Method for reducing smoke CO (carbon oxide) release amount of paper-making reconstituted tobaccos

A technology of reconstituted tobacco leaves and papermaking method, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of reducing CO emission, changing the air permeability of paper, and affecting product quality. It achieves simple adding methods, low adding costs, and high application convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

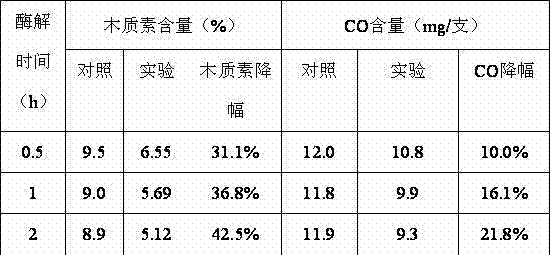

Embodiment 1

[0016] The lignin compound enzyme is prepared, and its component and mass ratio is lignin peroxidase (Lip): manganese peroxidase (Mnp): laccase (Lac)=1:1:2. Add lignin compound enzyme to the pulping section of tobacco pulp produced by papermaking method to reconstitute tobacco leaves to enzymatically hydrolyze the pulp. The enzymatic hydrolysis conditions are: the concentration of tobacco pulp is 3% (100kg dry weight), and the degree of beating is 25. ° SR, the amount of enzyme added is 300u / g, the enzymolysis temperature is 35°C, and the reaction is carried out under stirring for 0.5 hours, 1 hour, and 2 hours (i.e. the enzymolysis time). The lignin compound enzyme slurry was used as a parallel control sample. The slurry with low lignin content obtained after enzymatic hydrolysis is copied into a substrate according to the prior art method, and then coated and dried to obtain a low-CO reconstituted tobacco product, which is cut into shreds and rolled into reconstituted tobacc...

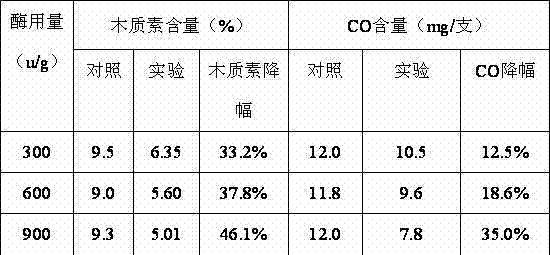

Embodiment 2

[0020] The lignin compound enzyme is prepared, and its component and mass ratio is lignin peroxidase: manganese peroxidase: laccase=1:3:0.5. Add lignin compound enzyme to the pulping section of tobacco pulp produced by papermaking method to reconstitute tobacco leaves to enzymatically hydrolyze the pulp. The enzymatic hydrolysis conditions are: the concentration of tobacco pulp is 1% (absolute dry weight 100kg), and the degree of beating is 32. ° SR, the amount of enzyme added is 300u / g, 600u / g, 900u / g respectively, the enzymolysis temperature is 25°C, and the reaction is stirred for 2 hours. After the reaction, the slurry is dried to measure the lignin content. The material is a parallel control sample. The slurry with low lignin content obtained after enzymatic hydrolysis is made into a substrate, coated and dried to obtain a low-CO reconstituted tobacco leaf product. Shred the reconstituted tobacco leaf products, roll them into reconstituted tobacco leaf cigarettes (the we...

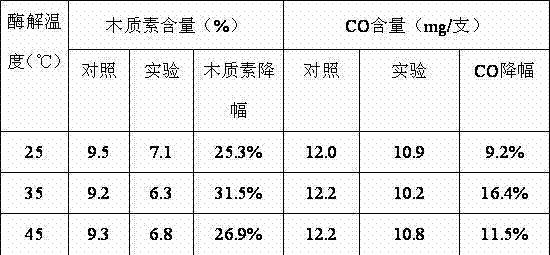

Embodiment 3

[0024] The lignin complex enzyme is prepared, and its component and mass ratio is Lip:Mnp:Lac=1:5:4. Add lignin compound enzyme to enzymatically hydrolyze the pulp of tobacco pulp produced by papermaking reconstituted tobacco leaves. The enzymatic hydrolysis conditions are: the concentration of tobacco pulp is 5% (100kg dry weight), and the degree of beating is 18. ° SR, the amount of enzyme added is 600u / g, and the reaction is stirred at 25°C, 35°C, and 45°C respectively. The reaction time is the enzymolysis time of 2 hours. The compound enzyme slurry was used as a parallel control sample. The slurry with low lignin content obtained after enzymatic hydrolysis is made into a substrate, coated and dried to obtain a low-CO reconstituted tobacco leaf product. Shred the reconstituted tobacco leaf products, roll them into reconstituted tobacco leaf cigarettes (the weight of a single cigarette sample is 0.8±0.03), equilibrate overnight at a constant temperature of 23±1°C and a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com