Method and device for welding high-silicon non-oriented electrical steel hot rolled plate

A technology for grain-oriented electrical steel and hot-rolled sheet, applied in the field of metal rolling, can solve the problems of connecting silicon-free hot-rolled sheets, etc., and achieve the effects of improving welding quality, improving performance, and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

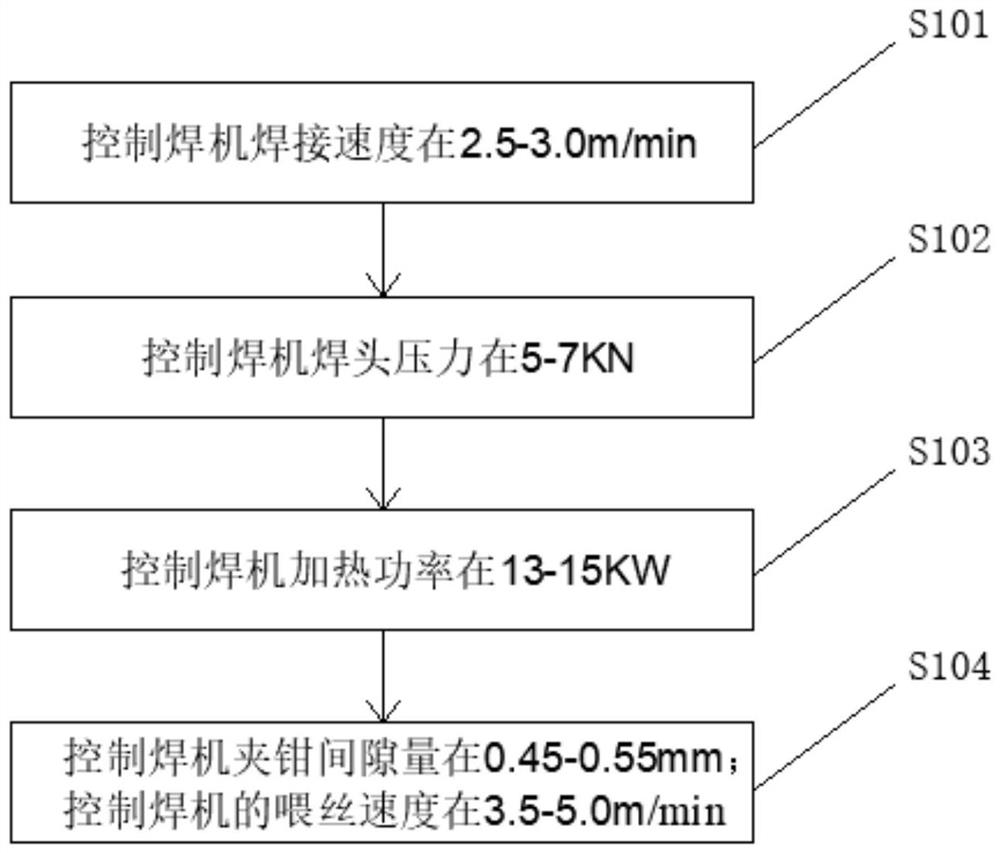

[0034] After repeated research on the production line, continuous comparison and improvement of the process, combined with the attached figure 1 , Embodiment 1 proposes a method for welding a high-silicon non-oriented electrical steel hot-rolled sheet, including the following steps when butt welding two high-silicon strip steels in the normalization process:

[0035] The thermal properties of the high-silicon strip steel are stable. If the heating time is insufficient, the penetration depth will be insufficient, and the absorbed laser energy will be too low. In the subsequent welding process, only the surface of the high-silicon strip steel will be heated and softened, while the middle part is too hard to be welded; if The heating time is too long, which leads to the deformation of the high-silicon strip steel, which also causes waste of production capacity. After repeated verification, by changing the welding speed, record and compare the relationship between the welding machi...

