Method for repairing cracks in installing support of combustion box

A technology for mounting brackets and combustion chambers, applied in the field of repairs, can solve the problems of large welding deformation, complex design and manufacture of tooling, and low production efficiency, and achieve the effects of preventing oxidation, discoloration or burning, improving production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

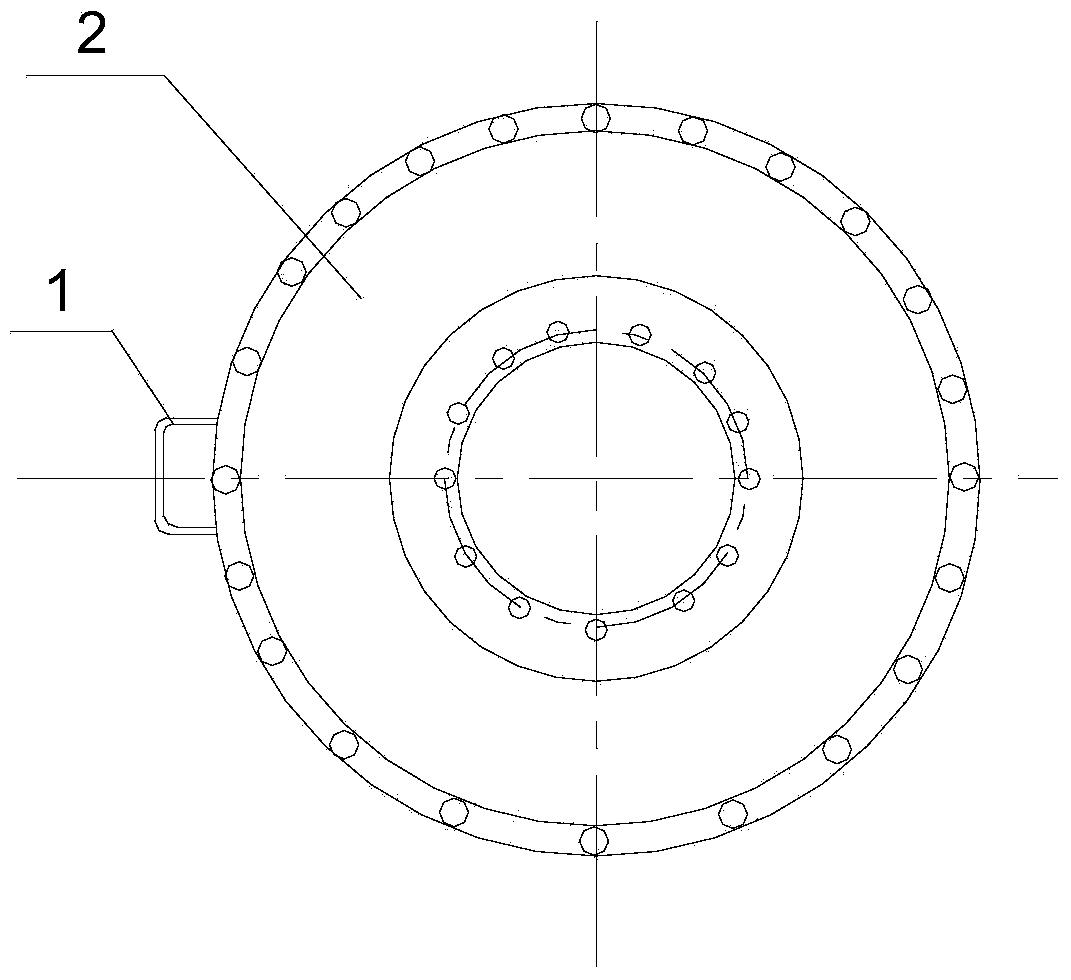

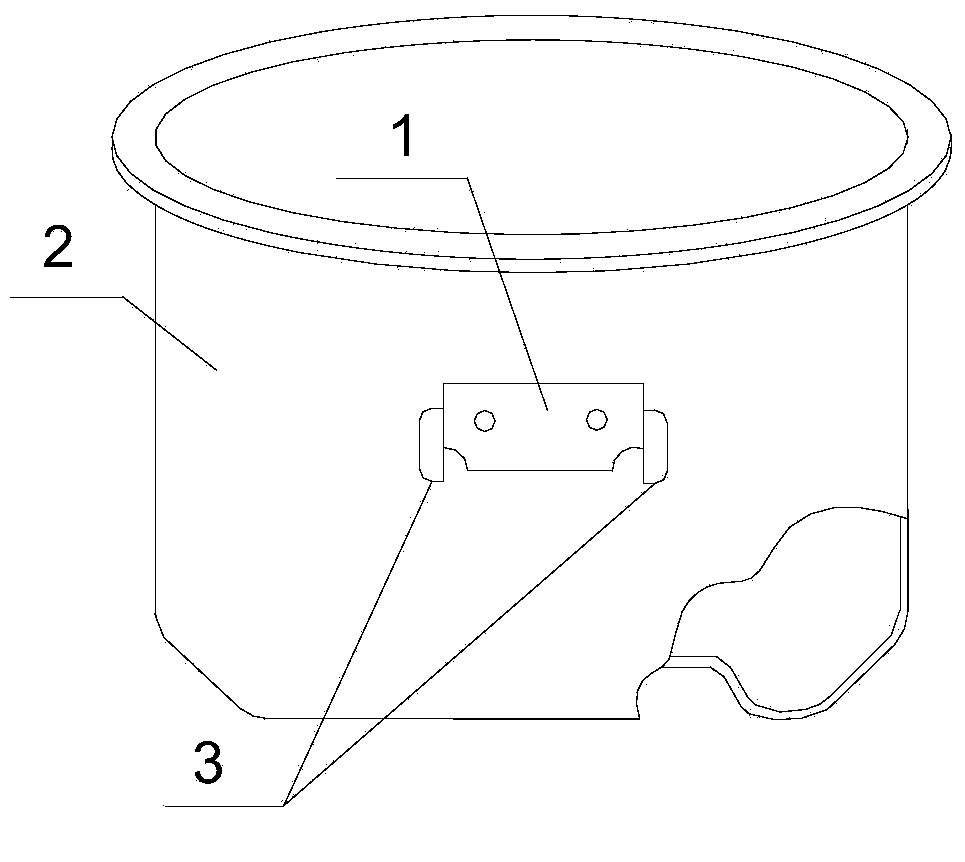

[0022] The casing of an aero-engine combustor, after being used for a period of time, has cracks in the mounting bracket, which needs to be repaired, and it is required that there are no cracks and linear defects after the repair. The specific implementation steps are as follows:

[0023] 1) Pre-weld inspection: Fluorescence inspection is carried out on the casing to be repaired to determine the specific location of the crack defect at the bracket; the crack is located at the vacuum brazing seam connection between the mounting bracket and the casing main body. ;

[0024] 2) Mechanical cleaning: Use a wind grinding wheel to polish the cracks on the brazed welds at the mounting bracket, and wipe the polished area with a white Dacron cloth dipped in alcohol or acetone until the white cloth does not turn black;

[0025] 3) Ultrasonic cleaning: Ultrasonic cleaning is performed on the combustion chamber casing and brazing wire to be repaired until the dirt on the entire part and the...

Embodiment 2

[0030] Another kind of aero-engine combustor casing, after a period of use, the mounting bracket has cracks, and it is repaired, and it is required that there are no cracks and linear defects after the repair. The specific implementation steps are:

