Keratinase with improved thermal stability and specific activity as well as preparation method and application thereof

A technology of keratinase and heat stability, applied in the field of genetic engineering, can solve problems such as polluting the environment, reducing the nutritional value of products, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The keratinase that embodiment 1 thermostability improves

[0024] The keratinase of the present invention is based on the gene sequence published by GenBank accession nos. JX504681, and carries out molecular transformation in the cleavage site region of its leader peptide, specifically the C-terminal (-1) site Leu of the leader peptide is replaced with Ala, and the mature The N-terminal AQTVP of the enzyme was replaced by the N-terminal YTPNDPYFSSRQ of the thermophilic protease derived from Thermoactinomyces vulgaris. The method of obtaining it is to use the gene published by GenBank accession nos. JX504681 as the starting gene, and carry out amino acid substitution in the cleavage site region of the leading peptide by chemical total synthesis or site-directed mutagenesis; the amino acid sequence is shown in SEQ ID NO.1.

Embodiment 2

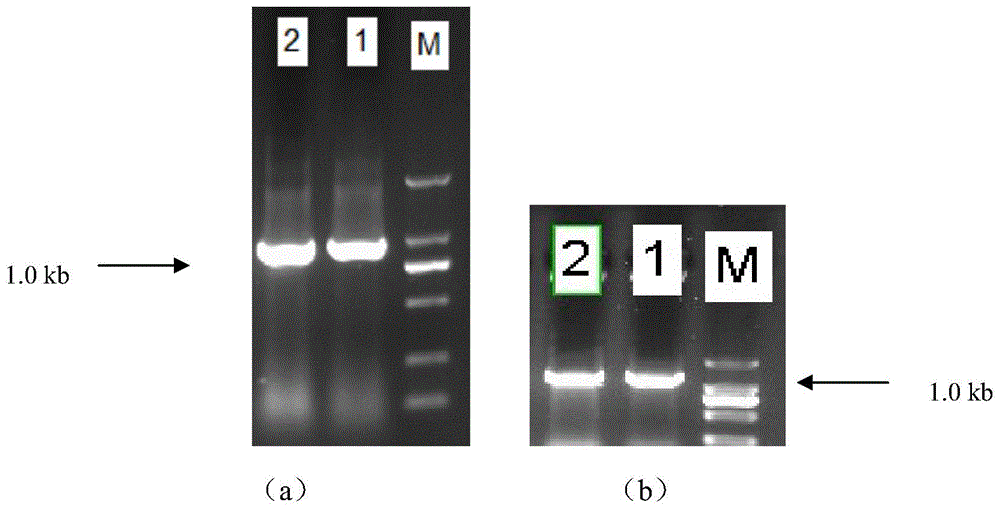

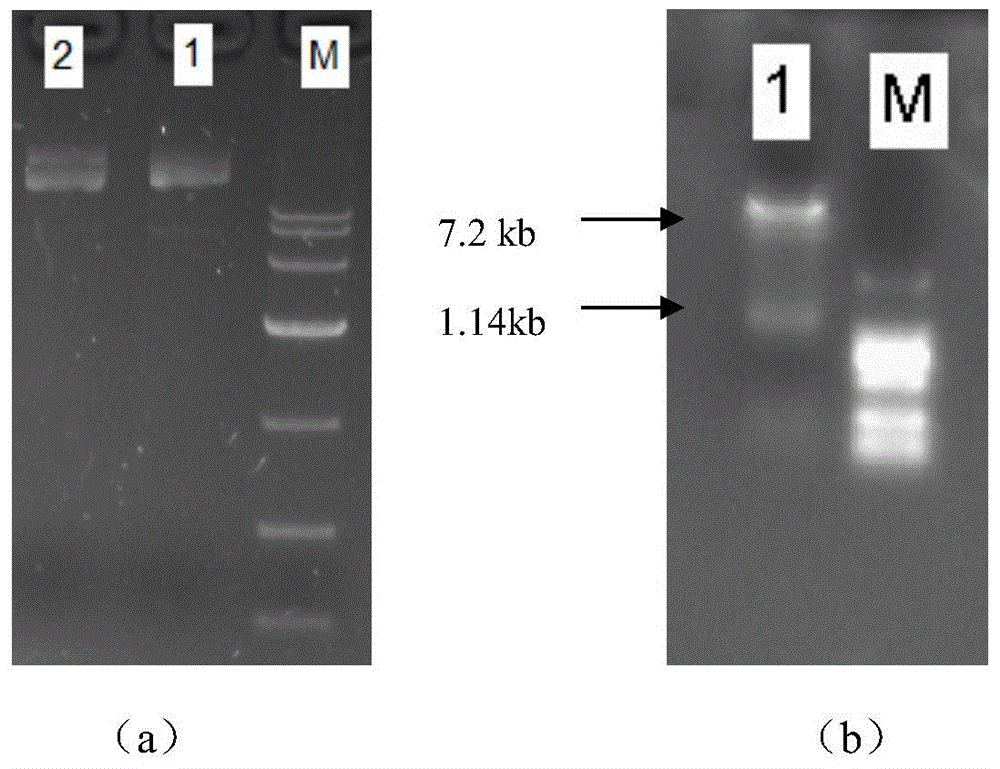

[0025] Construction and identification of embodiment 2 producing keratinase genetically engineered bacteria

