Equipment and method for forming optical fiber bundle

A molding equipment and molding method technology, applied in the direction of coating, etc., can solve the problems of excessive twisting of optical fibers, different helix radii, and differences in the length of optical fiber ribbons, etc., and achieve the effects of tight bundled optical fibers, increased optical fiber density, and small mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

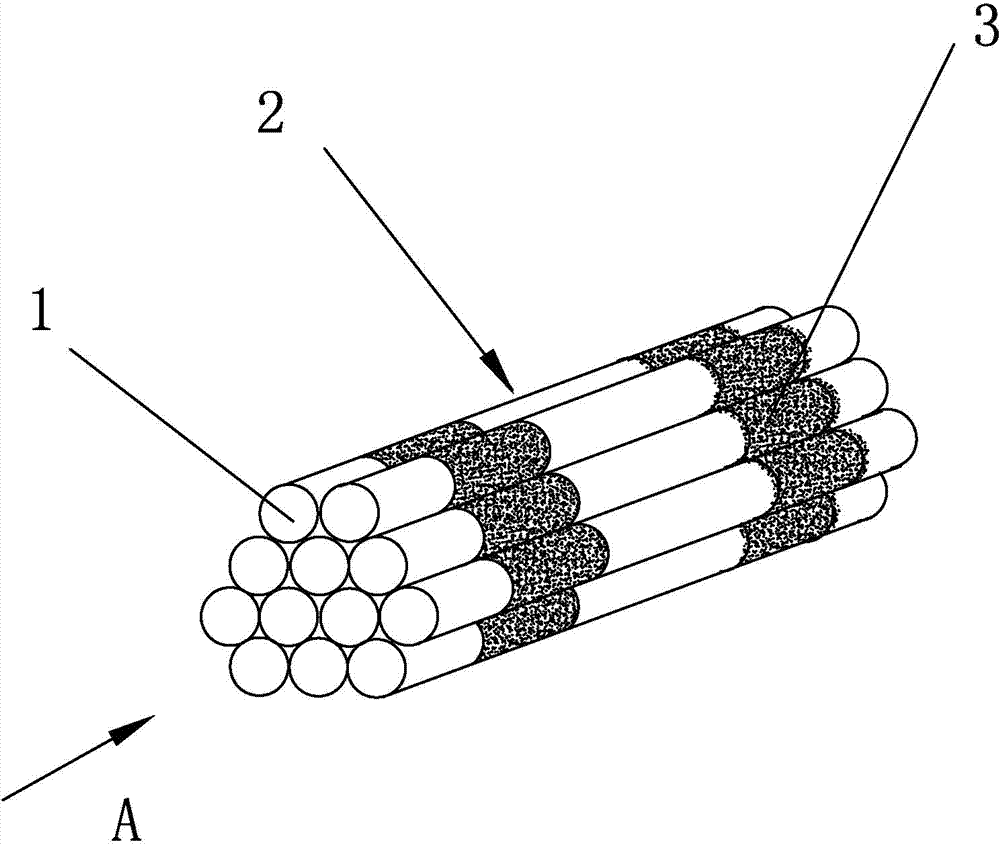

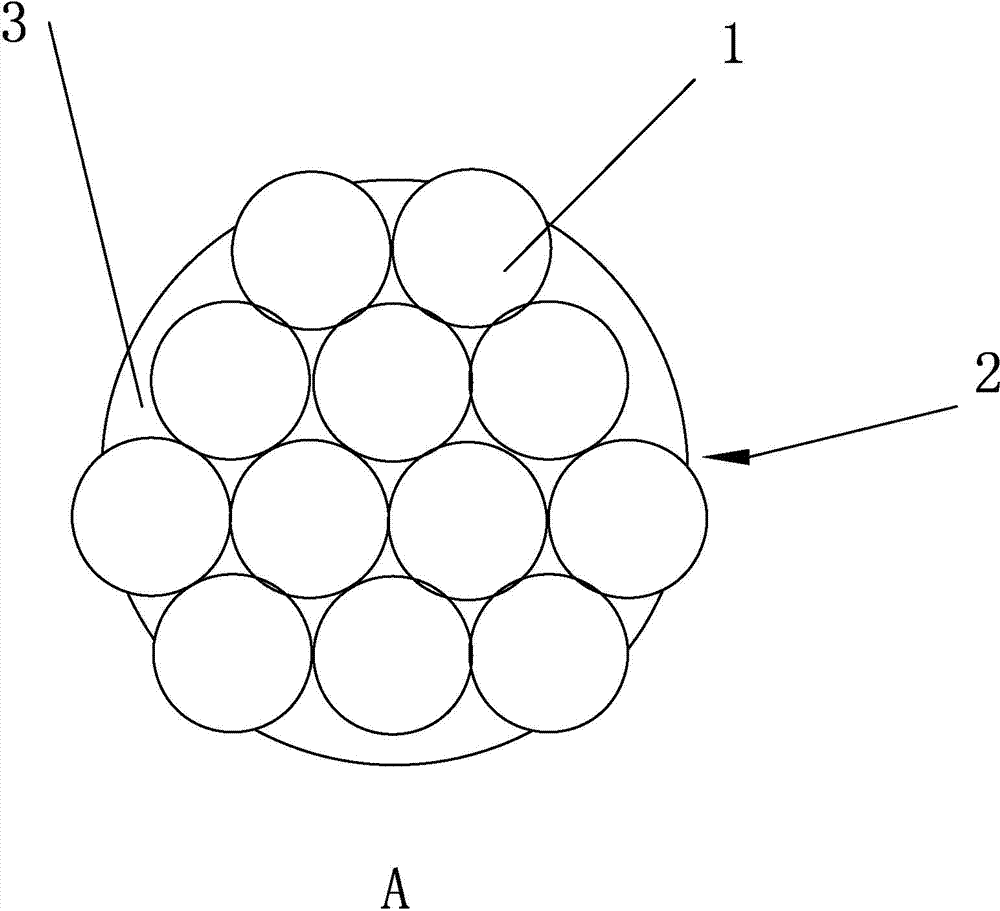

[0044] like Figure 3 to Figure 5 Shown, a kind of forming equipment of optical fiber bundle according to the present invention,

