An air-conditioning heat pump unit with an antifreeze solution regeneration device

A technology of antifreeze solution and heat pump unit, which is applied in the direction of air conditioning system, heating and cooling combination, space heating and ventilation, etc. It can solve the problems of increasing the operating cost of antifreeze, expansion and cracking of evaporative condenser components, and restricting the applicable area. , to achieve the effect of recycling water resources, improving energy utilization, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

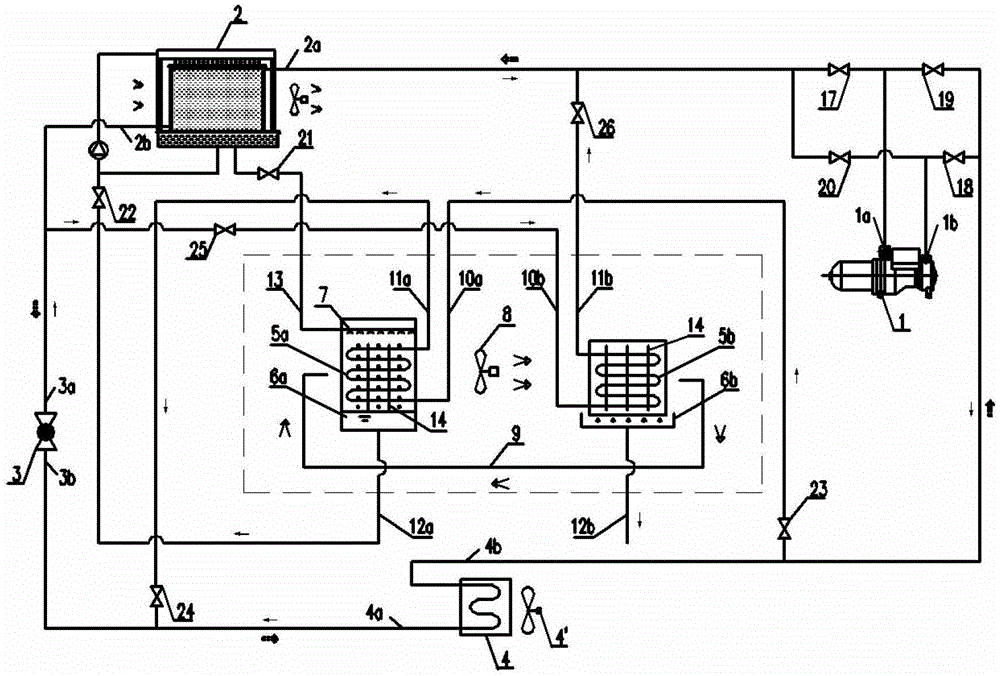

[0037] This embodiment is an air conditioner heat pump unit with an antifreeze solution regeneration device, which has a refrigeration cycle mode and a heat pump cycle mode. Such as figure 1 As shown, it includes a compressor 1, an evaporative condenser 2, a throttling device 3, an evaporator 4 and a blower 4'; this unit also includes an antifreeze solution regeneration device, and the antifreeze solution regeneration device is arranged on the cooling side of the evaporative condenser in the water system.

[0038]The unit is provided with a first refrigeration valve 17, a second refrigeration valve 18, a first heat pump valve 19 and a second heat pump valve 20; On the connecting pipeline of the pipe 2a, the second refrigeration valve is set on the connecting pipeline between the suction port 1b of the compressor and the gas pipe 4b of the evaporator, and the first heat pump valve is set on the exhaust port of the compressor and the gas pipe of the evaporator. On the connecti...

