Preparation method of high-solid-content hydroxyl waterborne polyurethane resin

A water-based polyurethane and hydroxyl-type technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor elasticity of water-based polyurethane coatings, increase the drying time of coating films, and weak dispersion of curing agents, etc., to increase flexibility Excellent properties, improved crosslink density, and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of high solid hydroxyl type waterborne polyurethane resin, according to the following steps:

[0028] 1) Add polyester diol, hydroxyl-terminated sulfonate polyester diol, small molecule diol, polyol, and hydrophilic monomer into the reaction vessel for mixing and dehydration;

[0029] 2) Slowly add diisocyanate at 60-65°C for 1 hour and keep warm for 1 hour;

[0030] 3) Add a catalyst, raise the temperature to 65-70°C and keep it warm for reaction, and stop heating when the isocyanate content is detected to be less than or equal to 0.1wt%;

[0031] 4) Cool down to 40-50°C, adjust viscosity with acetone, and neutralize to 7-8 with organic amine;

[0032] 5) Add deionized water to disperse for 30 minutes under high-speed stirring at 35-40°C, and remove acetone under reduced pressure to obtain milky white and bluish hydroxyl-type water-based polyurethane resin;

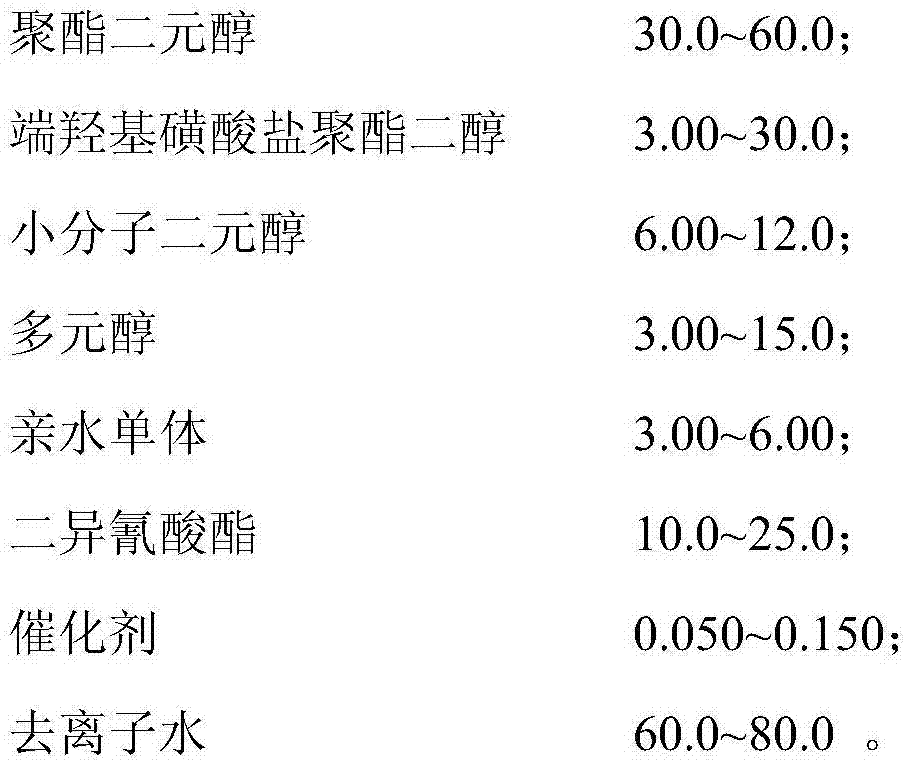

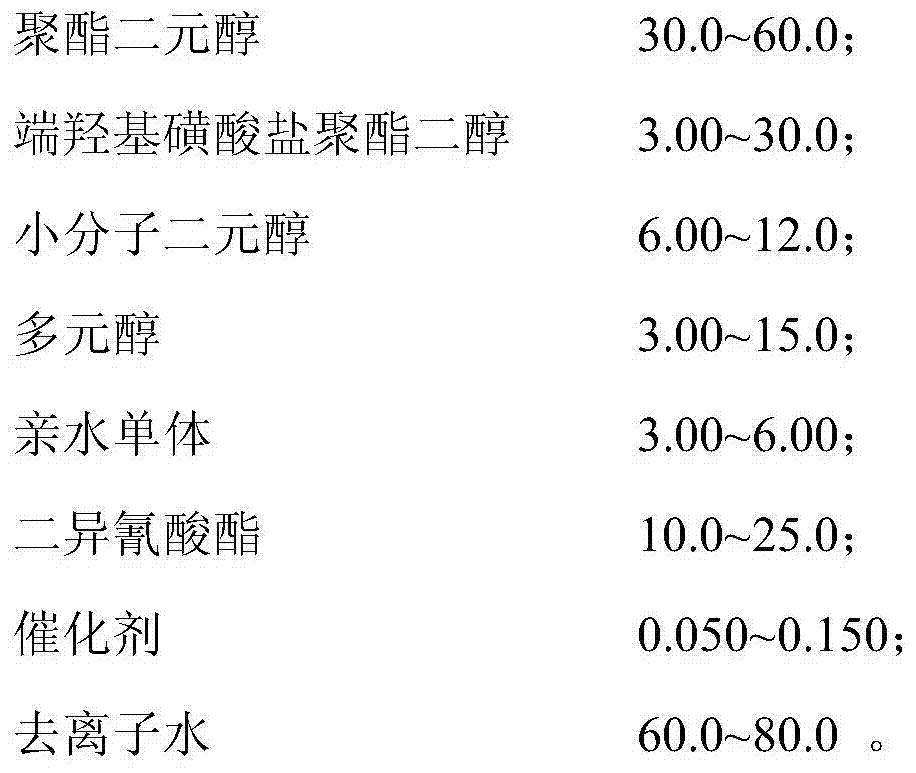

[0033] Wherein, the above-mentioned raw materials are calculated in parts by weight as...

