Resource recycling method of waste polymeric microfiltration/ultrafiltration membrane

A polymer and ultrafiltration membrane technology, applied in recycling technology, plastic recycling, etc., can solve problems such as environmental pollution, and achieve the effects of simple process, mild reaction conditions and fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

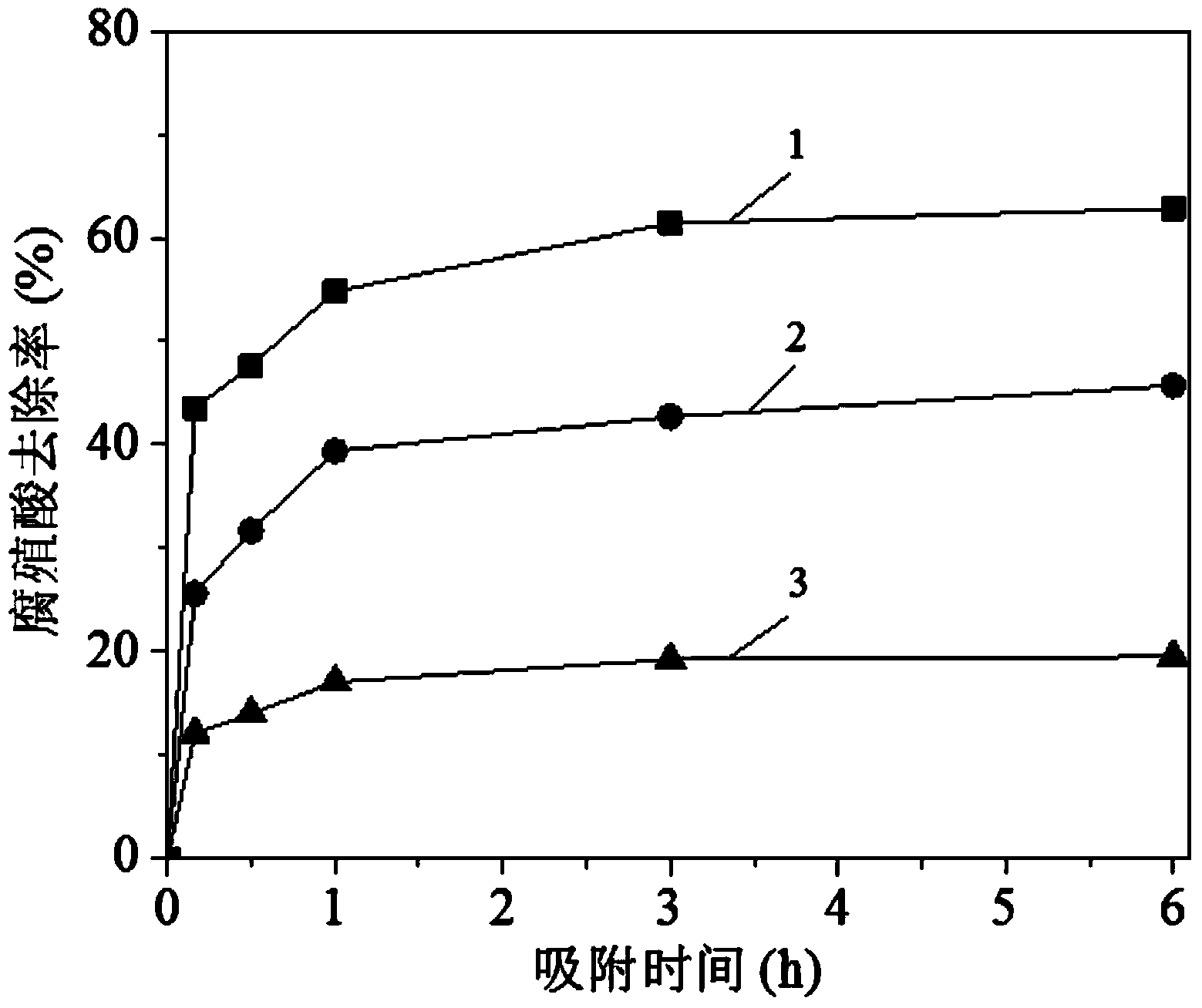

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode 1: In this implementation mode, a method for resource recovery and utilization of waste polymer microfiltration / ultrafiltration membrane is carried out according to the following steps:

[0022] 1. Cleaning and drying of waste filter membranes: Soak waste filter membranes in sodium hypochlorite solution with available chlorine content of 0.05% to 0.2%, alkali solution with pH=10 to 12 and acid solution with pH=2 to 3. The time is 1h to 5h, take it out, wash it with water for 1 to 2 times, take it out and dry it naturally to obtain a dry filter membrane;

[0023] Two, the preparation of macromolecule solution: the dry filter membrane that obtains in step 1 is joined in the organic solvent that is soluble in water, after stirring and dissolving, add additive again, obtain macromolecule solution after additive dissolves;

[0024] Wherein, the mass ratio of the dry filter membrane to the water-soluble organic solvent is 1g:(20~100)mL; the mass r...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the waste filter membrane described in step 1 is a polymer microfiltration membrane or a polymer ultrafiltration membrane. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the waste filter membrane described in step 1 is polyvinylidene fluoride microfiltration membrane, polyvinyl chloride ultrafiltration membrane, polysulfone ultrafiltration membrane membrane or polyethersulfone microfiltration membrane. Other parameters are the same as in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com