Separation purification method for rhTRAIL thalline

A technology for separation and purification of bacteria, applied in the field of separation and purification of rhTRAIL bacteria, can solve the problems of not being suitable for large-scale industrial production, long working cycle, high production cost, etc., and achieve effective quality control, high production efficiency, and convenience The effect of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

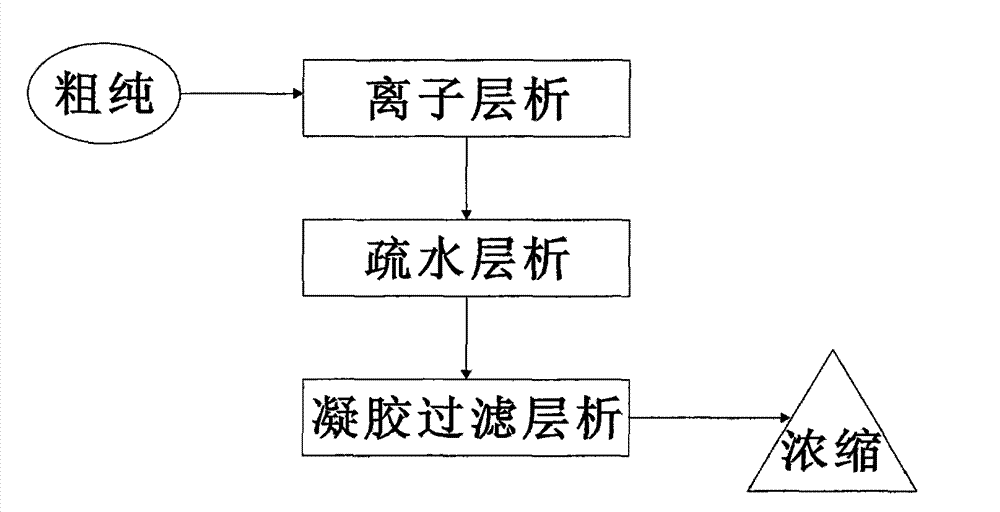

[0060] see figure 1 , according to the following steps, the sample rhTRAIL cells were isolated and purified:

[0061] Step 1: Crude Pure:

[0062] 1.1 High pressure homogenate crushing:

[0063] Weigh a certain amount of cryopreserved rhTRAIL cells and add an appropriate amount of B1 solution, mash them evenly with a tissue grinder until there are no lumps of cells, add an appropriate amount of B1 solution again to make the final cell concentration 10%, and mash The homogeneous bacterial suspension was crushed once under a pressure of 1500 bar, and the homogenized crushed liquid was collected and stored in a refrigerator at 4-8°C for later use.

[0064] The B1 solution is a buffer solution of 50mM / L Tris-HCl, pH8.5, and 0.1% DTT has been added according to the amount of bacteria before use; it is prepared with water for injection, and is sterilized and filtered with a 0.22um filter membrane after preparation.

[0065] 1.2 High-speed centrifugal separation

[0066] Centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com