Embodiment 1

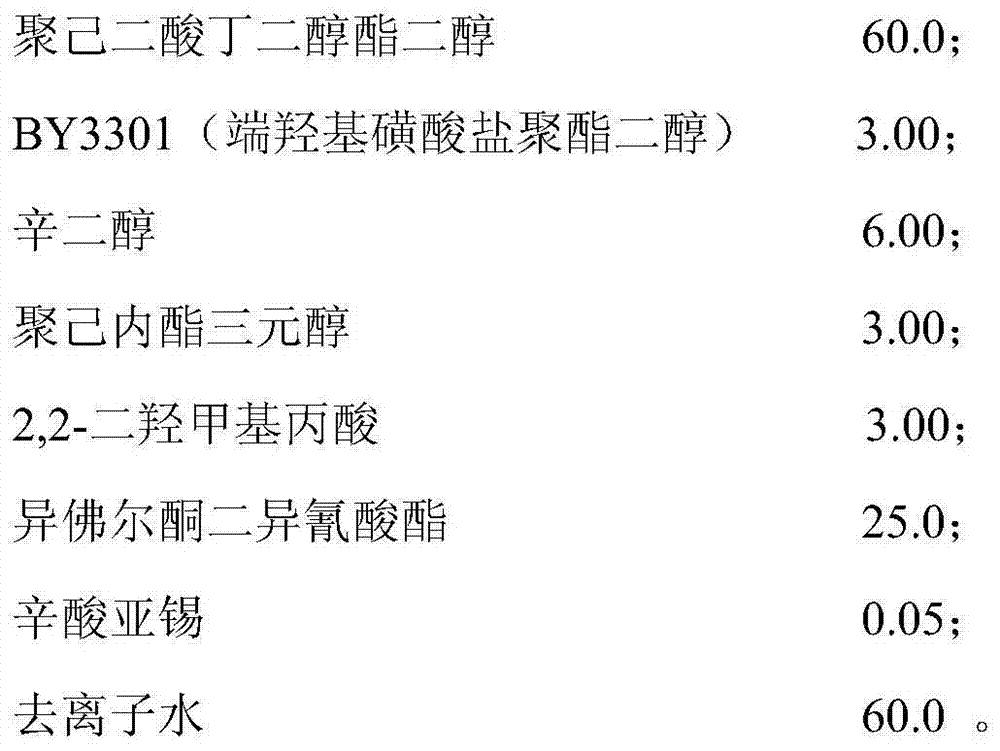

[0036] 1) Polybutylene adipate diol (molecular weight 1000), hydroxyl-terminated sulfonate polyester (BY3301 produced by Beijing Baiyuan Chemical Co., Ltd.), octane glycol, polycaprolactone triol (molecular weight 500), 2,2-dimethylolpropionic acid was added to the reaction vessel and mixed, and vacuumed at 0.05MPa, 107°C for 1h to remove moisture;

[0037] 2) Remove the vacuum, pass in nitrogen protection, slowly add isophorone diisocyanate dropwise at 65°C, finish adding dropwise for 1 hour and keep warm for another hour;

[0038] 3) Add stannous octoate, raise the temperature to 70°C and keep it warm for reaction, and stop heating when the isocyanate content is detected to be less than or equal to 0.1wt%;

[0039] 4) Cool down to 50°C, adjust the viscosity with acetone, and neutralize it to 7-8 with dimethylethanolamine;

[0040] 5) Add deionized water to disperse for 30 minutes under high-speed stirring at 45°C, and remove acetone under reduced pressure to obtain milky wh...

Embodiment 2

[0048] 1) Polyneopentyl adipate diol (molecular weight 1000), sulfonate polyester with terminal hydroxyl group (BY3305 produced by Beijing Baiyuan Chemical Co., Ltd.), hexanediol, castor oil, 2,2-diol Methylolpropionic acid was added to the reaction vessel for mixing, and vacuumed at 0.05MPa, 107°C for 1 hour to remove moisture;

[0049] 2) Remove the vacuum, pass in nitrogen protection, slowly add toluene diisocyanate dropwise at 60°C, finish adding dropwise for 1 hour and keep warm for 1 hour;

[0050] 3) Add dibutyltin dilaurate, raise the temperature to 65°C and keep it warm for reaction, and stop heating when the isocyanate content is detected to be less than or equal to 0.1wt%;

[0051] 4) Cool down to 40°C, adjust the viscosity with acetone, and neutralize it to 7-8 with triethylamine;

[0052] 5) Add deionized water to disperse for 30 minutes under high-speed stirring at 35°C, and remove acetone under reduced pressure to obtain milky white and bluish hydroxyl-based po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com