Energy-saving emission-reducing type asphalt mixture and preparation method thereof

An asphalt mixture, energy saving and emission reduction technology, applied in the engineering field, to achieve the effect of reducing production and construction temperature, good economic and social benefits, and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

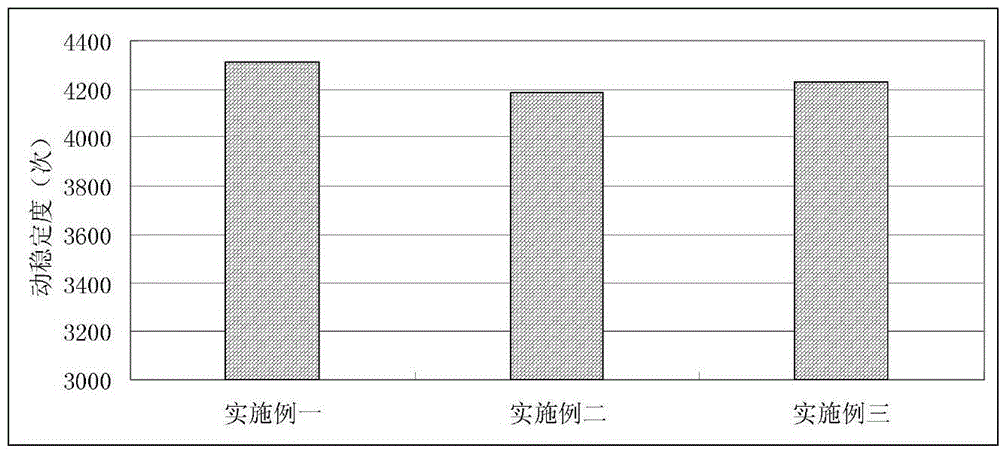

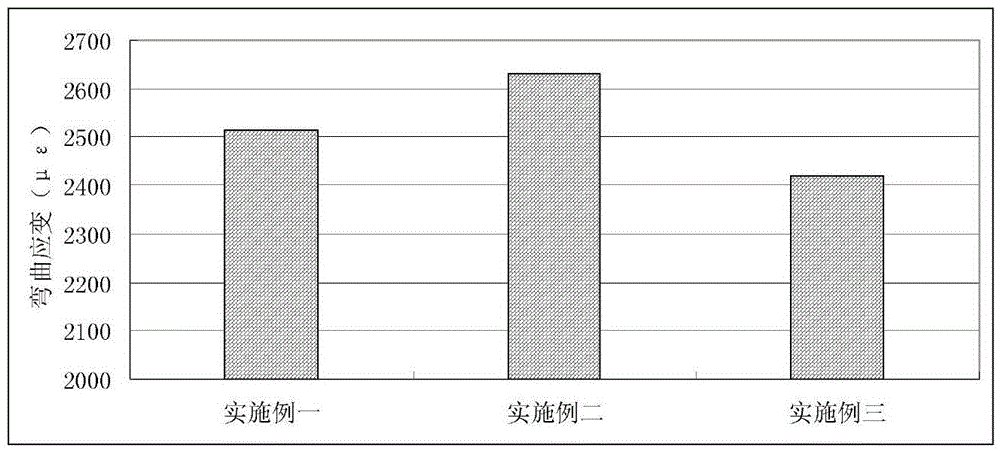

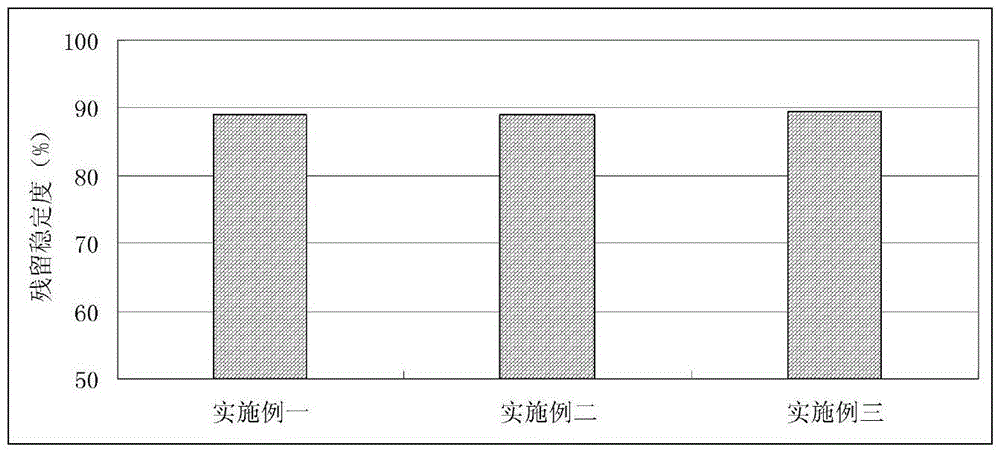

Embodiment 1

[0025] Example 1 Preparation of SMA-13 warm mix foamed asphalt mixture

[0026] 1. Material preparation:

[0027] The asphalt is modified asphalt, and the SBS modified asphalt produced by Jiangsu Baoli Asphalt Co., Ltd. is used in this embodiment.

[0028] Crushed stone aggregate, also known as aggregate. One of the main components of asphalt concrete, it mainly acts as a skeleton and reduces the volume change caused by the shrinkage and swelling of the cementitious material during the setting and hardening process, and is also used as a cheap filler for the cementitious material. There are natural aggregates and artificial aggregates, the former such as gravel, pebbles, pumice, natural sand, etc.; the latter such as cinder, slag, ceramsite, expanded perlite, etc. The stone material used in this example is sieved crushed stone, and the crushed stone aggregate is classified according to the commonly used classification requirements. 9.5 ~ 16mm, the ratio of each file is: 2...

Embodiment 2

[0037] Example 2 Preparation of AC-13 warm mix foamed asphalt mixture

[0038] 1. Material preparation:

[0039] The asphalt is modified asphalt, and the SBS modified asphalt produced by Jiangsu Baoli Asphalt Co., Ltd. is used in this embodiment.

