Cellulose-chitosan compound and preparation method thereof

A technology of chitosan and cellulose, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. The problem of high price of ionic liquid, to achieve the effect of low cost, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

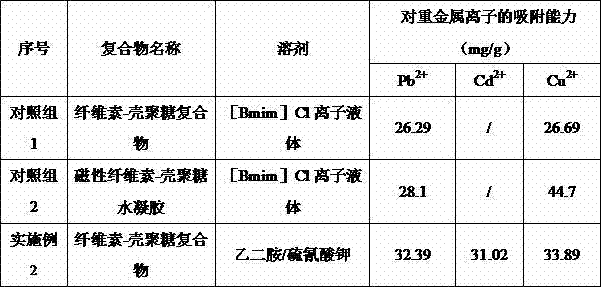

Image

Examples

preparation example Construction

[0018] A kind of cellulose-chitosan compound, its preparation method comprises the following steps:

[0019] 1) Dissolve potassium thiocyanate in ethylenediamine, wherein the weight ratio of potassium thiocyanate to ethylenediamine is (1:4)~(3:7). diamine solution;

[0020] 2) Divide the ethylenediamine solution of potassium thiocyanate into two parts, add cellulose powder and chitosan powder respectively, and prepare the cellulose solution and the dispersion system containing chitosan respectively, wherein the cellulose and chitosan The mass concentration is independently 1-5%;

[0021] 3) Mix the cellulose solution and the chitosan-containing dispersion system according to the mass ratio (1-4): 1, and use the dry spray wet spinning process to prepare the cellulose-chitosan composite, and then dry , you can.

[0022] In step 2), before adding cellulose powder and chitosan powder, the ethylenediamine solution of potassium thiocyanate is cooled to -10°C ~ -20°C to improve th...

Embodiment 1

[0027] 1) Dissolve potassium thiocyanate in ethylenediamine, wherein the weight ratio of potassium thiocyanate to ethylenediamine is 1:4, and dissolve completely;

[0028] 2) Divide the ethylenediamine solution of potassium thiocyanate into two parts, and freeze to -10°C, then add cellulose powder and chitosan powder respectively to prepare the cellulose solution and the dispersion system containing chitosan, respectively, The mass concentrations of cellulose and chitosan are both 1%.

[0029] 3) The cellulose solution and the dispersion system containing chitosan were mixed evenly according to the mass ratio of 2:1, and the cellulose-chitosan composite was prepared by using the dry spray wet spinning process and using water as the coagulation bath. Then dry it at 50°C.

Embodiment 2

[0031] 1) Dissolve potassium thiocyanate in ethylenediamine, wherein the weight ratio of potassium thiocyanate to ethylenediamine is 3:7, and dissolve completely;

[0032] 2) Divide the ethylenediamine solution of potassium thiocyanate into two parts, and freeze to -19°C, then add cellulose powder and chitosan powder respectively to prepare the cellulose solution and the dispersion system containing chitosan, respectively, The mass concentrations of cellulose and chitosan are both 4.8%.

[0033] 3) The cellulose solution and the dispersion system containing chitosan were mixed evenly according to the mass ratio of 1:1, and the cellulose-chitosan composite was prepared by using the dry spray wet spinning process and using methanol as the coagulation bath. Then freeze and dry in vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com