Combustion heat supply system taking biomass as fuel

A technology of burning heating and biomass, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of close distance from the city, high pollutant emission concentration, environmental pollution, etc., to achieve the effect of improving thermal efficiency and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

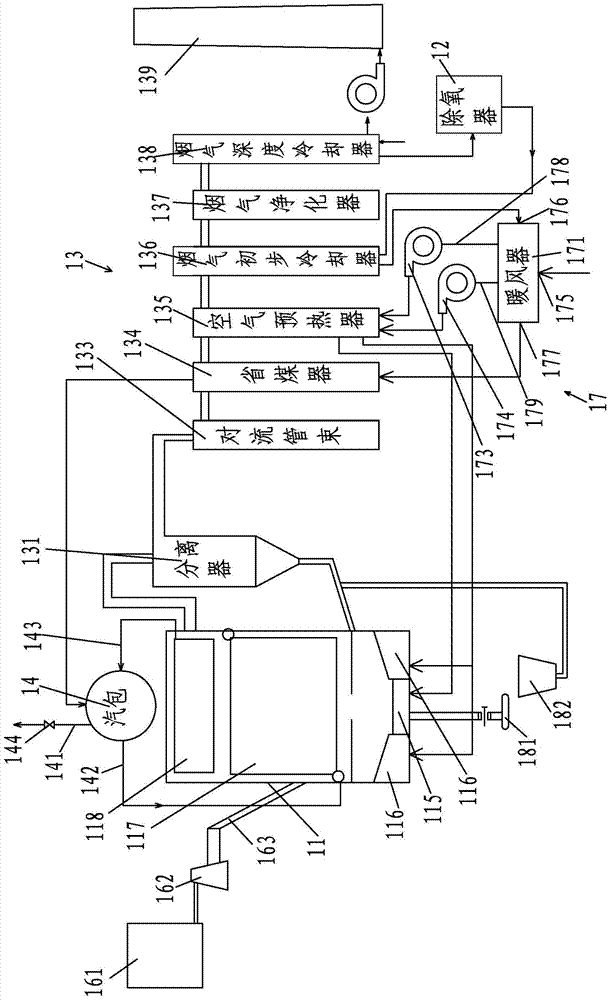

[0013] Such as figure 1 As shown, the combustion heating system using biomass as fuel in the present invention includes a combustion boiler 11, a flue gas discharge device 13, and an air supply device 17. The flue gas discharge device includes a cyclone separator 131, and the inlet of the cyclone separator 131 is connected to the combustion boiler 11, the flue gas outlet of the cyclone separator 131 is connected to the inlet of the convection tube bundle 133, and the solid matter outlet of the cyclone separator 131 communicates with the combustion zone of the combustion boiler 11 through its lower return pipe, and the combustion of the combustion boiler There are main and auxiliary combustion beds 115 and 116 in the area, and an economizer 134, a flue gas preliminary cooler 136, a flue gas purifier 137, and a flue gas deep cooler are arranged in sequence along the flue gas flow direction downstream of the convection tube bundle 133. 138 and anti-corrosion chimney 139, the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com