[0026] The steps of constructing keratinase genetically engineered bacteria are as follows:

[0027] 1) The ker gene is obtained by PCR method or chemical total synthesis method;

[0028] 2) Link the ker gene to the cloning vector pMD19-T to obtain the recombinant vector pMD19-T-ker;

[0029] 3) Leu at the C-terminal (-1) site of the leader peptide was replaced with different types of amino acids. The N-terminal AQTVP of the mature enzyme was replaced by the N-terminal YTPNDPYFSSRQ (N-YPTND) of a thermophilic protease derived from Thermoactinomyces vulgaris.

[0030] The mutation can adopt site-directed mutagenesis technique or other techniques, as long as the mutation can be realized.

[0031] This patent lists the primers of Leu(-1)Ala as an example:

[0032] Leu(-1)Ala: GATCATGTGGCCCATGCC TTG (GCA)GCGCAAACCGTTCCTTACN-YPTND:

[0033] TATACGCCTAATGACCCTTATTTC...

Embodiment 3

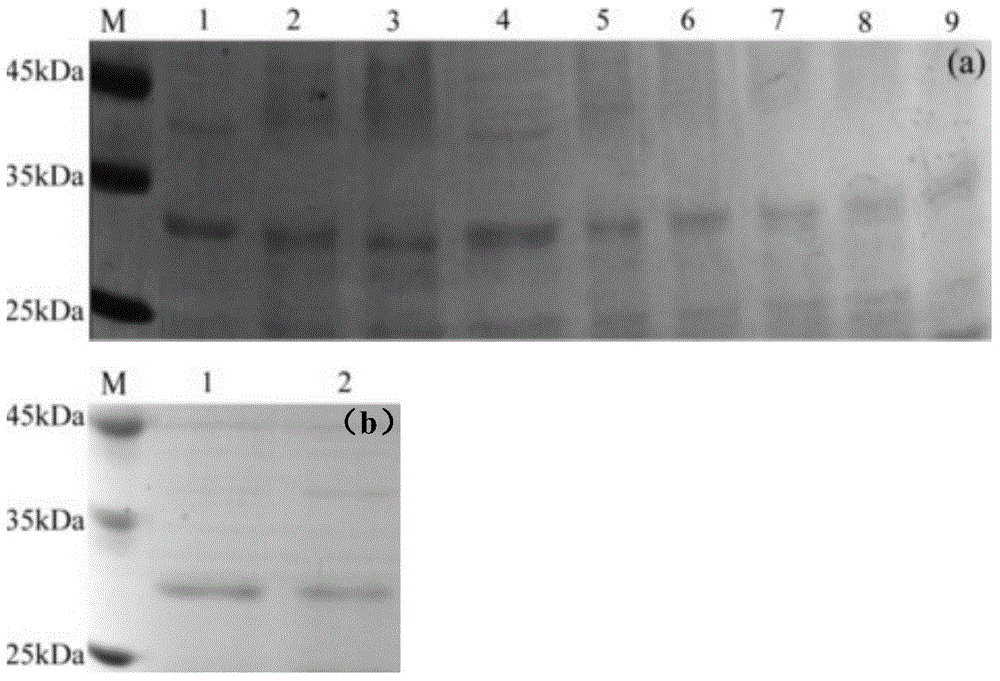

[0047] Enzyme activity assay and protein electrophoresis of embodiment 3 recombinant bacteria

[0048] Keratinase activity assay method: Centrifuge the fermentation broth for 10min (10000×g, 4°C) to take the fermentation supernatant, absorb 200μL of appropriately diluted enzyme solution, add 300μL of 0.05mol / L gly-NaOH buffer (pH9.0) Dissolve 1% of the substrate (keratin), incubate at 50°C for 20min, add 500uL 4M TCA solution to terminate the reaction. Centrifuge for 10 minutes, pipette 200 μL of supernatant into a new test tube, and then add 1 mL of folinol reagent and 200 μL of 0.5M Na 2 CO 3 Then develop color at 50 degrees for 15 minutes. For the blank, 500 μL of TCA solution was added at the same time as the enzyme solution was added, and the filtered clear liquid reacted through the same process was used as a blank. The absorbance was detected at 660nm, and according to the definition of the tyrosine standard curve, 1 μg of tyrosine was released every 15 minutes, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com