Embodiment 2

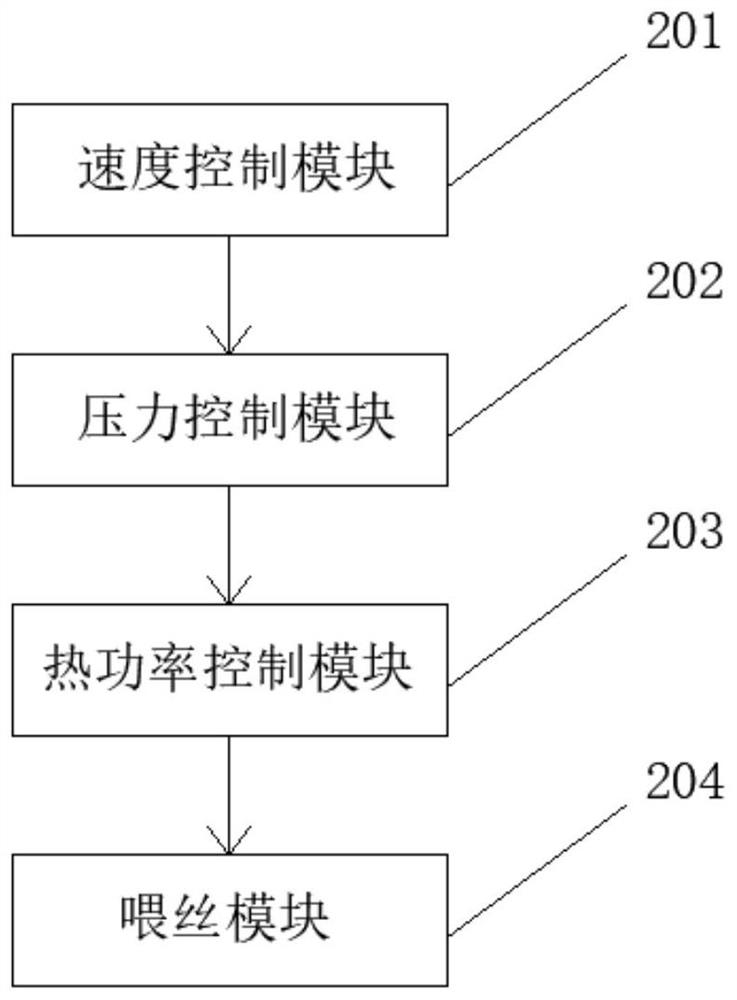

[0041] The difference from Example 1 is that the high-silicon strip goes through the smelting process and the hot-rolling process in turn, and after entering the normalization process, a high-silicon non-oriented electrical steel hot-rolled by the high-silicon non-oriented electrical steel provided in Example 2 is used for the high-silicon strip. Device for stable welding of plates, combined with attachment figure 2 , the device includes:

[0042] The speed control module 201 controls the welding speed of the welding machine to be 2.5-3.0 m / min, and melts the high-silicon strip to 95% of the thickness of the high-silicon strip;

[0043] The pressure control module 202 controls the pressure of the welding head of the welding machine at 5-7KN to flatten and melt the high silicon strip steel;

[0044] The heating power control module 203 controls the heating power of the welding machine at 13-15KW to improve the strength of the flat high silicon strip;

[0045] The wire feedin...

Embodiment 3

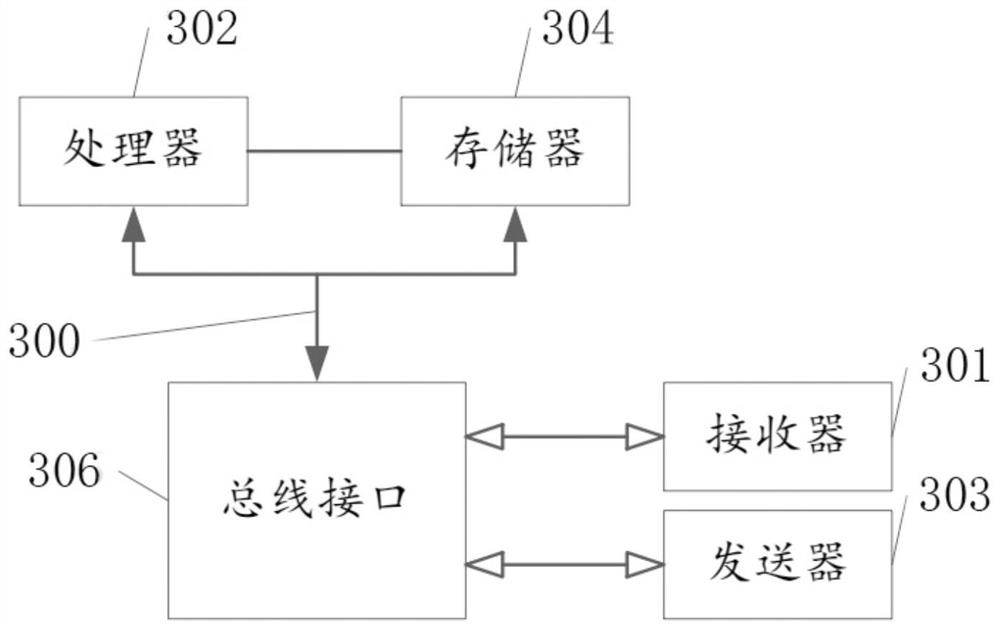

[0049] Based on the same inventive concept, Embodiment 3 of the present application provides an electronic device, such as image 3 As shown, a memory 304, a processor 302 and a computer program stored in the memory 304 and running on the processor 302 are included, and the processor 302 implements the steps of the above directed graph drawing method when executing the program.

[0050] Among them, in image 3 In the bus architecture (represented by bus 300 ), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits are linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be described further herein. Bus interface 306 provides an interface between bus 300 and receiver 301 and transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com