Stone material sewage treatment system and method thereof

A sewage treatment system and sewage technology, applied in the field of waste pollutant treatment systems, can solve the problems of low recycling rate, complicated operation and poor treatment effect, etc., and achieve fast sewage treatment speed, high recycling rate, and clean water. good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

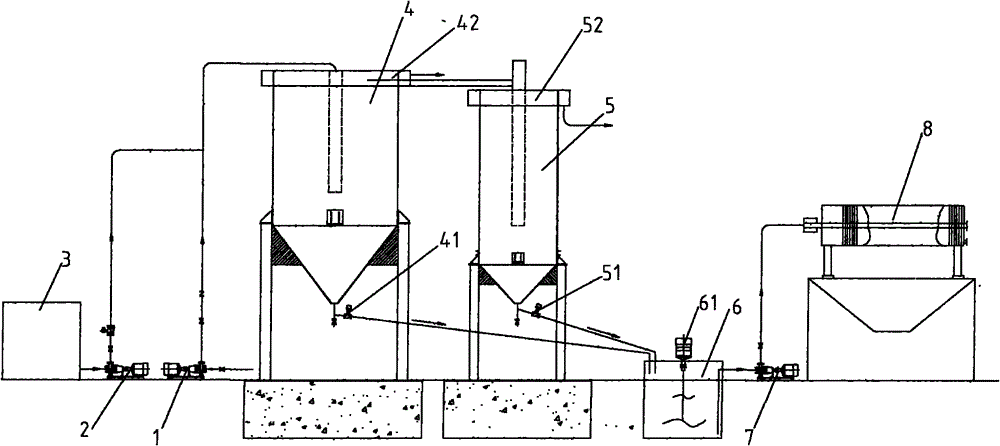

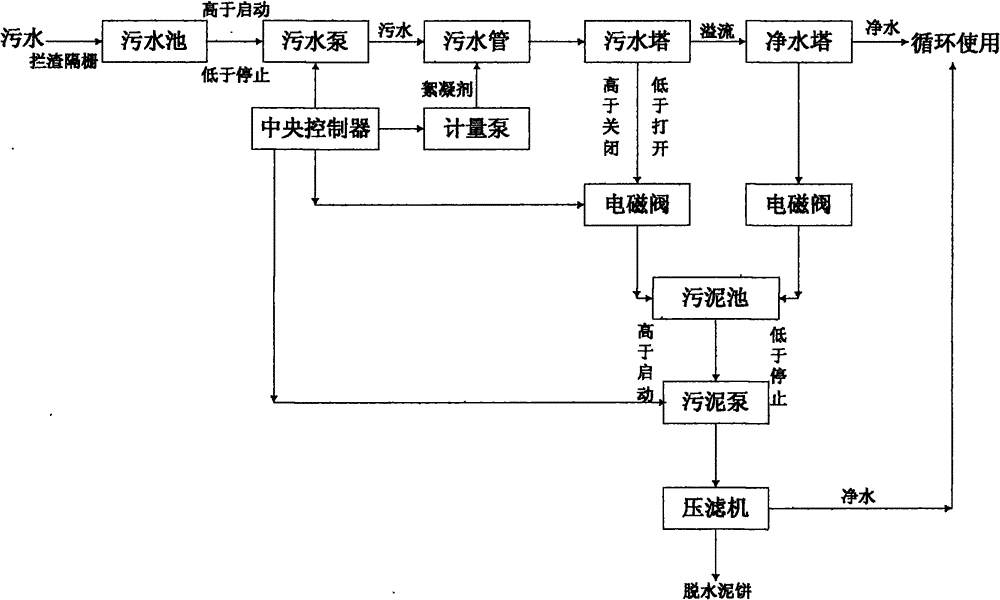

[0027] Example 1, such as figure 1 As shown, this embodiment discloses a stone sewage treatment system. The sewage flows into the sewage pool after being filtered by the slag-retaining grid. There are upper limit liquid level sensors and lower limit liquid level sensors in the sewage pool. The central controller receives the signals of the above sensors and controls Sewage pump 1 starts when the sewage liquid level in the sewage tank is higher than the upper limit liquid level sensor, injects sewage into the sewage pipe, and stops when it is lower than the lower limit liquid level sensor. The metering pump 2 injects the flocculant into the sewage pipe. The pump pressure in the metering pump must be greater than the water pressure in the sewage pipe, and a one-way valve is set to prevent the sewage from recoil after the pump is stopped. An electromagnetic flowmeter is installed in the sewage pipe, and the central controller According to the sewage flow rate transmitted by the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap