Method for producing ferrosilicon alloy by use of silica fume

A technology of ferrosilicon alloy and micro-silicon powder, applied in the field of ferrosilicon alloy production, can solve the problems of occupying the production area, environmental pollution around the factory, waste of silicon ore resources, etc., to solve environmental problems, reduce the amount of silica, and improve the economic benefits of enterprises Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

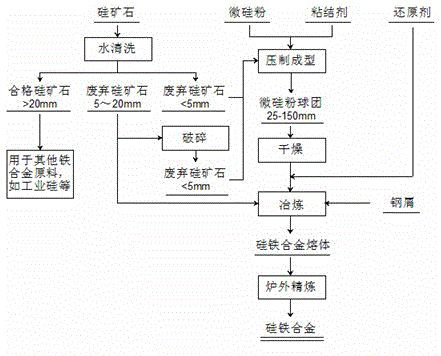

[0028] Such as figure 1 As shown, the method for producing ferrosilicon alloy using micro-silicon powder, its concrete steps are as follows:

[0029] (1) First, add a binder of 2% mass of microsilica fume and water of 3% mass of microsilica fume to microsilica fume and small particle silica, mix evenly, and press it into pellets under a pressure of 5t, in which microsilica SiO in powder 2 Content 90.4wt.%, Al 2 o 3 The content is 1.2wt.%, the particle size of small particles of silica is less than 5mm, the amount added is 40% of the mass of silica fume, the binder is coal tar, and the particle size of pellets is 25mm;

[0030] (2) Under a reducing atmosphere, after drying the pellets obtained in step (1) at a temperature of 100°C for 6 hours, put the dried pellets and carbonaceous reducing agent with a mass ratio of 2.4:1.0 into the surface temperature In a metallurgical furnace with a temperature of 800°C, the pellets and carbonaceous reducing agent are pre-roasted during...

Embodiment 2

[0036] Such as figure 1 As shown, the method for producing ferrosilicon alloy using micro-silicon powder, its concrete steps are as follows:

[0037] (1) First, add a binder of 12% of the mass of microsilica fume and water of 15% of the mass of microsilica fume to the microsilica fume and small-grained silica, mix them evenly, and press them into pellets under a pressure of 30t, in which microsilica SiO in powder 2 Content 88.5wt.%, Al 2 o 3 The content is less than 1.4wt.%, the particle size of small particles of silica is less than 5mm, the amount added is less than 50% of the mass of microsilica fume, the binder is coal tar pitch and wood fiber with a mass ratio of 1:1, and the particle size of pellets is 150mm;

[0038] (2) Under a reducing atmosphere, after drying the pellets obtained in step (1) at a temperature of 300°C for 0.5 h, put the dried pellets and carbonaceous reducing agent with a mass ratio of 3.0:2.0 on the surface In a metallurgical furnace with a temp...

Embodiment 3

[0045] Such as figure 1 As shown, the method for producing ferrosilicon alloy using micro-silicon powder, its concrete steps are as follows:

[0046] (1) First, add a binder of 8% of the mass of microsilica fume and water of 10% of the mass of microsilica fume to the silica fume and small particles of silica, mix evenly, and press it into pellets under a pressure of 15t, in which microsilica SiO in powder 2 Content 86.3wt.%, Al 2 o 3 The content is 1.2wt.%, the particle size of small particles of silica is less than 5mm, the amount added is 48% of the mass of microsilica fume, the binder is coal tar, and the particle size of pellets is 100mm;

[0047] (2) Under a reducing atmosphere, after drying the pellets obtained in step (1) at a temperature of 150°C for 4 hours, put the dried pellets and carbonaceous reducing agent with a mass ratio of 2.5:1.5 into the surface temperature In a metallurgical furnace with a temperature of 900°C, the pellets and carbonaceous reducing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com