Preparation method of CdSe/CdS core-shell structured quantum dot photocatalyst and application thereof

A photocatalyst, core-shell structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, nano optics, etc., can solve problems such as antibiotic residues in aquaculture products, achieve green environmental protection treatment technology, high-efficiency treatment technology, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of CdSe quantum dots:

[0025] Add 0.0592g Se powder to 20mL1.2mol / L Na 2 SO 3 Magnetic stirring in the solution was heated to boiling to obtain Na 2 SeSO 3 solution; 0.0913g CdCl 2 2.5H 2 O and 0.0975g of thiomalic acid were added to 20mL of deionized water and mixed, and the pH of the solution was adjusted to 7 with 1mol / L NaOH, and under the protection of nitrogen, new Na 2 SeSO 3 solution, the oil bath was heated to 100 o C, reflux for 1 hour, and cool to room temperature.

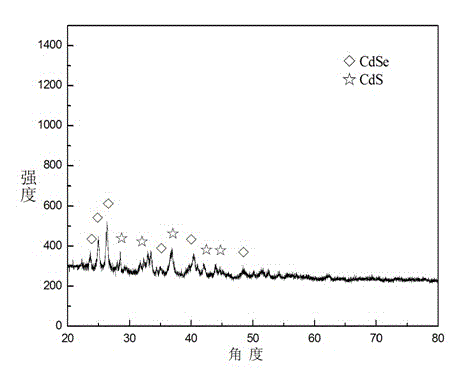

[0026] (2) Preparation of CdSeCdS core-shell quantum dot photocatalyst:

[0027] Weigh 0.0913g CdCl 2 2.5H 2 O was dissolved and added to the solution prepared in step (1), and stirred for 30 min. After adding 0.079g sodium thiosulfate and stirring for 30min, 100 o C was refluxed for 1 hour, cooled to room temperature, centrifuged, and dried to obtain a CdSeCdS core-shell structure quantum dot photocatalyst, wherein the molar ratio of CdSe to CdS was 1:1.

[002...

Embodiment 2

[0030] (1) Preparation of CdSe quantum dots:

[0031] According to the steps in Example 1, the difference is that the pH=8 of the solution is adjusted in step (1), and under the protection of nitrogen, the newly prepared Na 2 SeSO 3 solution, the oil bath was heated to 100 o C, reflux for 2 hours, and cool to room temperature.

[0032] (2) Preparation of CdSeCdS core-shell quantum dot photocatalyst:

[0033] Weigh 0.0913g CdCl2 2.5H 2 O was dissolved and added to the solution prepared in step (1), and stirred for 30 min. After adding 0.079g sodium thiosulfate and stirring for 30min, 100 o C was refluxed for 1 hour, cooled to room temperature, centrifuged, and dried to obtain a CdSeCdS core-shell structure quantum dot photocatalyst, wherein the molar ratio of CdSe to CdS was 1:1.

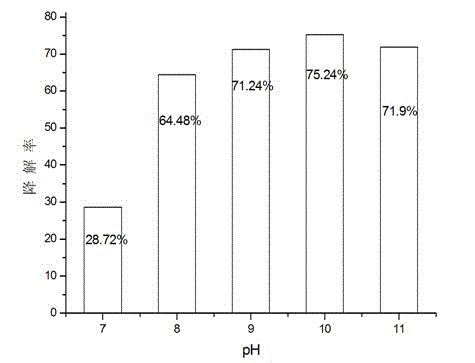

[0034] (3) Take the sample in step (2) and carry out the photocatalytic degradation test in the photochemical reaction instrument, and it is measured that the degradation rate of the tetracyc...

Embodiment 3

[0036] (1) Preparation of CdSe quantum dots:

[0037] According to the steps in Example 1, the difference is that the pH=9 of the solution is adjusted in step (1), and under the protection of nitrogen, the newly prepared Na 2 SeSO 3 solution, the oil bath was heated to 100 o C, reflux for 3 hours, and cool to room temperature.

[0038] (2) Preparation of CdSeCdS core-shell quantum dot photocatalyst:

[0039] Weigh 0.0913g CdCl 2 2.5H 2 O was dissolved and added to the solution prepared in step (1), and stirred for 30 min. After adding 0.079g sodium thiosulfate and stirring for 30min, 100 o C was refluxed for 1 hour, cooled to room temperature, centrifuged, and dried to obtain a CdSeCdS core-shell structure quantum dot photocatalyst, wherein the molar ratio of CdSe to CdS was 1:1.

[0040] (3) Take the sample in step (2) and carry out the photocatalytic degradation test in the photochemical reaction apparatus, and it is measured that the degradation rate of the tetracy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com