Method for preparing potassium manganate

A technology of potassium manganate and potassium hydroxide, applied in the directions of manganate/permanganate and the like, can solve the problems of the preparation method of potassium manganate needing to be improved, the conversion rate of manganese dioxide is low, the recovery rate of KOH is low, and the like. Significant energy saving and environmental protection, high recovery rate, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

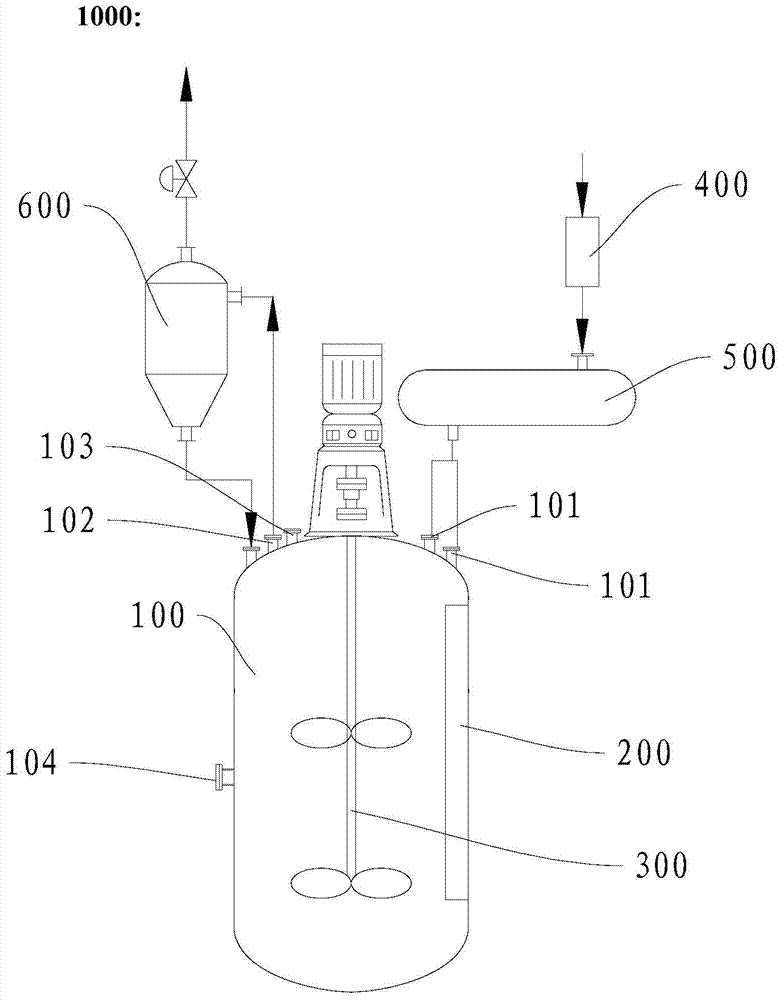

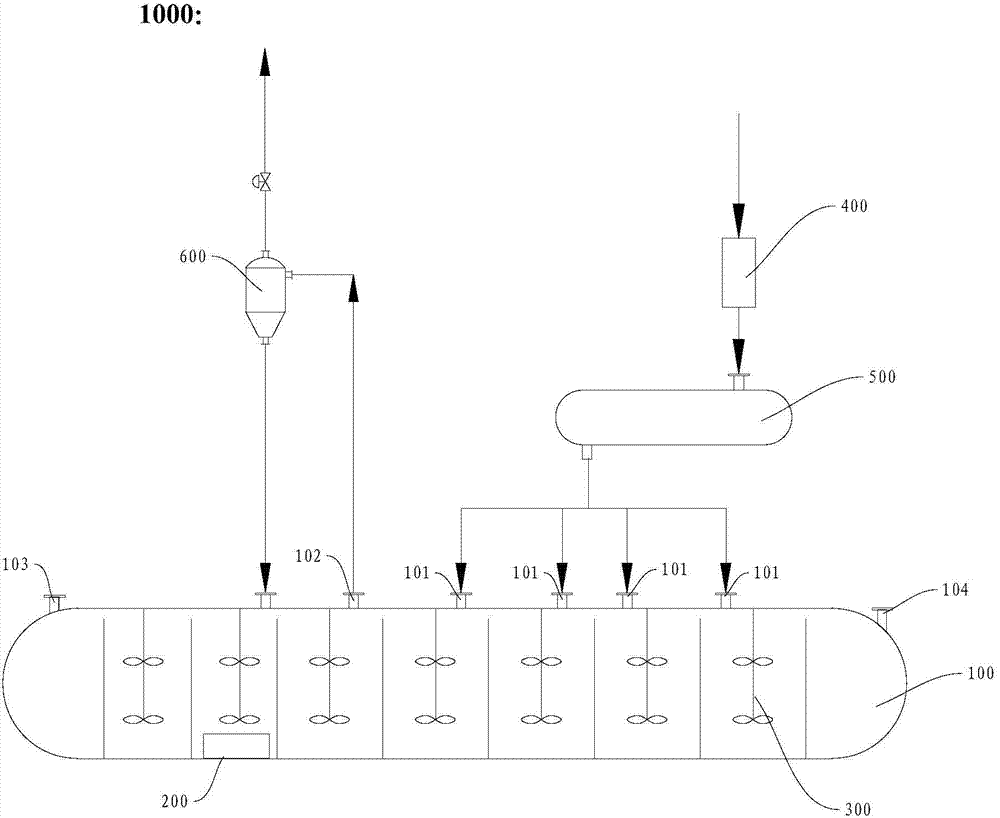

[0052] The above part has described in detail the method for preparing potassium manganate of the present invention. In order to better understand the method, the equipment capable of implementing the method will be described in detail below.