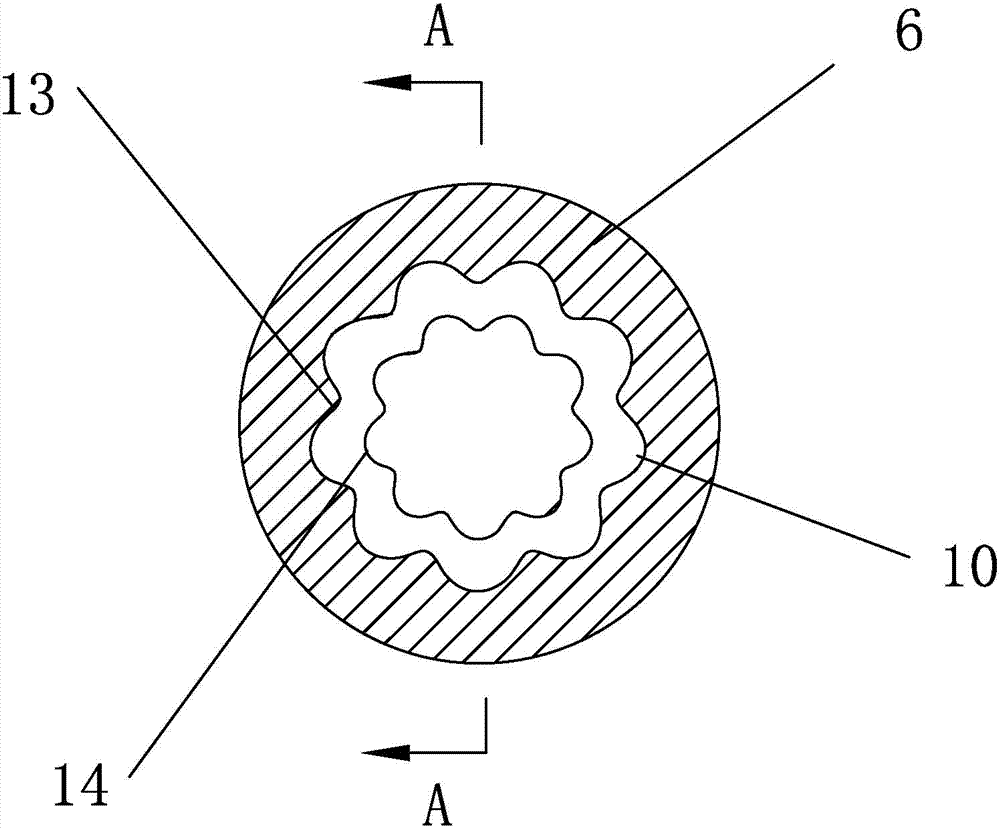

[0045]It sequentially includes a parallel tape pay-off machine 4 , a polymerization mold 5 , a preform mold 6 , an intermittent coating mold 7 , an ultraviolet light curing device 8 and a wire take-up device 9 . The preforming mold 6 has a forming cavity, the inner wall of the forming cavity is provided with a forming groove 10, the cross section of the forming cavity is formed by a plurality of arcs arranged in a circular array, one end of the forming cavity is set as the forming inlet 13, and the other end of the forming cavity is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com