[0040] For crushed stone aggregates, the crushed stone aggregates are graded according to the commonly used classification requirements. The grades used in this embodiment are: 0-2.36mm, 2.36-4.75mm, 4.75-9.5mm and 9.5-16mm. The ratio is: 28.30% : 15.20% : 30.40% : 26.10%, and they are added at the same time.

[0041] Limestone slag, mainly composed of calcium carbonate, requires limestone slag processed from limestone.

[0042] Bitumen 5.3%

[0043] Crushed stone aggregate 88.7%

[0044] Limestone Mineral Powder 6%

[0045] 2. Prepare the energy-saving and emission-reducing asphalt mixture with the above materials according to the following steps:

[0046] Step 1: add crushed stone aggregates to limestone powder in proportion...

Embodiment 3

[0049] Example 3 Preparation of SUP-13 warm mix foamed asphalt mixture

[0050] 1. Material preparation:

[0051] The asphalt is modified asphalt, and the SBS modified asphalt produced by Nantong Tongsha Asphalt Technology Co., Ltd. is used in this embodiment.

[0052] For crushed stone aggregates, the crushed stone aggregates are graded according to the commonly used classification requirements. The grades used in this embodiment are: 0-2.36mm, 2.36-4.75mm, 4.75-9.5mm and 9.5-16mm. The ratio is: 31.10% : 16.50% : 41.60% : 10.80%, and they are added at the same time.

[0053] Limestone slag, mainly composed of calcium carbonate, requires limestone slag processed from limestone.

[0054] Bitumen 5.5%

[0055] Crushed stone aggregate 88.5%

[0056] Limestone Mineral Powder 6%

[0057] 2. Prepare the energy-saving and emission-reducing asphalt mixture with the above materials according to the following steps:

[0058] Step 1: add crushed stone aggregates to limestone powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com