet orange powder, 75 parts of sucrose powder and 4 parts of maltodextrin according to the quality, add a small amount of water and mix well, and use a swing granulator to granulate th...

Embodiment 3

[0034] Dry the fresh lotus leaves with hot air at 46°C until the water content is less than 5%, crush them and pass them through a 100-mesh sieve to obtain lotus leaf powder. The ratio of lotus leaf powder and water is 1:35, and the mixed enzyme of pectinase and cellulase (1:1, enzyme activity 10000U / g) is added to the raw material according to 3.0g / kg. At 52°C, the enzymatic hydrolysis time 1.5h, then lower the temperature and maintain it at 35°C, add 1.5g / kg tannase (enzyme activity 150U / g) according to the raw material quality, and act for 1.5h. The lotus leaf extract after enzymolysis was vacuum-concentrated to 8Brix, and then spray-dried at an inlet temperature of 180°C and an outlet temperature of 80°C to prepare lotus leaf extract. After mixing 10 parts of lotus leaf extract, 5 parts of peppermint extract, 80 parts of sucrose powder and 5 parts of maltodextrin according to the quality, add a small amount of water and mix well, and use a swing granulator to pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com