Drought-resistant vegetation brick manufactured from sludge or biogas residue and manufacturing method thereof

A technology of biogas residue and sludge, applied in the application, fertilizer mixture, fertilization device, etc., can solve the problems of unreachable, no improvement of vegetation sand layer, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

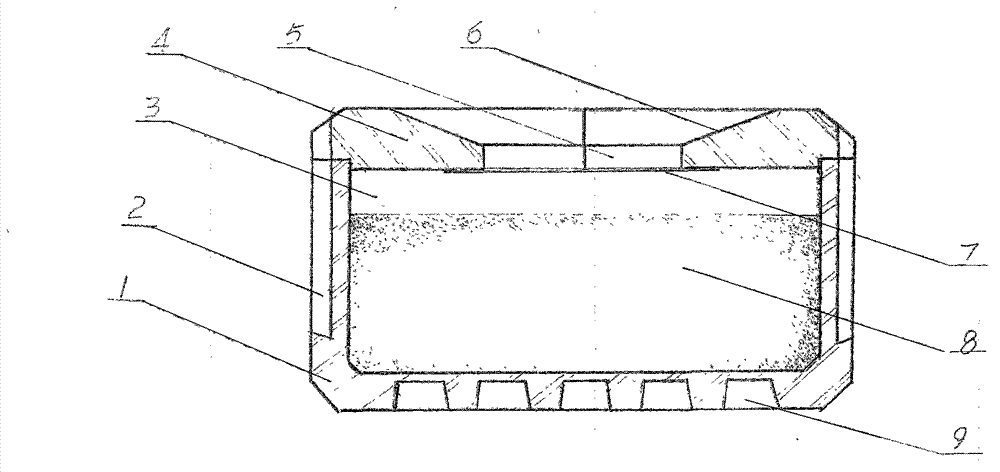

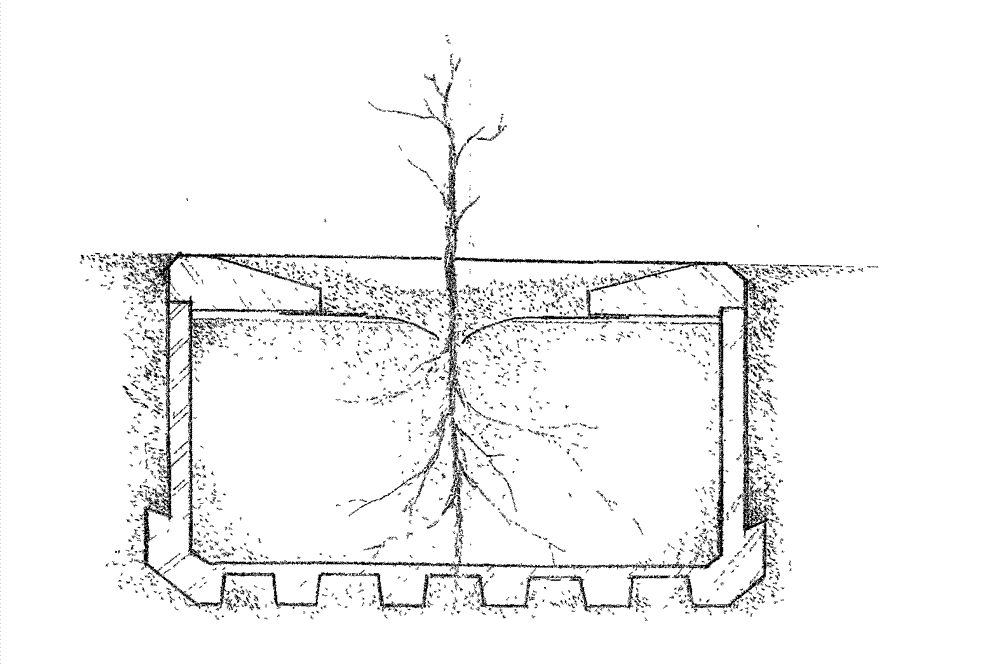

[0007] The present invention: the brick body 1 and the brick cover 4 are fresh sludge (moisture content 60%-65%, also called dry sludge, dry sludge or Fresh sludge, fresh biogas slag) and zeolite particles, humic acid, magnesium oxide are preferably mixed in a ratio of 5:3:1.3:0.7 in parts by weight 5:3:1.3:0.7 to prepare organic-inorganic composite bricks (containing water rate 30%-33%), and then made by molding and air-drying. The cavity 3 of the brick body is filled with decomposed organic fertilizer, vegetation ground sand, loam, and water-absorbing and water-retaining agent in a ratio of 2:6:1.9:0.1 in parts by weight and mixed uniformly to form a powder 8 . The bottom of the brick body 1 has a plurality of small blind holes 9 facing downwards, and the wall at the upper end of the blind holes is thinner and can gradually soften in a humid environment. Its function has three points: one is to prevent the mixed powder 8 in the cavity 3 from being lost during transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com