Magnetic porous cobalt hollow ball electromagnetic wave absorption material, preparation method and application thereof

A technology of absorbing materials and hollow spheres, which is applied in the fields of inorganic material magnetism, instruments, shielding, etc., can solve the problems of large eddy current loss, low material dispersion, weak absorption intensity, etc., and achieves wide absorption coverage frequency range, simple preparation process, The effect of high saturation susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Technical scheme of the present invention is as follows:

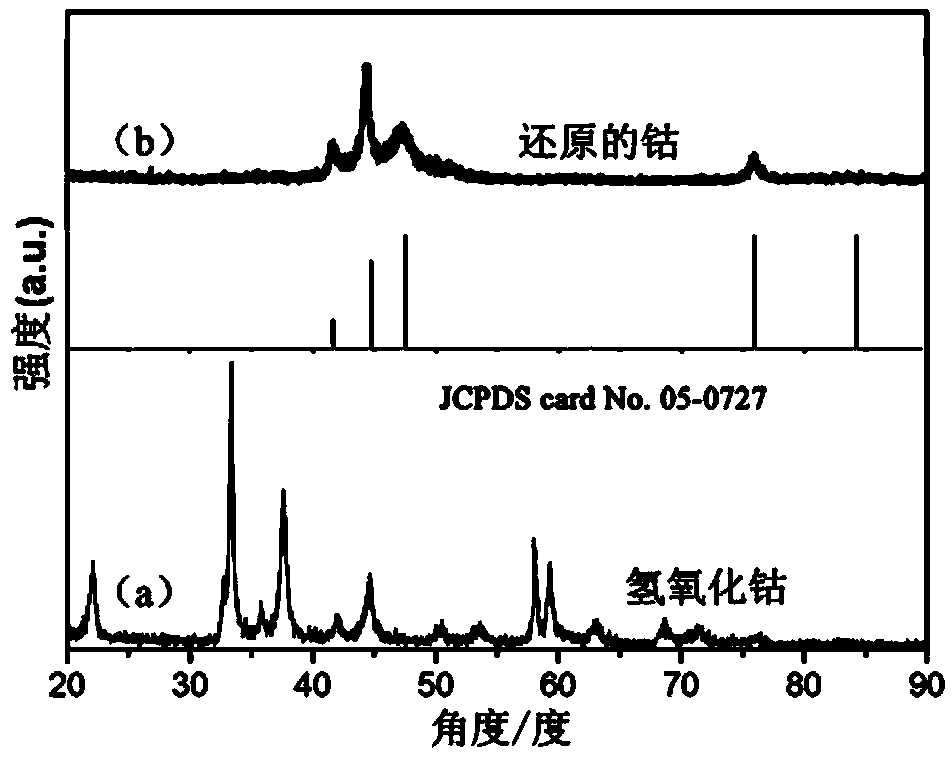

[0008] A magnetic porous cobalt hollow sphere electromagnetic wave absorbing material, which is prepared by chemical reduction by a template-free synthesis method; the outer diameter of the porous cobalt hollow sphere is 2-6 microns, and the thickness of the spherical shell is 100-200nm; the porous cobalt hollow sphere The spheres are composed of particles with a diameter of 60-200nm, and pores with a size of 10-100nm exist between the particles. The magnetic porous cobalt hollow sphere has the characteristics of monodispersion.

[0009] According to the present invention, preferably, the outer diameter of the porous cobalt hollow sphere is 2-3 microns, and the thickness of the spherical shell is 100-150 nm.

[0010] According to the present invention, preferably, the porous cobalt hollow spheres are composed of particles with a diameter of 60-150 nm, and there are pores with a size of 10-50 nm between the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com