[0031] 1) Pre-weld inspection: Fluorescence inspection is carried out on the casing to be repaired to determine the specific location of the crack defect at the bracket; the crack is located at the vacuum brazing seam connection between the mounting bracket and the casing main body. ;

[0032] 2) Mechanical cleaning: Use a wind grinding wheel to polish the cracks on the brazed welds at the mounting bracket, and wipe the polished area with a white Dacron cloth dipped in alcohol or acetone until the white cloth does not turn black;

[0033] 3) Ultrasonic cleaning: Ultrasonic cleaning is performed on the combustion chamber casing and brazing wire to be repaired until the dirt on the entire part and the surface of the welding wire is ...

Embodiment 3

[0038] The third type is an aero-engine combustor casing. After a period of use, the mounting bracket produces cracks. Repair it, and require no cracks and linear defects after the repair. The specific implementation steps are:

[0039] 1) Pre-weld inspection: Fluorescence inspection is carried out on the casing to be repaired to determine the specific location of the crack defect at the bracket; the crack is located at the vacuum brazing seam connection between the mounting bracket and the casing main body. ;

[0040] 2) Mechanical cleaning: Use a wind grinding wheel to polish the cracks on the brazed welds at the mounting bracket, and wipe the polished area with a white Dacron cloth dipped in alcohol or acetone until the white cloth does not turn black;

[0041] 3) Ultrasonic cleaning: Ultrasonic cleaning is performed on the combustion chamber casing and brazing wire to be repaired until the dirt on the entire part and the surface of the welding wire is removed;

[0042] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com