Embodiment 2

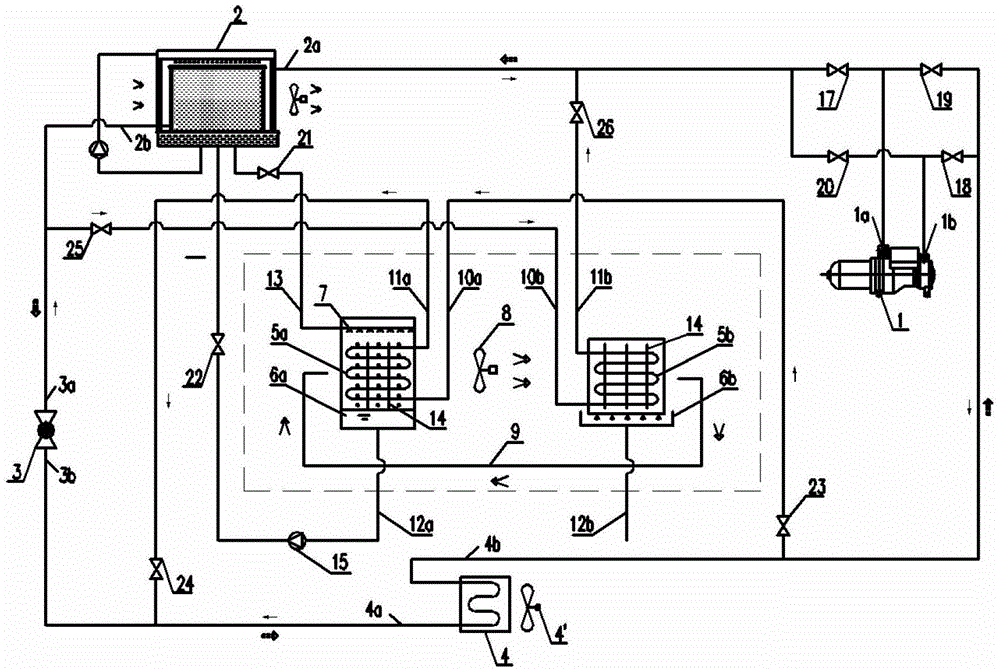

[0045] This embodiment provides another air-conditioning heat pump unit with an antifreeze solution regeneration device, such as figure 2 As shown, compared with Example 1, the difference is that, in order to make the high-concentration solution return to the evaporative condenser 2 more smoothly, a solution pump 15 is added to the concentrated solution outlet 12a in the solution collecting pan 6a, so that the high-concentration solution The concentrated solution returns to the evaporative condenser 2 after being pressurized by the solution pump 15 .

Embodiment 3

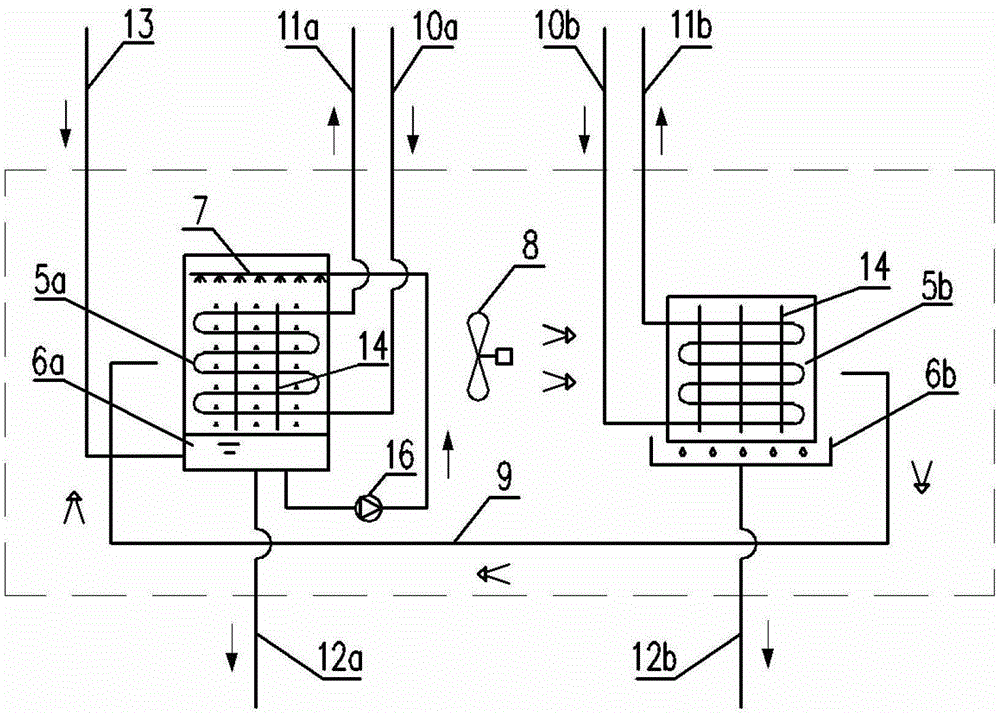

[0047] This embodiment is as a kind of improvement of embodiment 1, as image 3 As shown, compared with Example 1, in order to facilitate the evaporation of water content of the low-concentration antifreeze solution and form a concentrated solution, the difference is that a spray circulation pump 16 is added, and the inlet of the spray circulation pump 16 is connected to the solution The liquid collecting tray 6a, the outlet of the spray circulation pump 16 is connected to the sprayer 7, and the low-concentration solution channel 13 is connected to the solution collecting tray 6a, so that the spray solution can be circulated through the high-temperature heat source 5a for many times, thereby achieving moisture content. The requirement for a higher concentration of the solution after more evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com