Method for efficiently preparing lubricant additive T321 in pollution-free manner by employing medium-pressure solvothermal method

A technology of lubricating oil additives and solvothermal method, which is applied in the field of organic sulfide synthesis, can solve the problems of high equipment requirements, serious environmental pollution, and difficulty in control, and achieve the effects of reducing pollution, reducing production costs, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

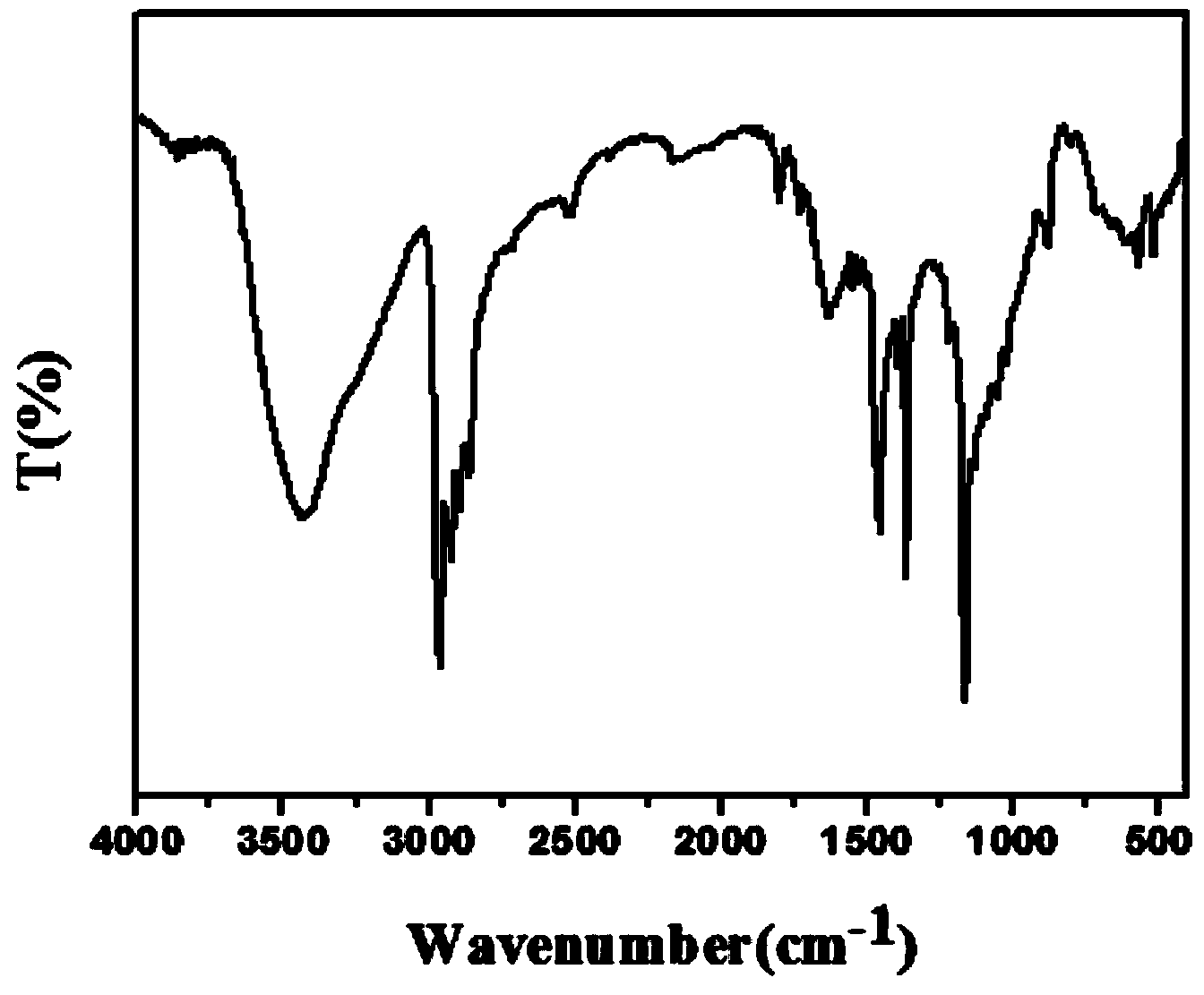

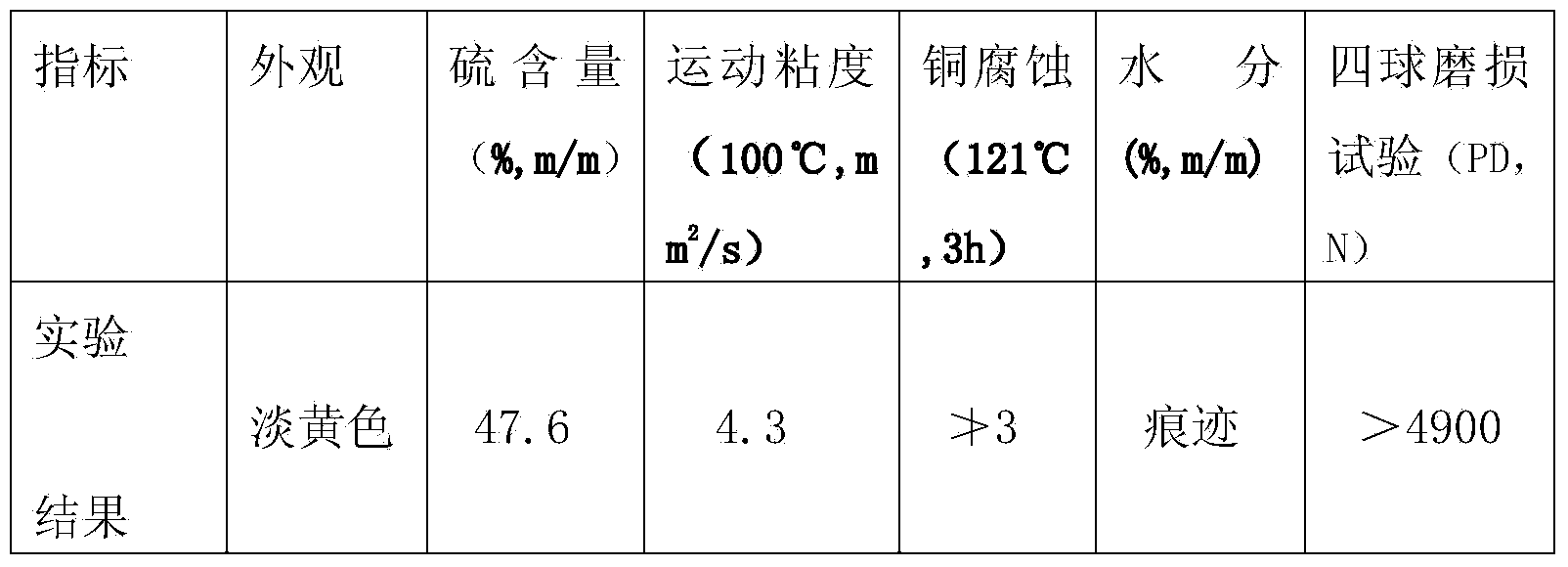

[0026] The ratio of sulfur to ene is 2:1. Add 9.71Kg of elemental sulfur into the reactor, 18Kg of solvent with a mass fraction of 5% ammonia water and an alcohol ratio of 9:1, raise the temperature to 200°C, add 8.5Kg of isobutylene intermittently, and keep the pressure at 3.5-4.5MPa After the addition, the reaction was continued for 6 hours, and then cooled to 60°C, and the mixture was pressed out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed and distilled to obtain the lubricating oil additive T321 product with a yield of 90%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling. The product obtained in this embodiment is analyzed to obtain an infrared spectrogram ( figure 1 ), the gas chromatogram ( figure 2 ).

[0027] Synthetic lubricating oil additive T321 specification...

Embodiment 2

[0030] Sulfurene ratio 1.5:1. Add 7.29Kg of elemental sulfur into the reactor, 18Kg of solvent with a mass fraction of 10% ammonia water and alcohol in a ratio of 9:1, raise the temperature to 180°C, add 8.5Kg of isobutylene intermittently, and keep the pressure at 3.5-4.5MPa After the addition, the reaction was continued for 5 hours, and then cooled to 60°C, and the mixture was pressed out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed and distilled to obtain the lubricating oil additive T321 product with a yield of 88%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling.

[0031] Synthetic lubricating oil additive T321 specification parameters are as follows:

[0032]

Embodiment 3

[0034] Sulfurene ratio 1.5:1. Add 7.29Kg of elemental sulfur into the reactor, 18Kg of solvent with a mass fraction of 10% ammonia water and alcohol in a ratio of 9:1, raise the temperature to 200°C, add 8.5Kg of isobutylene intermittently, and keep the pressure at 3.5-4.5MPa After the addition, the reaction was continued for 4 hours, and then cooled to 60°C, and the mixture was pressed out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed and distilled to obtain the lubricating oil additive T321 product with a yield of 85%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling.

[0035]

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com