Continuous-processing caprolactam polymerization kettle

A technology of caprolactam and polymerization kettle, applied in the field of polymerization kettle, can solve the problems of unfavorable reaction system material flow and mixing, inability to meet the needs of large-scale production, difference in quality of polymer products, etc., to achieve temperature uniformity in the kettle, and quality Uniformity, consistent response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

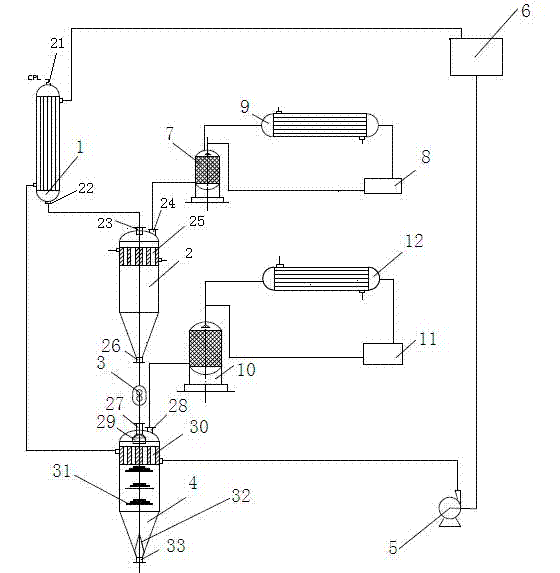

[0043] Such as figure 1 As shown, the present invention includes a polymerization kettle composed of a two-stage kettle body, the first section is a pressurized kettle body (2), and the second section is an atmospheric pressure kettle body (4). As its supporting device, it also includes a raw material preheater (1), a gear melt pump (3), a circulating oil pump (5) for the heat medium of the preheater, a high level tank (6), and a pressurized kettle body (2) Fractionation towers (7 and 10), impregnation tanks (8 and 11) and condensers (9 and 12) matched with the normal pressure still body (4).

[0044] Raw material preheater (1) The heat generated during the polymerization process is used as the raw material preheater, and the shell and tube heat exchanger is used to reduce resistance and facilitate the flow of raw materials; according to the scale of the subsequent polymerization tank, its capacity and heat transfer area.

[0045] The feed port (23) at the top of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com