[0053] According to another aspect of the present invention, the present invention also provides a reactor 1000 . According to an embodiment of the present invention, refer to figure 2 and image 3 , the reactor 1000 includes: a body 100 , a slurry heating device 200 and a stirring device 300 . The inventors surprisingly found that the reactor 1000 of the present invention can efficiently prepare potassium manganate, and the reactor is simple in structure, easy to operate, uses clean energy, has high heat utilization rate, and is easy to realize large-scale industrial production.

[0054] According to an embodiment of the present invention, a reaction space is defined in the body 100, an oxygen inlet 101, a waste oxygen outlet 102, a...

Embodiment 1

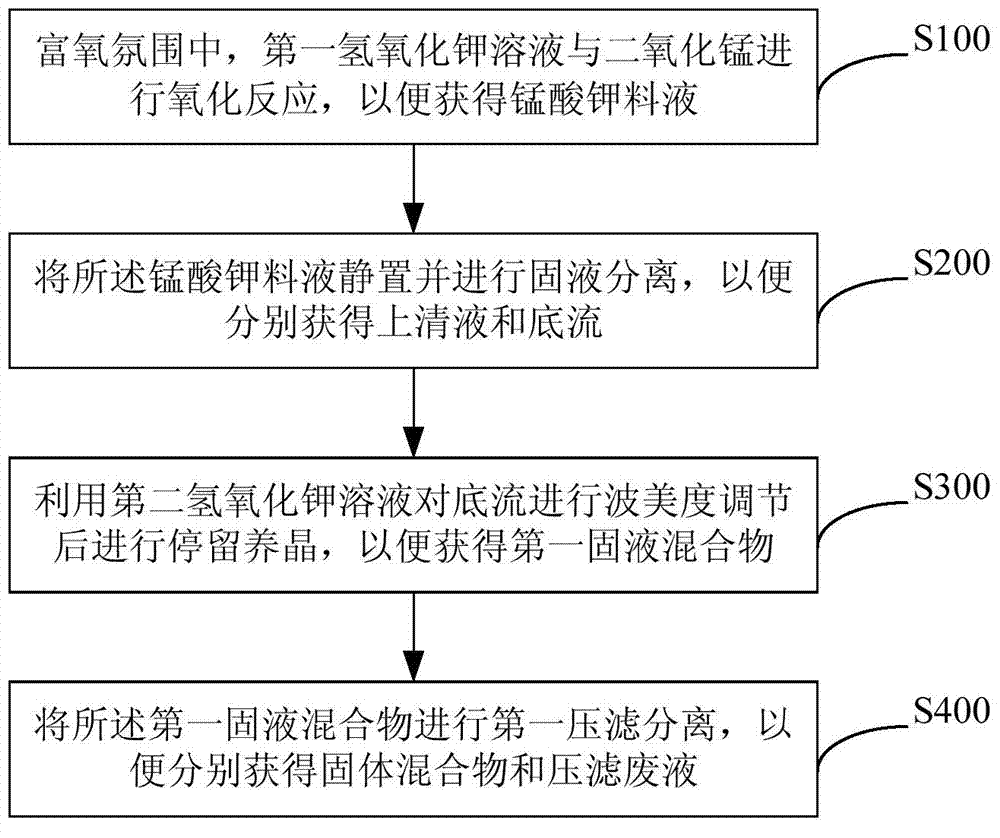

[0077] use figure 2 or image 3 The reactor shown, and Figure 4 Shown system, according to the method for preparing potassium manganate described above, prepare potassium manganate according to the following steps:

[0078] a. Oxidation reaction: the first potassium hydroxide solution with a concentration of 45-70% by weight is mixed with pyrolusite in a ratio of 1:5-15 according to the mass ratio of manganese dioxide and potassium hydroxide in the first potassium hydroxide solution Ore slurry is formed, and oxidation reaction is carried out in an oxygen-enriched atmosphere at 250-260 degrees Celsius and 0.2-1.2Mpa to obtain potassium manganate feed liquid;

[0079] b. Solid-night separation: After the potassium manganate feed liquid is allowed to stand for an appropriate time, solid-liquid separation is carried out so as to obtain supernatant and underflow respectively;

[0080] c. Stay crystal growth: use the second potassium hydroxide solution to adjust the Baume degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com